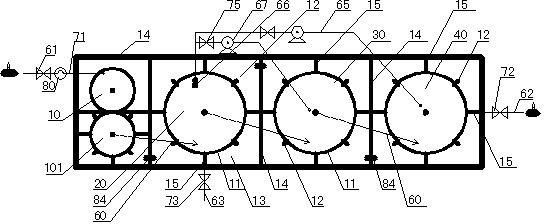

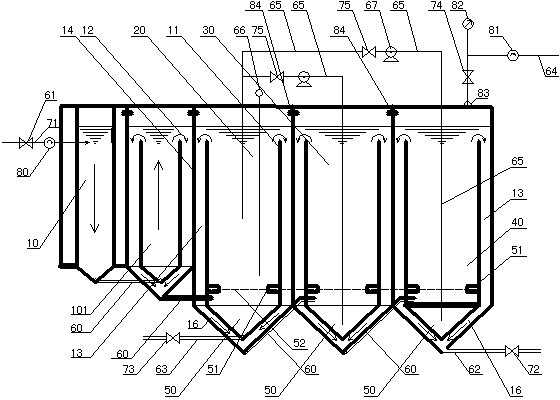

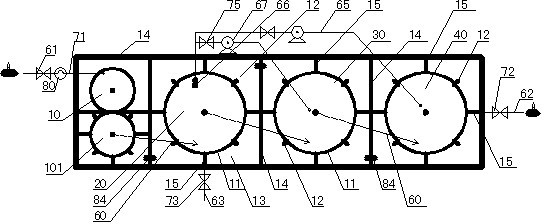

Special diversion anaerobic baffled reactor

An anaerobic reactor and baffle-type technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of failure to reach the stage of large-scale practical application, few reports on engineering design and operation, and achieve stable treatment efficiency , short start-up time, enhanced contact mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] (1) Anaerobic treatment of sewage

[0019] The pretreated sewage enters the acidification-anaerobic zone 10 through the water inlet pipe 61, the water inlet valve 71, and the liquid flow meter 80, enters from the upper edge, forms a circular water flow and flows downward. The flow descends to the center of the lower conical bottom, and is connected to the center of the upflow conical bottom of the acidification secondary anaerobic zone 101 by the guide pipe 60 and then flows upward. Upflow to the upper part through the diversion port 12 and downflow. The downflow to the lower gathering tank 16 enters through the guide pipe 60 and enters from the upper edge of the anaerobic zone two mixer 50 . In order to prevent the operation from being affected by excessive water flow rate, a buffer plate 51 is provided on the upper end of the mixer 50, and an overflow hole 52 is opened in the center of the buffer plate 51 to buffer the water flow to ascend smoothly. The heavy part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com