Automatic deslagging multi-cycle anaerobic reactor

An anaerobic reactor and automatic slag removal technology, which is applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of low wastewater treatment efficiency, gas pollution in the external area, lack of cooperation with large flow circulation devices, etc., and achieve cycle strength improvement , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

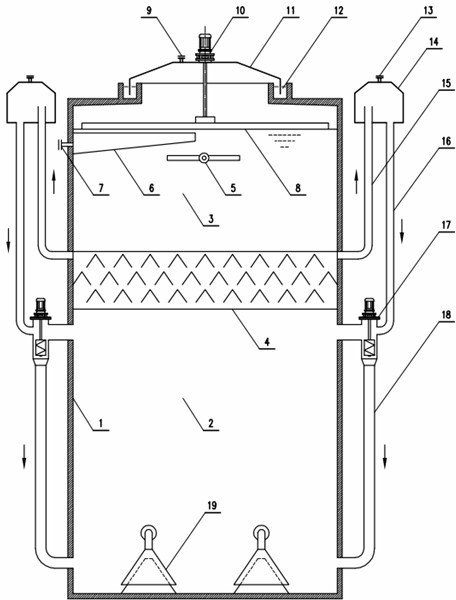

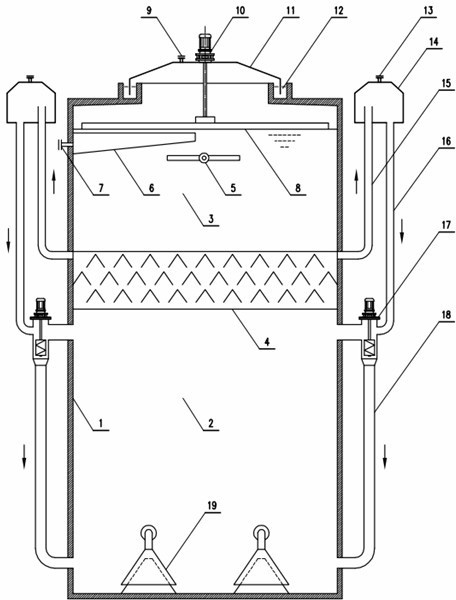

[0022] Such as figure 1 As shown, an automatic slag removal multi-cycle anaerobic reactor of the present invention mainly includes an anaerobic reactor main body 1, which may be cylindrical or rectangular in shape. In the middle of the inner cavity of the main body 1 of the anaerobic reactor, a multi-layer triangular mud separator 4 is arranged, and the multi-layer triangular mud separator 4 is arranged at 1 / 2 to 2 / 3 of the anaerobic reactor main body 1 from the bottom. The inner cavity is divided into an upper sedimentation separation zone 3 and a lower high-efficiency reaction zone 2 by the triangular mud separator 4. A water distribution device 19 is installed in the high-efficiency reaction zone 2 near the bottom of the main body of the anaerobic reactor; and the sedimentation separation zone 3 is provided Water collection device 6.

[0023] The top of the main body 1 of the anaerobic reactor is provided with a detachable gas collecting hood 11, and a water sealing groove 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com