Automobile provided with backwards extending front windshield

A front windshield and automobile technology, applied to the windshield, vehicle parts, superstructure, etc., can solve the problems that the overall strength of the A-pillar area of the automobile cannot be increased, the living space of the occupants is reduced, and the A-pillar area of the automobile is too large to shrink, etc. Achieve the effect of bold conception, low implementation cost, and solving collision safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

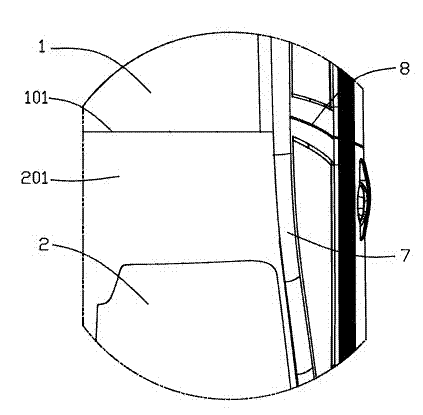

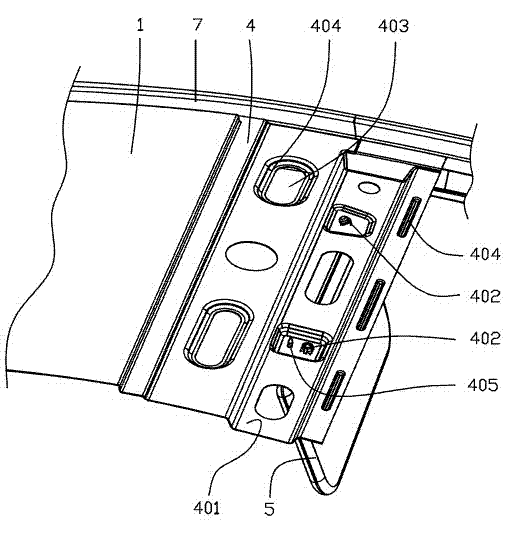

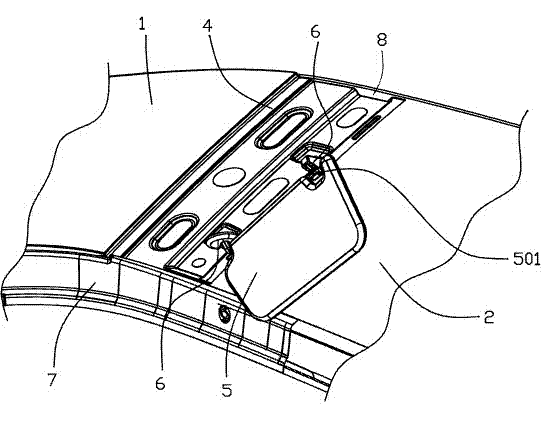

[0016] see figure 1 and Figure 4 , a car with a front windshield extending backwards, comprising A-pillars 7 on the left and right sides of the car, a roof front beam 3, a roof outer panel 1, a front windshield 2 and an interior trim panel 10. Wherein, the left and right side A-pillars 7 and the top cover front beam 3 form the frame of the front windshield glass 2 , and the front windshield glass 2 is sealed and arranged on the frame by a sealing strip 11 . The parting line 101 formed by the connection of the front windshield glass 2 and the top cover outer panel 1 is close to the B-pillar 8 of the car, so that the front windshield glass 2 extends backward, increases the area of the front windshield glass, and highlights the sporty fashion elements of the car.

[0017] The front beam 3 of the roof is located on the inner surface of the outer panel 1 of the roof and close to the parting line 101 . The cross-section of the front beam 3 of the top cover is U-shaped, and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com