Bottom door opening and closing air control system for railroad hopper car

A technology of air control system and bottom door opening and closing, which is applied in the direction of hopper cars, railway car body parts, transport passenger cars, etc. It can solve the problems of complex pneumatic control principles, inability to automatically interlock, damage to the reducer, etc., and achieve simple structure, Avoid misuse damage and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

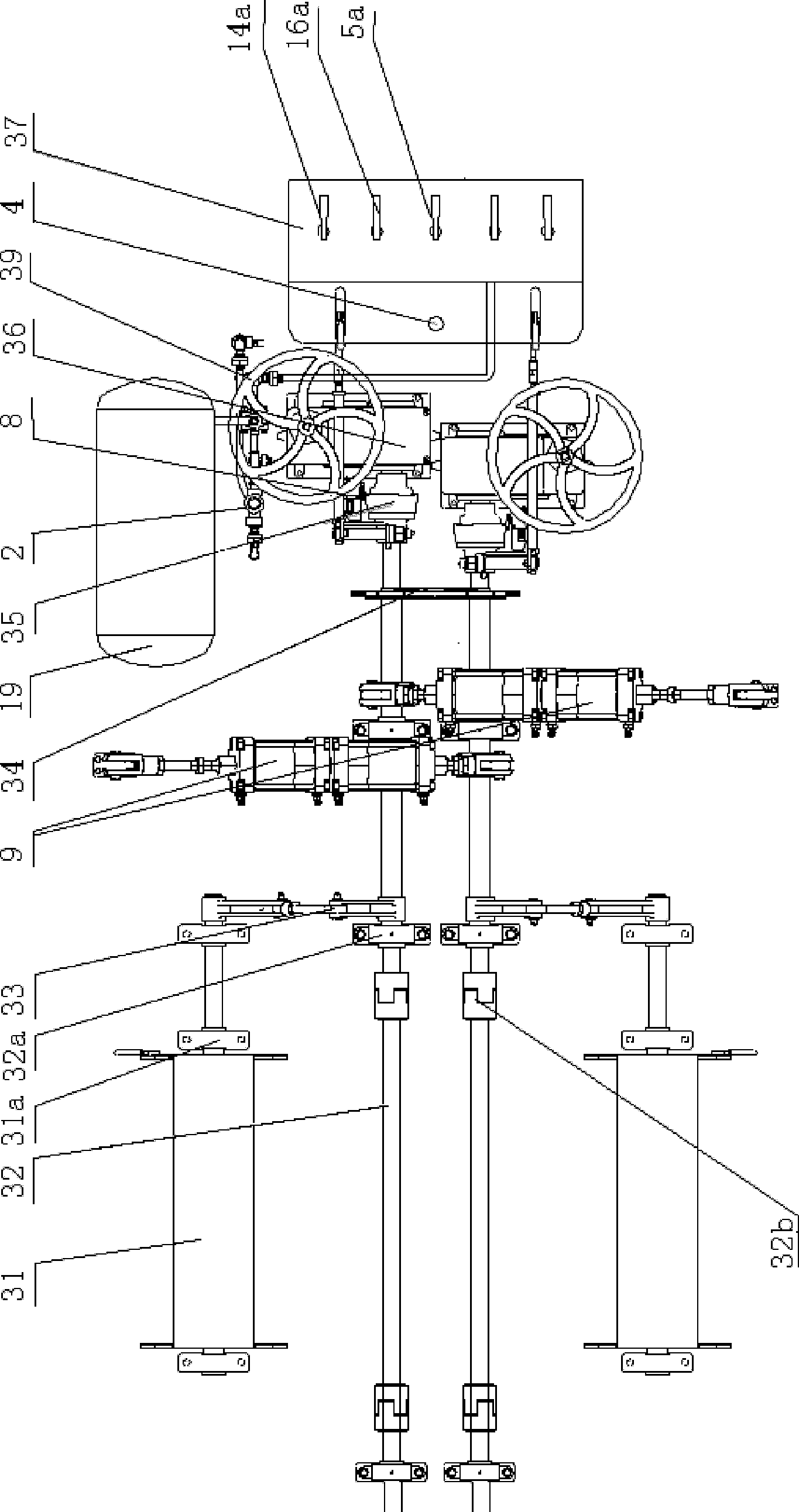

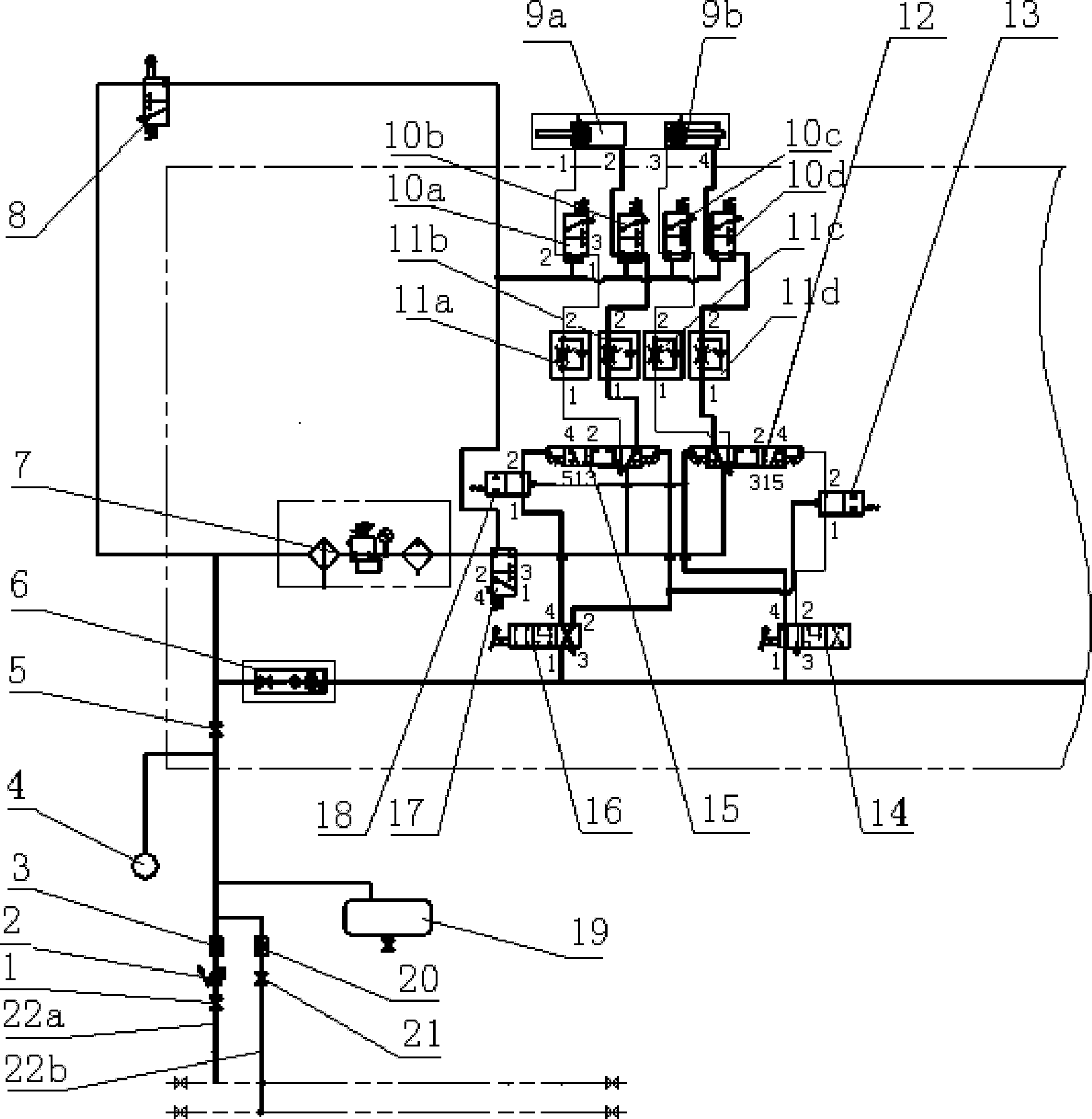

[0031] The hopper car involved in the present invention is provided with four bottom doors, which are divided into two groups, and the two doors on the same side form a group, and each group is independently controlled. In the present invention, one group is described, and the other group is the same.

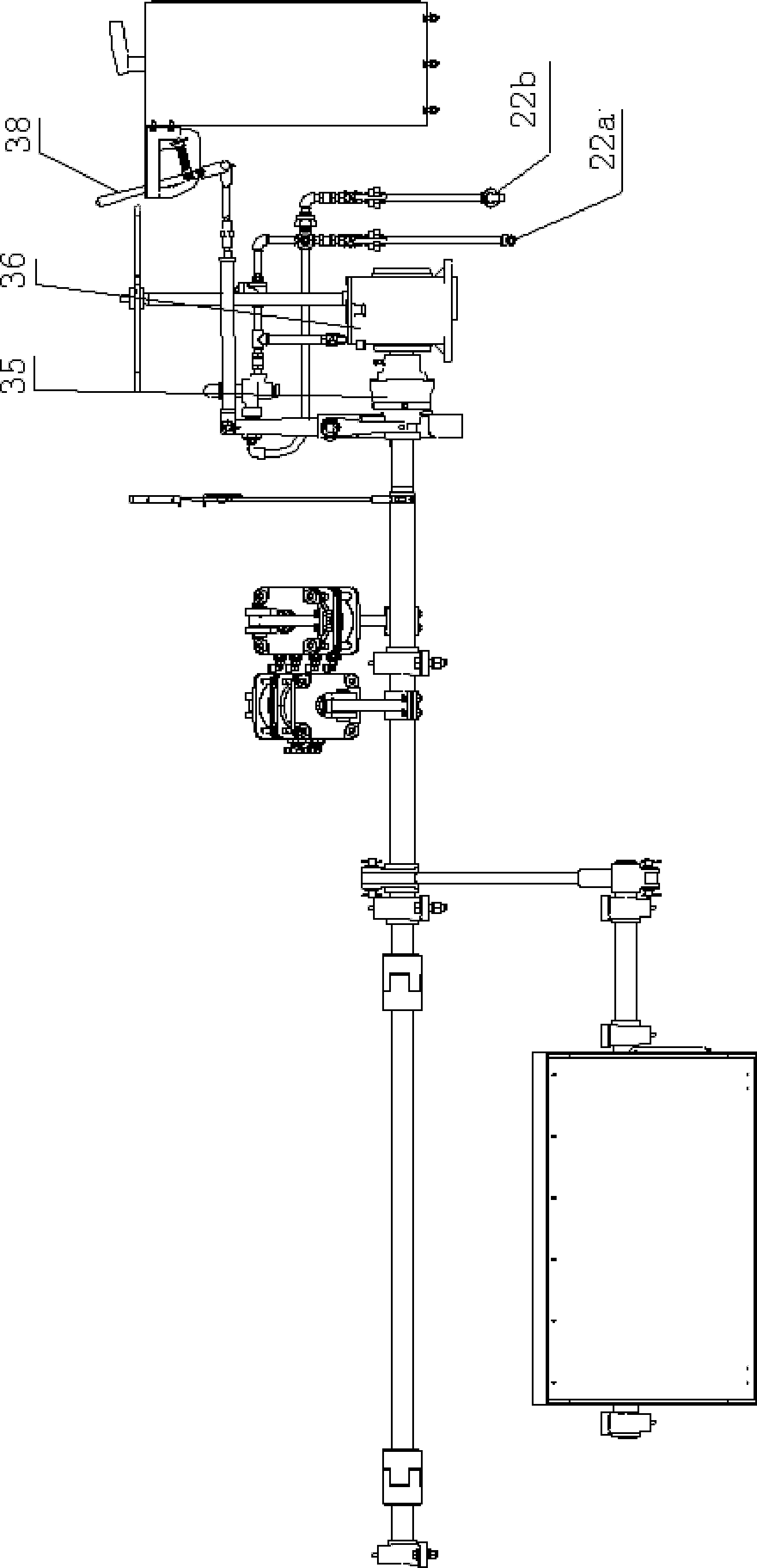

[0032] Such as figure 1 , figure 2 The present invention has bottom door 31, and bottom door opening and closing mechanism comprises transmission shaft 32 that is connected with pneumatic system, and transmission shaft 32 is connected with bottom door 31 by bell crank connecting rod 33, and transmission shaft 32 is fixed by the transmission shaft bearing 32a of band seat On the upper plane of the vehicle underframe, the bottom door 31 is fixed below the underframe by the bottom door bearing 31a with seat, and one end of the transmission shaft 32 is connected with the speed reducer 36 through the clutch 35, and the speed reducer 36 is connected with the manual hand wheel 39. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com