Current collector

A current collector and boot removal technology, which is applied in the field of current collectors, can solve the problems of electric shock, inability to remove boots, and dangers of operators, and achieve the effects of high operating safety, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

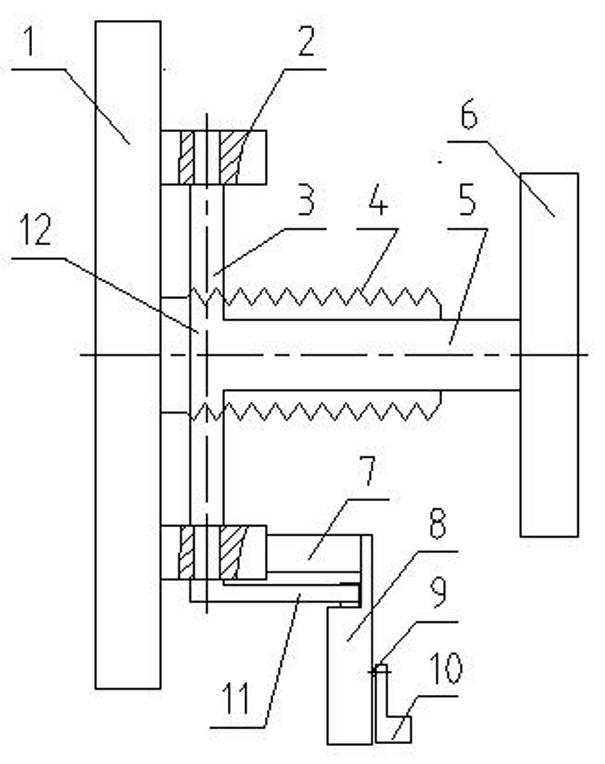

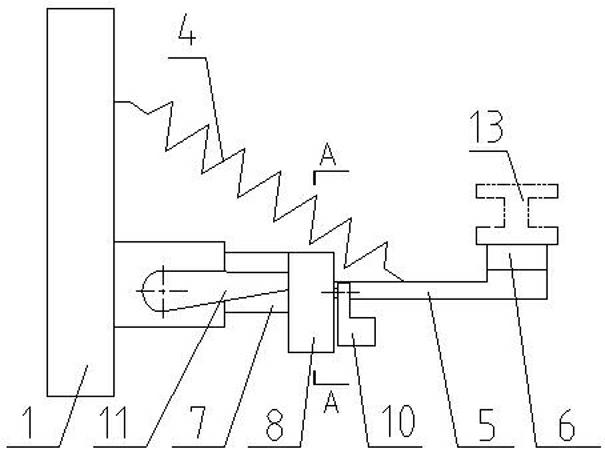

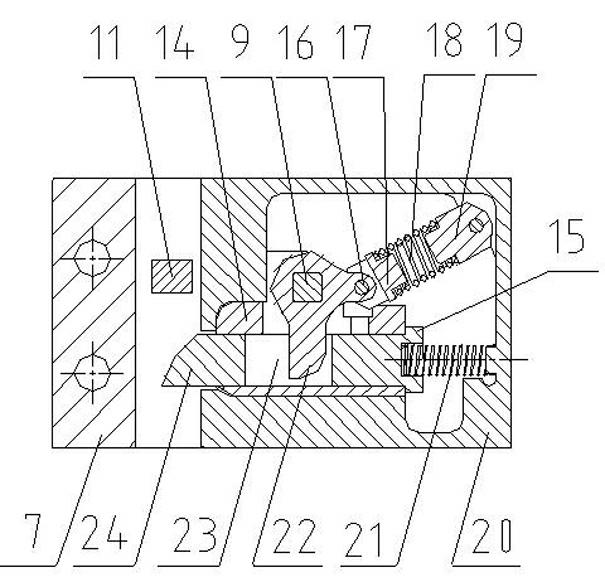

[0025] Including current receiver main body 1, swing lever mechanism 12, sliding shoe 6 and cables; said swing lever mechanism 12 includes swing lever rotating shaft 3 and its support 2, main spring 4, sliding shoe swing lever 5, shoe removal locking device 8 , Sliding shoe auxiliary rod 11; the sliding shoe swing rod 5 and the sliding shoe auxiliary rod 11 are parallel to each other, and are all perpendicular to the swing rod shaft 3; the shoe removal locking device 8 is installed on the flow receiving The main body 1 of the shoe, the tail of the auxiliary shoe lever 11 falls into the boot-off locking device 8; the boot-off locking device 8 includes a boot-off locking device casing 20, a deadbolt 24, a deadbolt spring 21, a shift fork Axis 9, shift fork 22; Dead bolt spring 21 is installed in dead bolt 24 afterbody; The tongue body of dead bolt 24 is provided with shift fork groove 23, and the head of shift fork 22 falls in shift fork groove 23; Shift fork 22 is installed in s...

Embodiment 2

[0027] On the basis of Embodiment 1, a deadbolt sliding seat 14 is installed between the deadbolt 24 and the housing 20 of the boot removal locking device. Installing the dead bolt sliding seat 14 is mainly from the considerations of technology, maintenance and production cost.

Embodiment 3-4

[0029] On the basis of Embodiment 1, the tail of the lock tongue 24 is provided with a limiting boss 15 to limit the protruding length of the lock tongue 24 .

[0030] Working principle, take embodiment 1 as an example to illustrate:

[0031] (1) Take off the boots: If an insulating rope is used to pull the sliding boot swing lever 5, the boots off 6 are separated from the power supply rail 13, and the tail of the auxiliary lever 11 of the sliding boots rotates synchronously. Figure 3-4 Turn clockwise as shown, the head of the shift fork 22 falling into the shift fork groove 23 pushes against the inner wall of the shift fork groove 23 near the dead bolt spring 21, forcing the dead bolt 24 to compress the dead bolt spring 21, and the head of the dead bolt 24 After the part retracts and enters the casing 20 of the boot-off locking device, the tail portion of the auxiliary shoe lever 11 continues to rotate to the bottom of the lock tongue 24, and then the fork control lever 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com