Device for ventilating and aerating a fuel tank

A fuel tank, connected technology, applied in the field of ventilation and ventilation devices, can solve problems such as destruction, freezing, valve damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

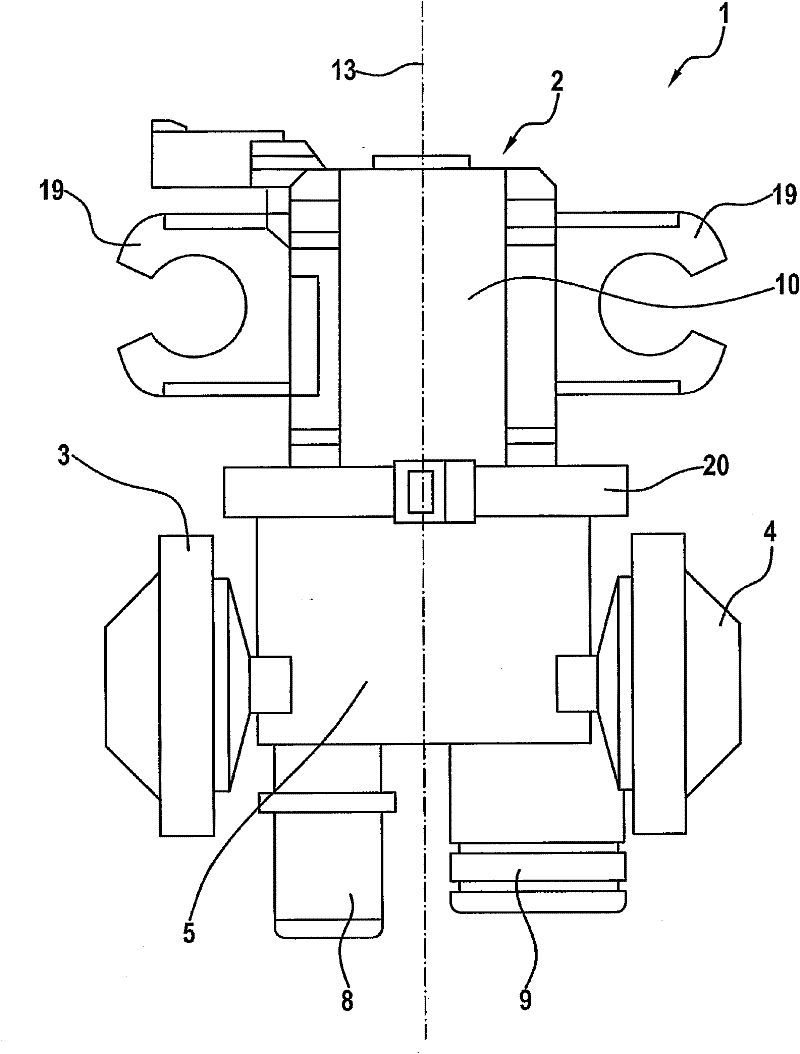

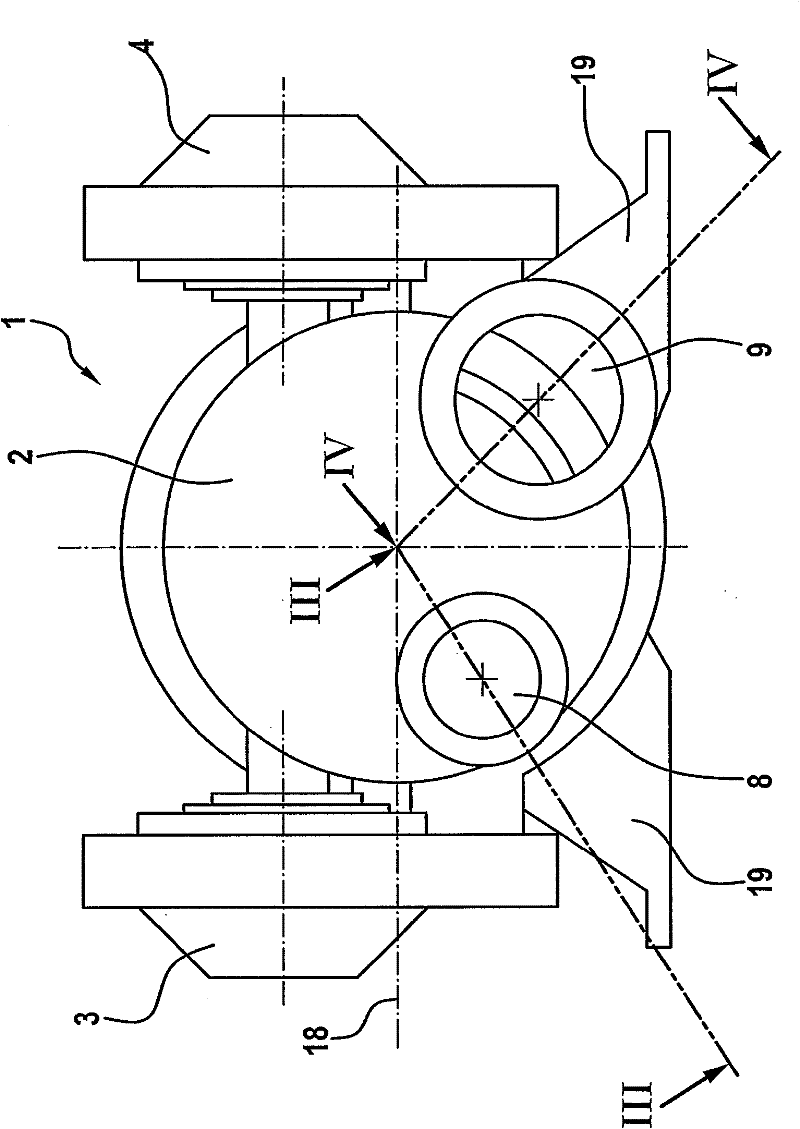

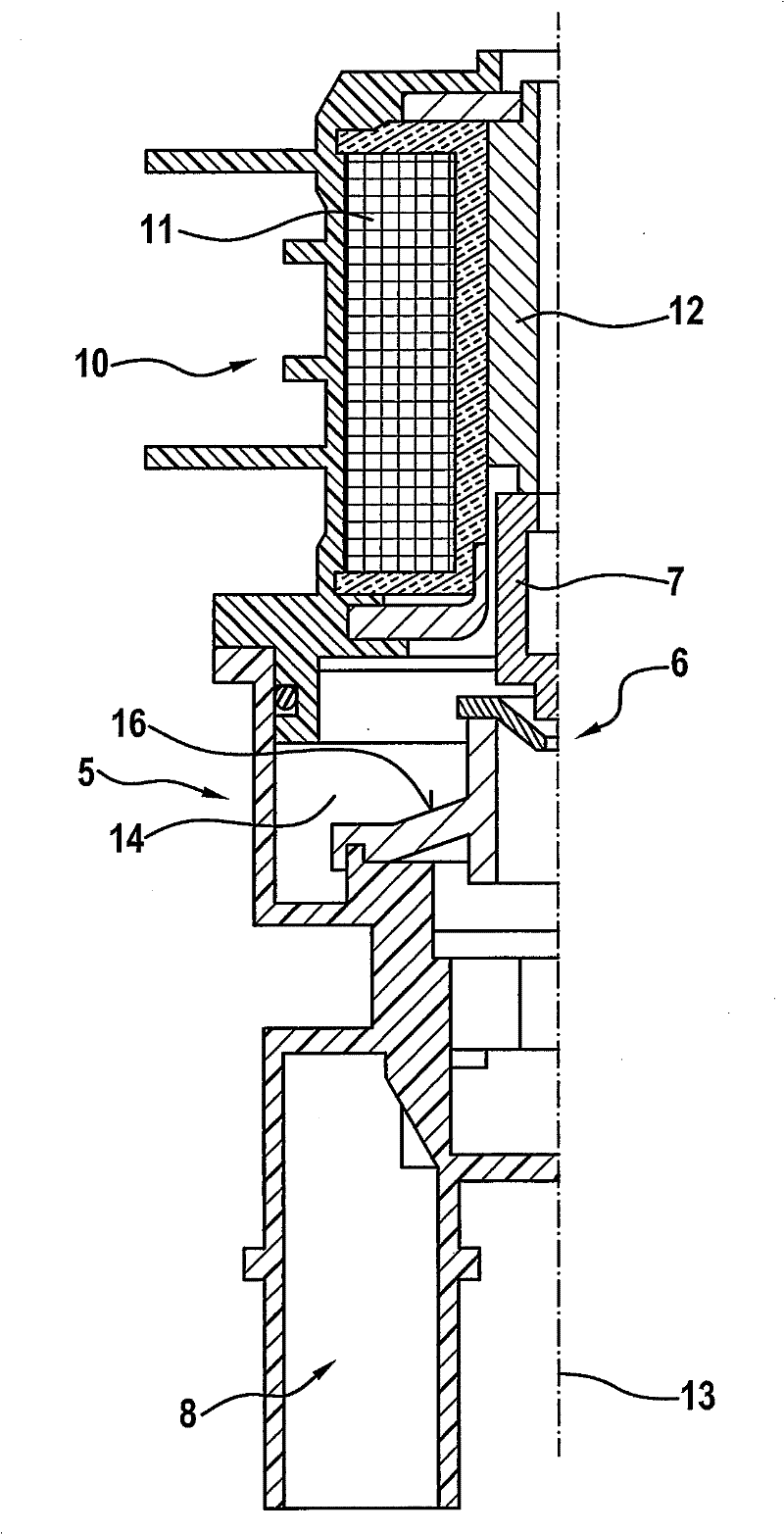

[0069] Figures 1 to 4 The valve unit 1 shown in is used for ventilation and ventilation of a fuel tank (not shown) and is intended to be installed between the fuel tank and an activated carbon filter (not shown) Prevent volatile hydrocarbons from being released into the atmosphere or environment during ventilation and ventilation.

[0070] The valve unit 1 basically consists of a tank shut-off valve 2 and two tank pressure regulating valves 3 , 4 spaced apart from each other and arranged on opposite (both) sides of the tank shut-off valve 2 .

[0071] The fuel tank shut-off valve 2 is a solenoid valve comprising two parts connected to each other in a rotatable manner, namely a valve part 5 and a valve actuating part 10, said valve part 5 having a valve seat 6 movable relative to the valve seat 6 valve element 7 and two connections 8, 9, namely a fuel tank connection 8 that can be connected to a fuel tank and a filter connection 9 that can be connected to an activated carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com