Multi-color injection molding machine

A two-color injection molding machine and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of complex positioning structure of rack and pinion, large gap between rack and pinion, and large load of pinion, etc., to achieve convenient processing and manufacturing, The effect of improving reliability and strengthening carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

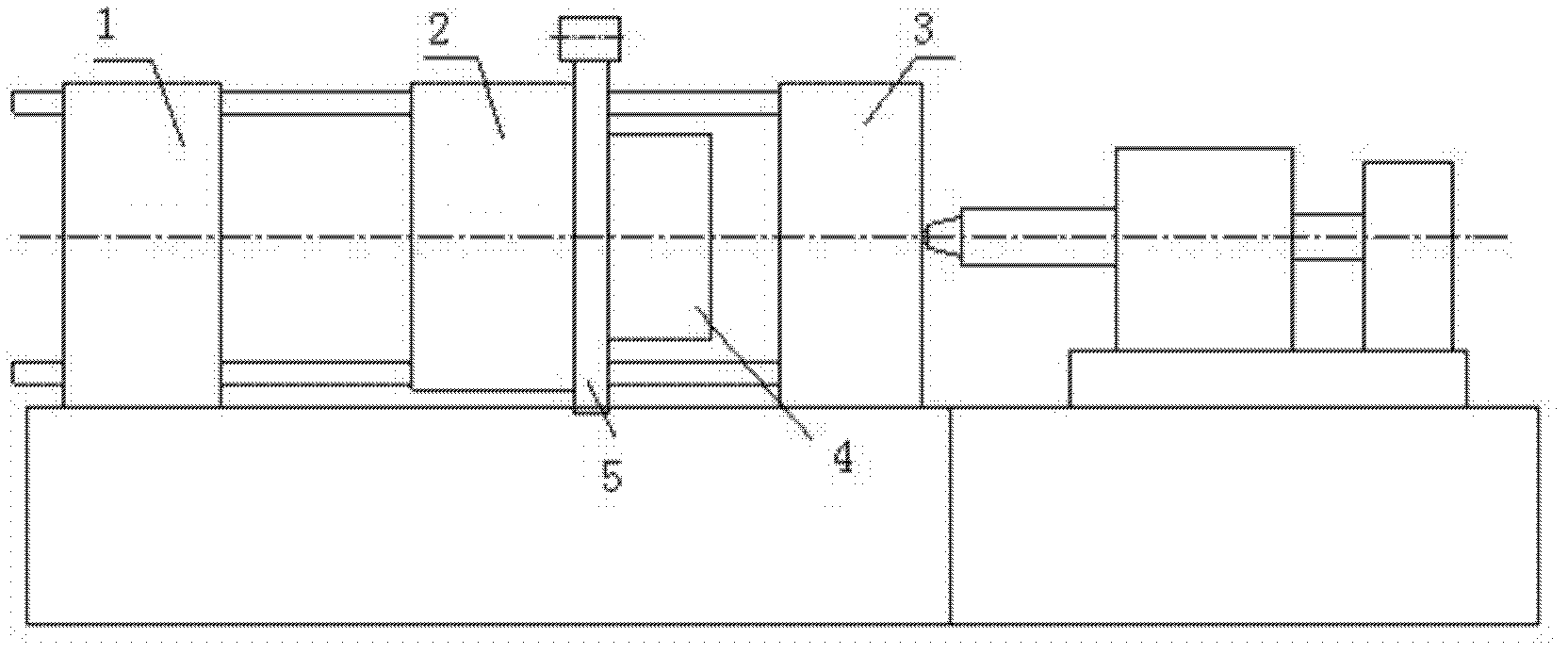

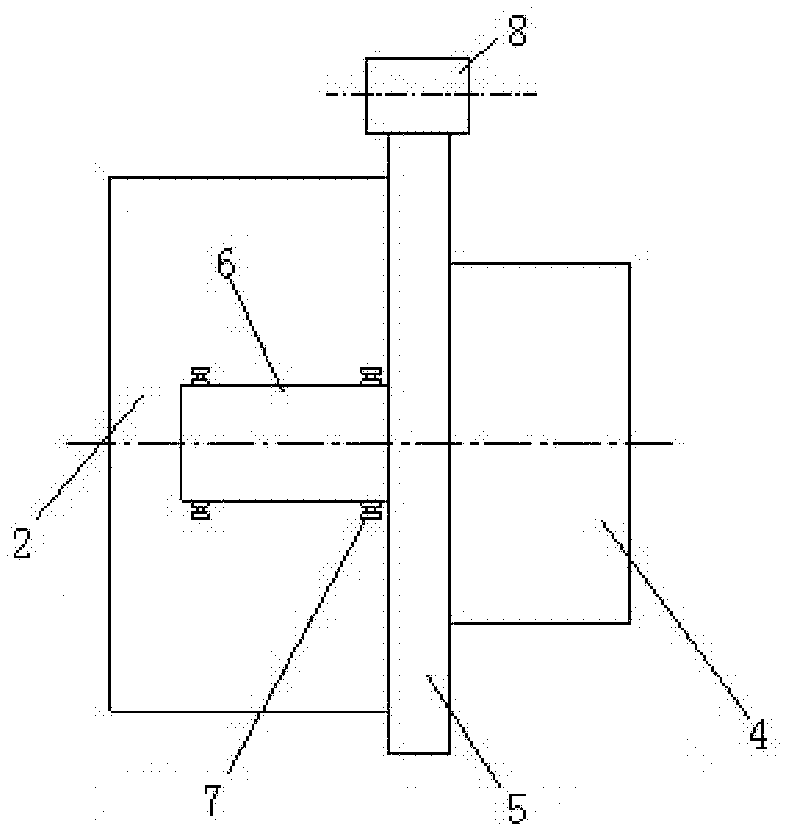

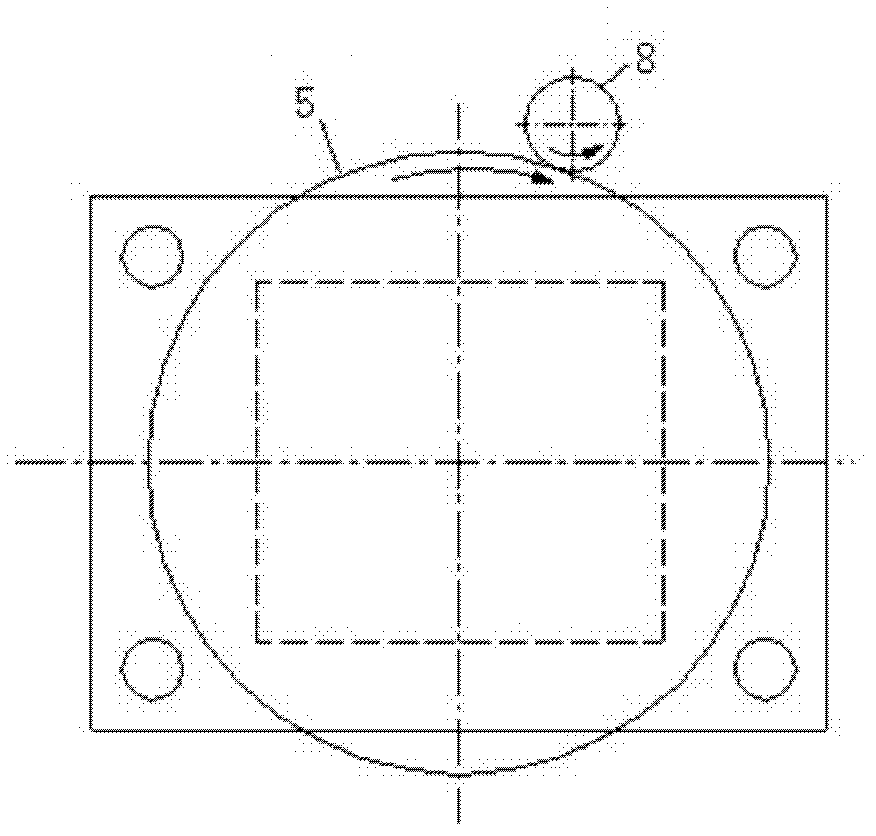

[0021] Such as figure 1 , figure 2 and image 3 As shown, a multi-color injection molding machine according to the present invention includes an adjusting platen 1, a movable platen 2 and a fixed platen 3, a mold 4 and a turntable 5 are fixedly arranged on the movable platen 2, and the turntable 5 passes through a rotating shaft 6 It is connected with the bearing 7 on the moving template 2, and the driving part 8 and the turntable 5 cooperate to rotate; the outer edge of the turntable 5 is toothed; the multi-color injection molding machine includes a two-color injection molding machine, a three-color injection molding machine and Four-color injection molding machine; the driving part 8 is a driving gear or a toothed pulley; the driving part 8 can rotate clockwise or counterclockwise. In the present invention, the entire turntable is designed as a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com