Rubber sleeve clamp

A fixture and rubber sleeve technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of inconvenient use of rubber sleeve fixtures and low work efficiency, and achieve the effect of solving single assembled products, improving quality and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

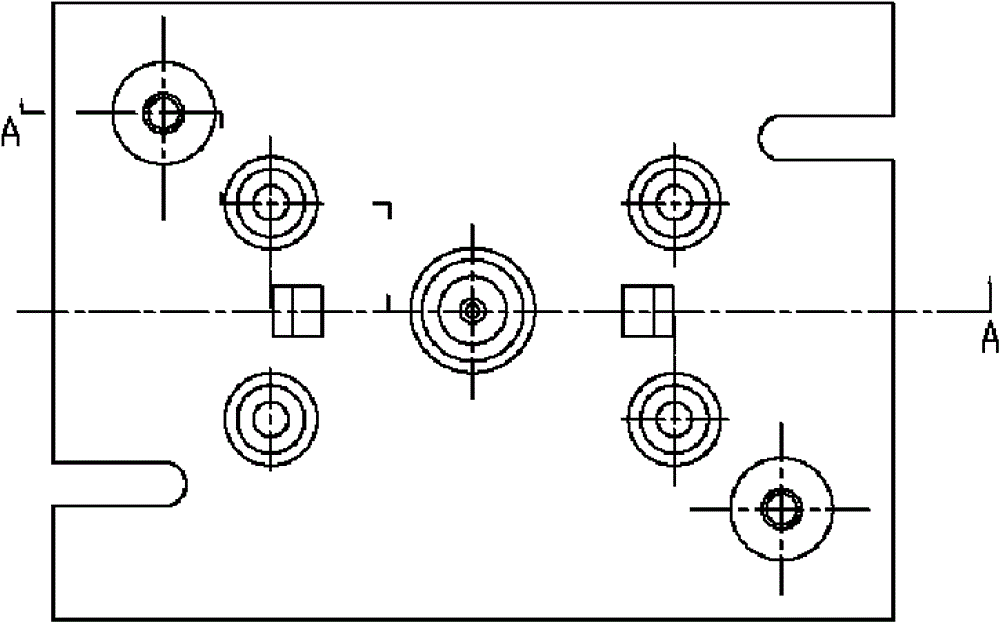

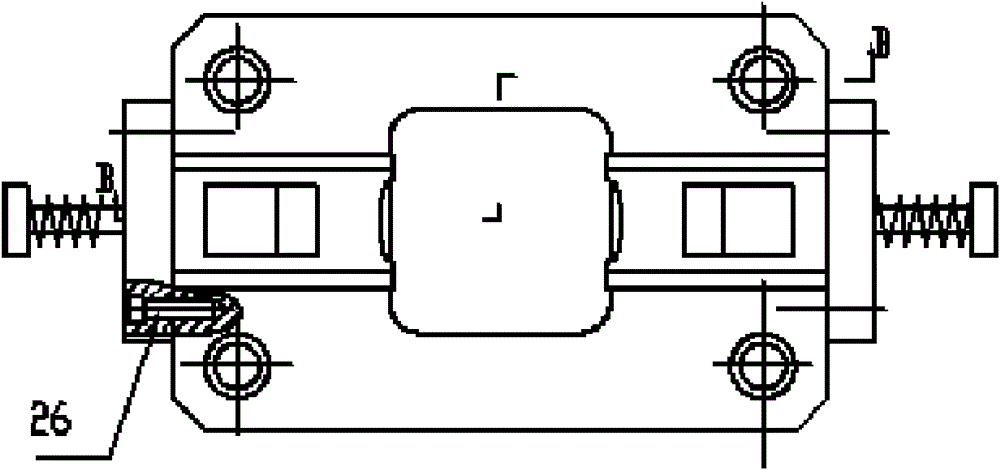

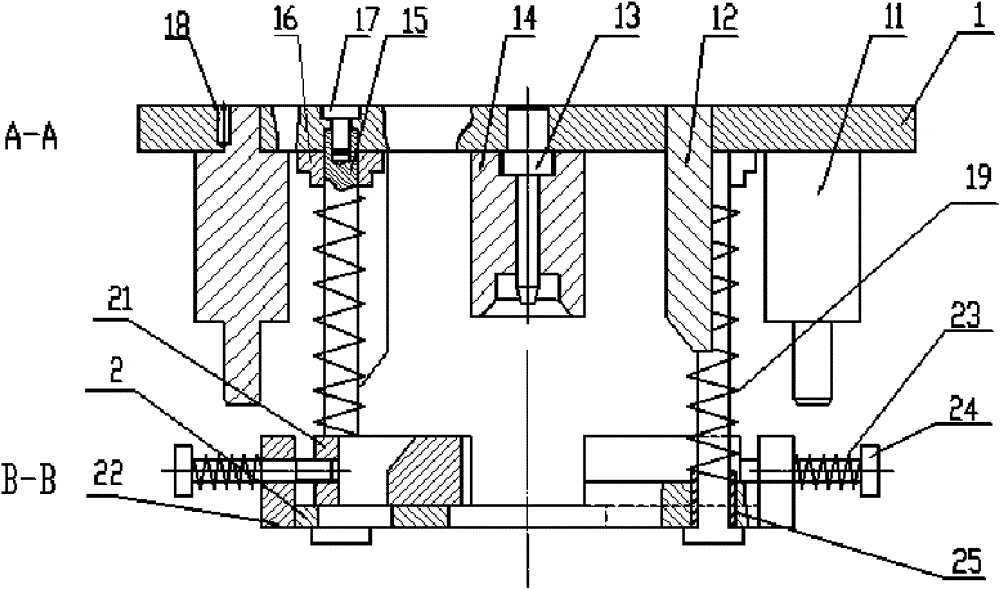

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a rubber sleeve clamp, which includes a longitudinal extruding device, a transverse extruding device and a base.

[0029] Wherein, the longitudinal extrusion device includes a set of elastic guide columns 15 installed on the upper plate 1 and plays a guiding role, a set of inclined sliding blocks 12 and a pressing block 14 . The pressing block 14 has a built-in ejector pin 13 with a tapered bottom. In order to restore the initial unextruded state of the lateral extruding device, several first compression springs 19 are wrapped around the elastic guide column 15 of the middle plate 2 .

[0030] The transverse extrusion device includes a set of perforations through which the two elastic guide columns 15 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com