Method for preventing deformation of large-size thin-wall annular casting during welding process

A technology of welding process and thin-walled rings, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high dimensional tolerance requirements, large diameter span, and excessive repair costs, so as to improve production efficiency, reduce welding stress, reduce The effect of small heat concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

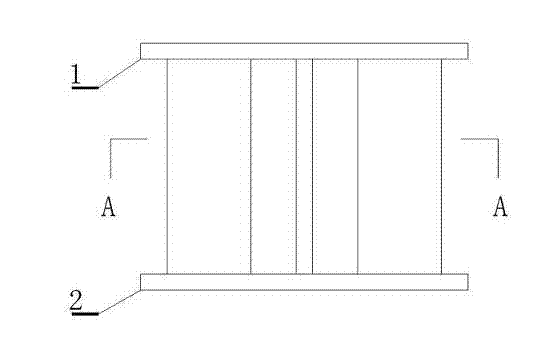

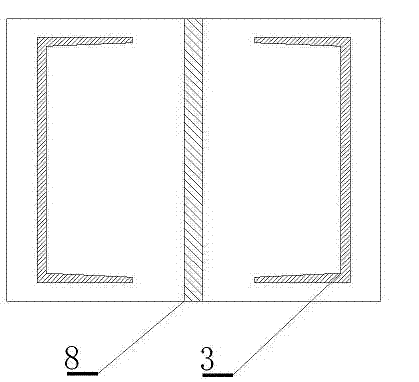

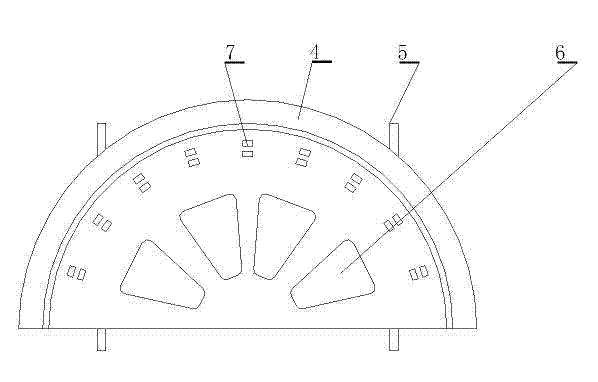

[0024] A method for preventing deformation during welding of large-size thin-walled ring castings is characterized in that the method includes the following steps:

[0025] a. Preparation before welding: Make a tool that supports the casting at least five points, ensures that the casting is flat when welding, and is not subject to external force to produce deformation pad iron and anti-deformation welding, and then fix the casting on the tool ;

[0026] b. Preheating before welding: preheat the welding area to 100~200℃ through the natural gas preheating pipe before welding;

[0027] c. Selection of welding process parameters: manual welding, low carbon steel electrode E5015-G (GB / T5118-”1995) with diameters of 4.0mm and 5.0mm, welding current controlled at 160~220A, voltage controlled at 15~30V, The length of the single-pass weld is controlled between 80 and 120mm, and the welding is symmetrical and segmented to minimize local heat concentration;

[0028] d. Welding process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com