Straight-pull cold-rolling mill tension control method based on speed feedforward

A technology of tension control and feedforward control, applied in the direction of tension/pressure control, etc., can solve the problems that cannot be satisfied at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

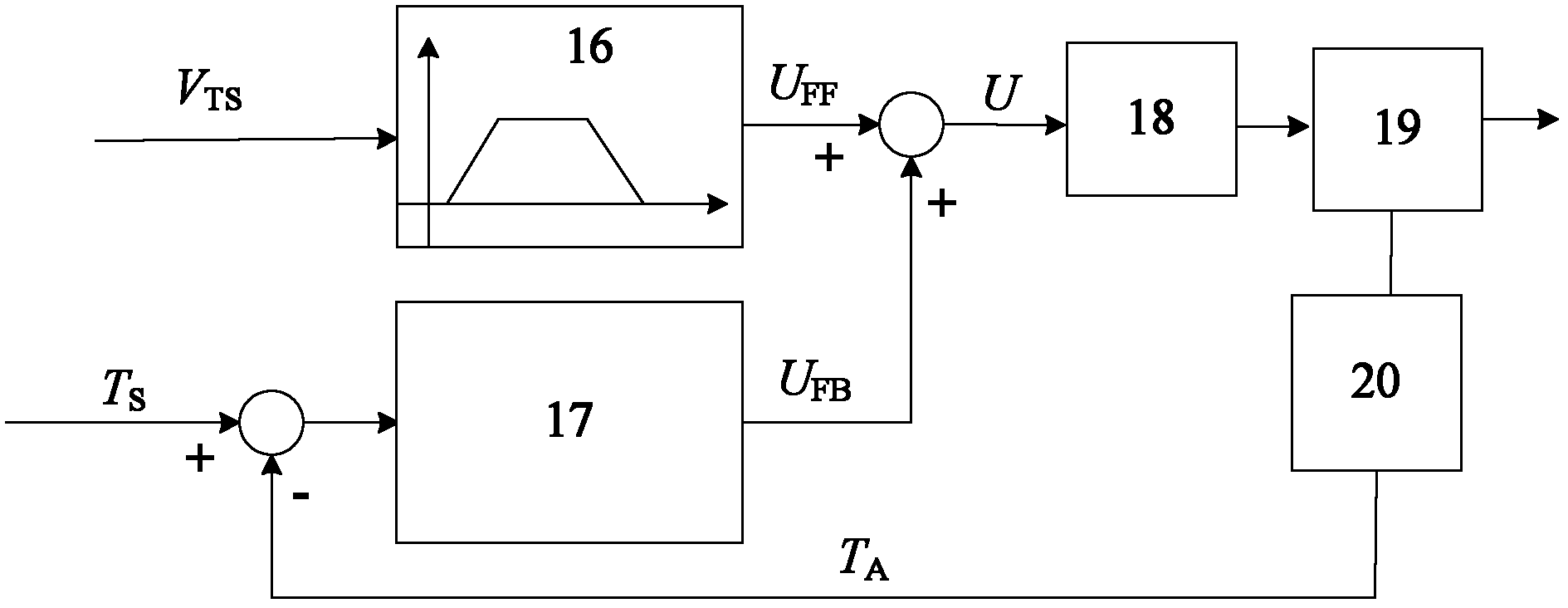

Method used

Image

Examples

Embodiment 1

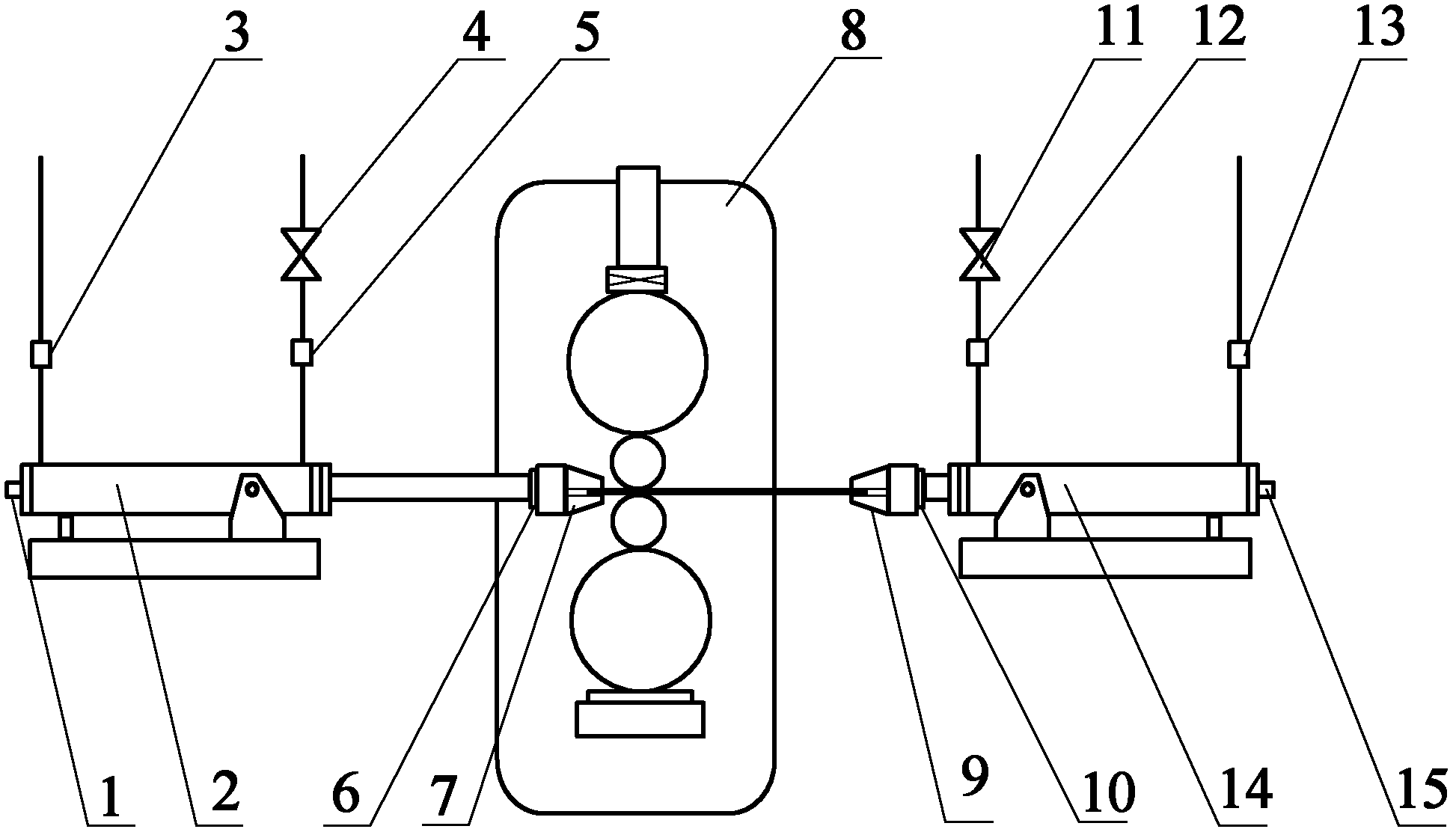

[0145] A 450mm straight-pull reversible cold-rolling experimental rolling mill in a technical center is adopted. The relevant parameters of the system are as follows:

[0146] Tension hydraulic cylinder inner diameter: 125mm, rod diameter: 90mm, maximum stroke: 2100mm, maximum tension: 100kN, maximum speed: 0.4m / s, tension hydraulic cylinder built-in displacement sensor model: RHM2150MD701S1G2100, high pressure oil source pressure: 23.5MPa, high pressure Model of oil pressure sensor: HDA3844-A-250-000; MOOG servo valve is used for flow control, model: D661-4444C G60JOAA6VSX2HA. The tension control system adopts Siemens S7400PLC, the CPU unit used is CPU416-2DP+FM458-1DP, and the tension controller runs in FM458-1DP.

[0147] Raw material specifications: thickness 3.05mm, width 310mm, length 600mm, variety SPCC,

[0148] Target thickness: 0.5mm,

[0149] Rolling passes: 7,

[0150] Maximum rolling speed: 0.25m / s.

[0151] Taking the seventh rolling pass as an example, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com