Dust-removing machine for paint spraying room

A technology for dust collectors and spray booths, applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, which can solve problems such as adhesion, reduced dust removal effect, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

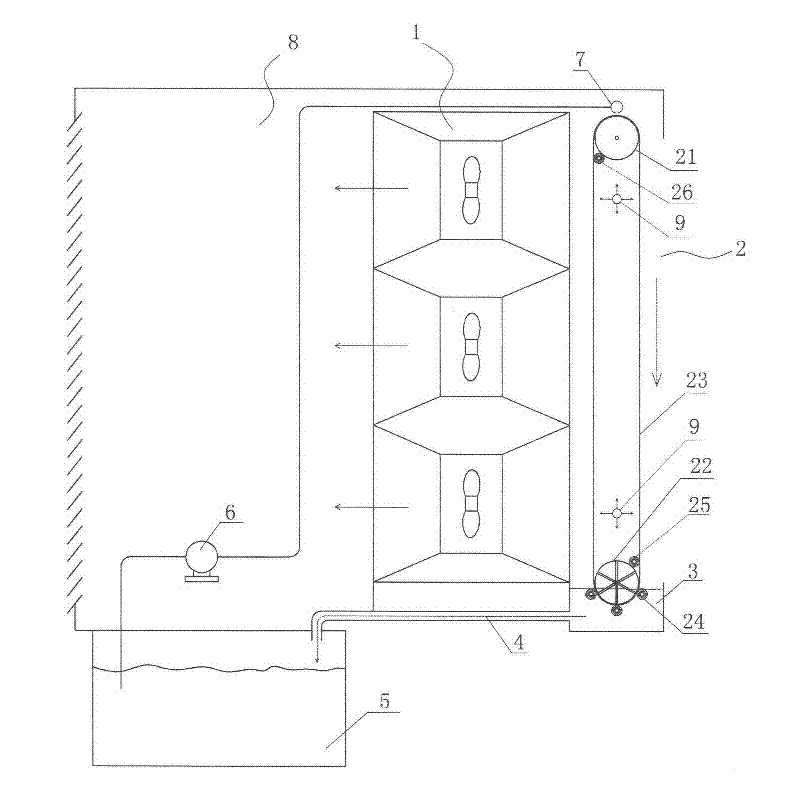

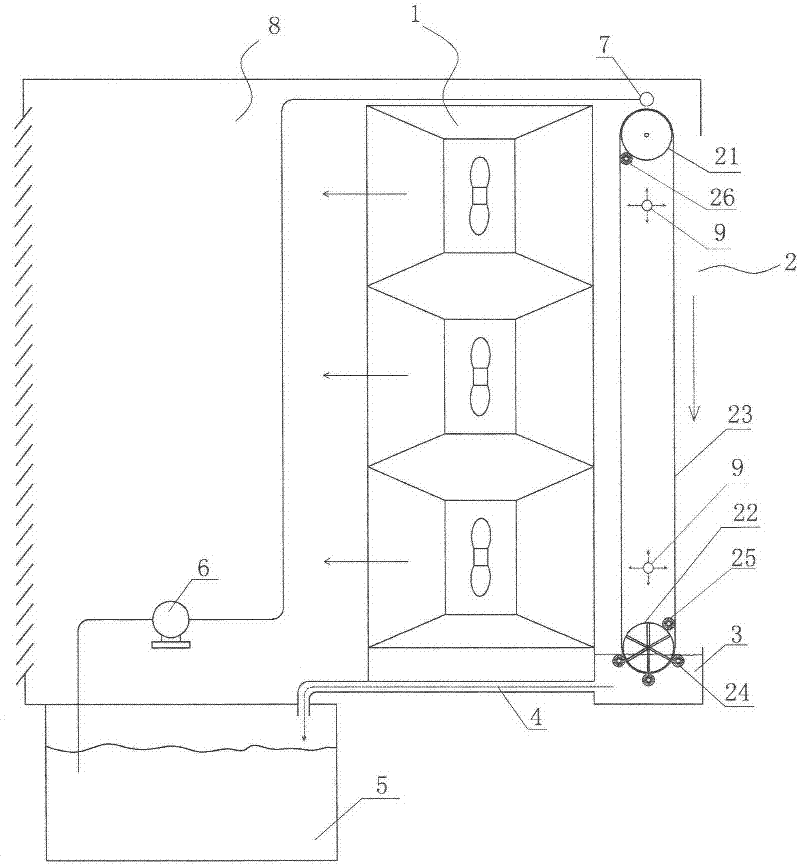

[0021] Such as figure 1 As shown, the dust collector used in the spray booth is mainly composed of suction and exhaust device 1, dust filter device 2, filter water tank 3, drain pipe 4, reservoir 5, circulating water pump 6, water delivery pipe 7, air purification device 8, spray The spray pipe 9 is composed of the dust filtering device 2 which is arranged above the filtering water tank 3 and includes an upper roller shaft 21, a lower roller shaft 22, a power device, a filter screen 23 sleeved on the upper roller shaft and the lower roller shaft, and In the dust removal device 24 in the filtered water tank 3, the spray water pipe 9 is installed in the space between the upper roller shaft 21 and the lower roller shaft 22. The spray water pipe 9 is connected with the water supply pipe 7 and the circulating water pump 6 provides unified water supply.

[0022] The lower roller shaft 22 is hollow and cylindrical, with more than one drain hole on the surface. The first cleaning shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com