Automatic stem pulling device

A rod pulling machine and automatic technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of wasting manpower, time-consuming and laborious, troublesome operation, etc., and achieve the effect of reducing labor intensity, convenient use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

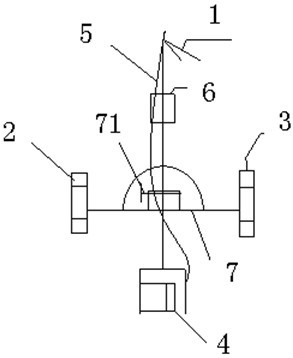

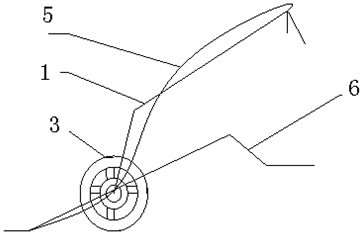

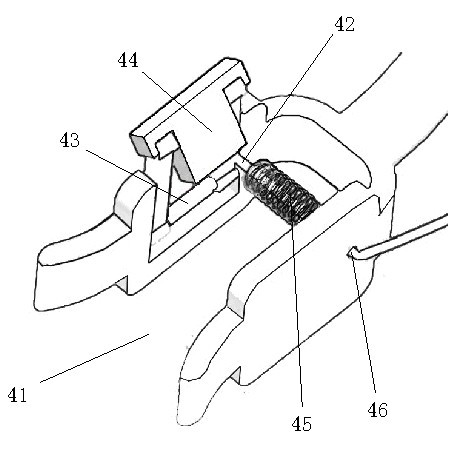

[0013] A kind of automatic rod puller device of the present invention, see figure 1 and figure 2 , the device comprises a handle 1, a left wheel 2, a right wheel 3, a clamping device 4, a hand brake system 5 and a pedal 6, and the left wheel 2 and the right wheel 3 are respectively arranged at two ends of a connecting shaft 7. The handle 1 is Y-shaped, and the split part at the front end is arranged on the connecting shaft 7 . Pedal 6 is as a lever structure form, and the middle part of pedal 6 is arranged on the connecting shaft 7 by rotating shaft 71. The clamping device 4 is arranged at the front end of the pedal 6 and is located at the front side of the connecting shaft 7 . image 3 It is a structural schematic diagram of the clamping device in the present invention. The clamping device 4 includes a U-shaped groove 41, a connecting rod 42, a connecting rod shaft 43, a clamp block 44 and a spring 45, and the clamp block 44 is arranged in the U-shaped groove through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com