Preparation method of large thickness period polarization ferroelectric crystal material

A ferroelectric crystal, periodic polarization technology, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of mature and easy-to-implement bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

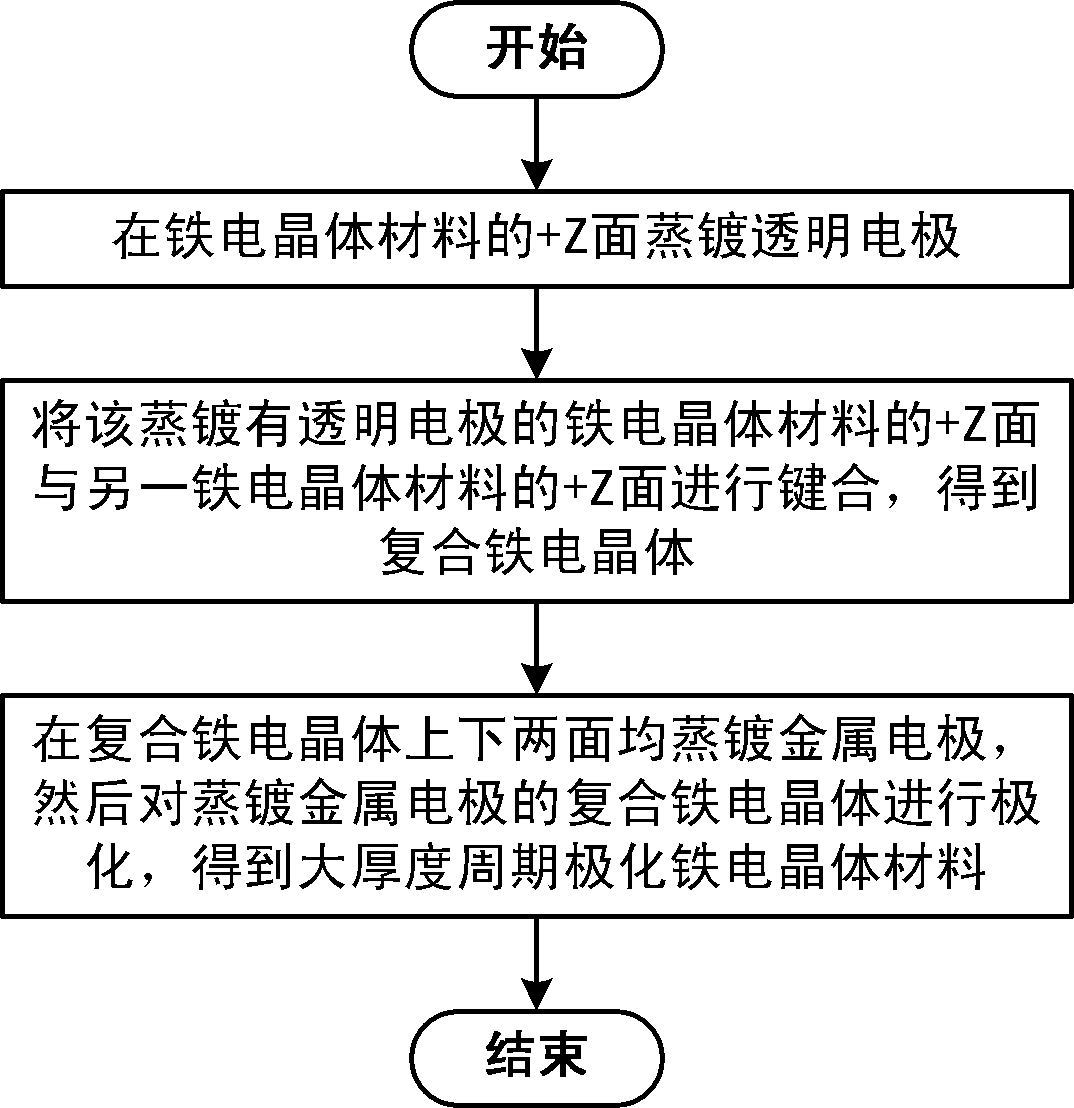

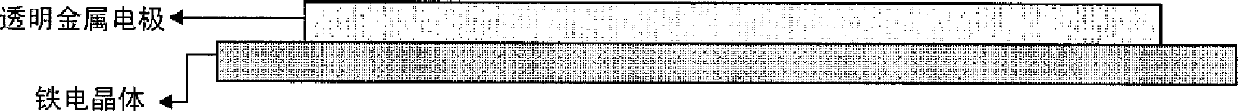

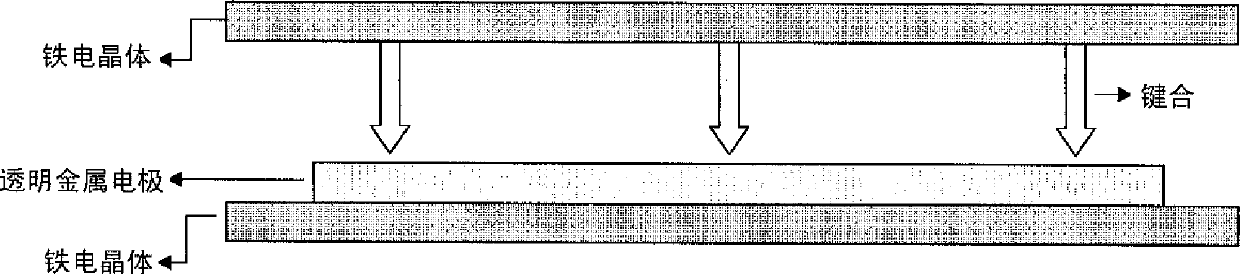

[0026] Such as figure 1 as shown, figure 1 It shows a flowchart of a method for preparing a large-thickness periodically poled ferroelectric crystal material according to an embodiment of the present invention. The method includes: vapor-depositing a transparent electrode on the +z surface of the ferroelectric crystal material; The +z surface of the ferroelectric crystal material is bonded with the +z surface of another ferroelectric crystal material to obtain a composite ferroelectric crystal; metal electrodes are evaporated on the upper and lower surfaces of the composite ferroelectric crystal, and then the evaporated metal electrodes are The composite ferroelectric crystal is polarized to obtain a large-thickness peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com