Adjustable clamp for testing battery and mounting method thereof

A battery and battery technology to be tested, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of lack of detection ability, limited adjustment range, easy to loose, etc., to improve rigidity, easy operation, and easy installation. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

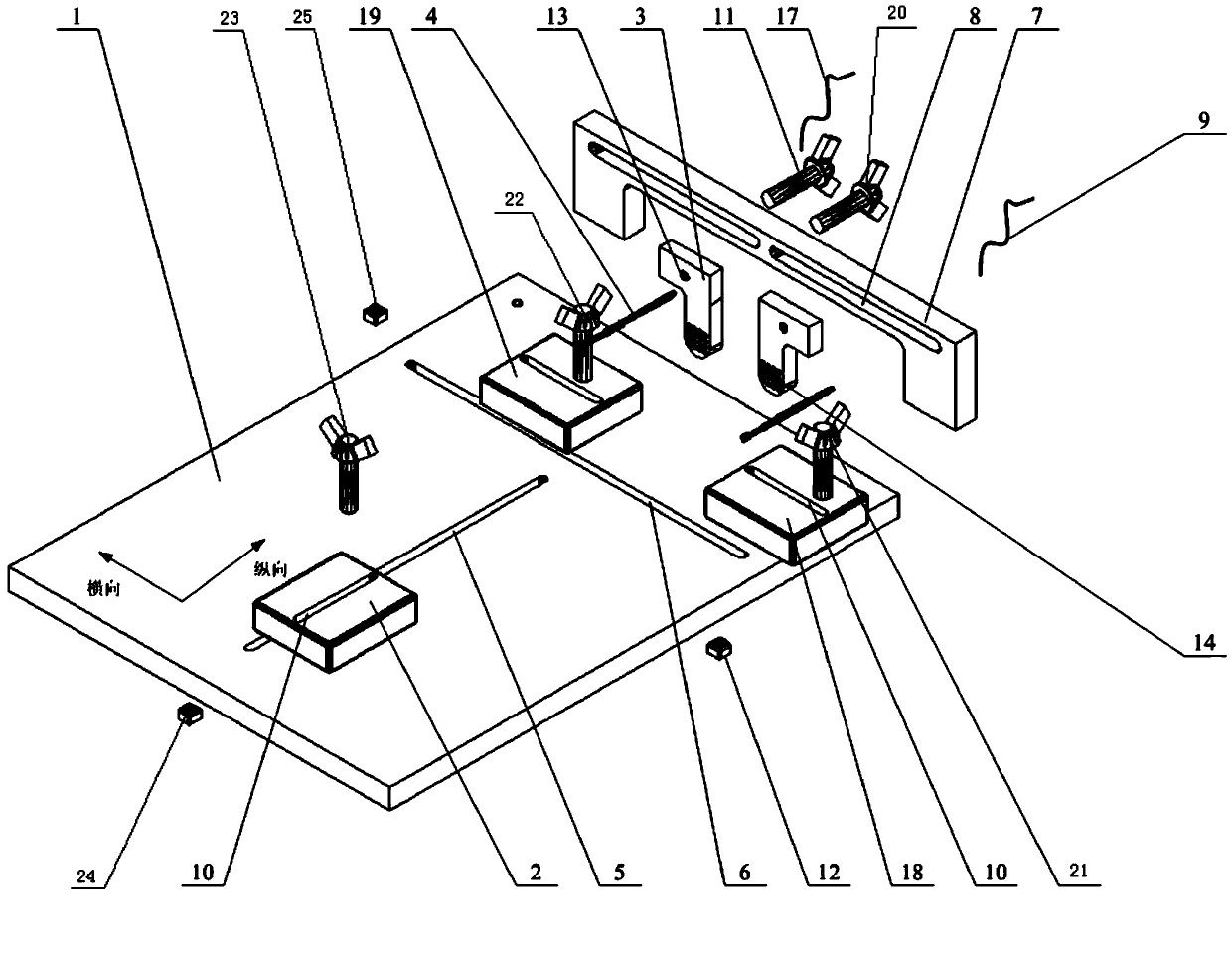

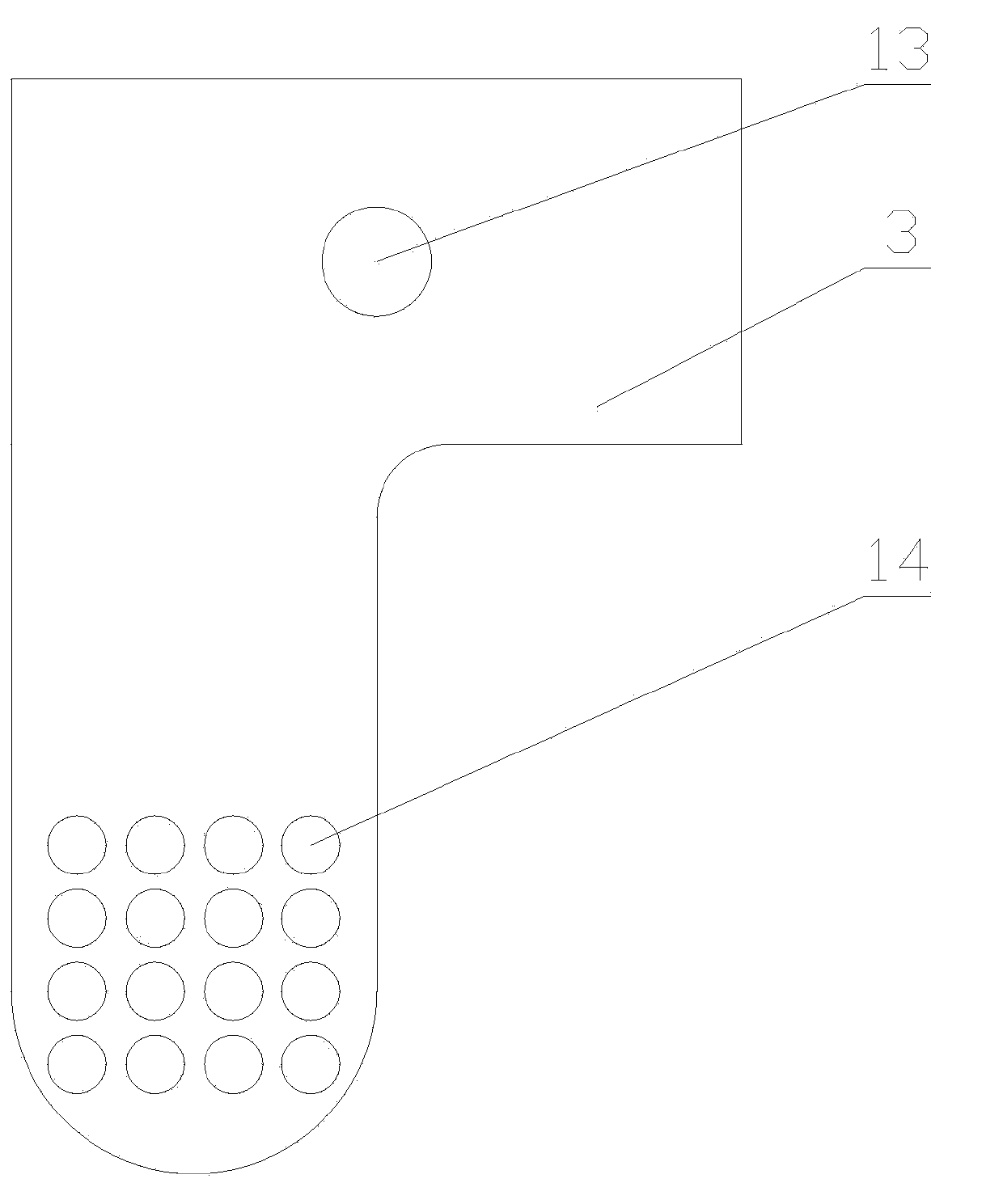

[0045] Such as Figure 4 As shown, the battery 15 to be tested has an irregular shape. First, the battery 15 to be tested is placed on the base 1, and the electrodes 16 on it are placed in the direction of the main bracket 7, and then the third threaded knob 21 is rotated to loosen the arrangement. On the guide groove b6, the second clamping block 18 and the third clamping block 19, in the guide groove b6, adjust the position of the second clamping block 18 and the third clamping block 19, and pass the second clamping block 18 Adjust the relative position of the second clamping block 18 and the third clamping block 19 with the guide groove d10 on the third clamping block 19, and rotate and adjust the angle of the second clamping block 18 and the third clamping block 19, so that Fit the battery 15 to be tested, and after adjustment, fasten the second clamping block 18 and the third clamping block 19 on the guide groove b6 through the third threaded knob 21 and the fourth thread...

Embodiment 2

[0047] Such as Figure 5 As shown, the battery to be tested 15 has a rectangular structure. First, the battery to be tested 15 is placed on the base 1, and the electrode 16 on it is placed towards the direction of the main bracket 7, and then the third threaded knob 21 and the fourth threaded knob are passed. 22 Rotate and loosen the second clamping block 18 and the third clamping block 19 arranged on the guide groove b6, adjust the position of the second clamping block 18 and the third clamping block 19 in the guide groove b6, and pass the first The guide groove d10 on the second clamping block 18 and the third clamping block 19 adjusts the relative position of the second clamping block 18 and the third clamping block 19, and rotates and adjusts the second clamping block 18 and the third clamping block 19, so as to fit the battery under test 15, after adjustment, the second clamping block 18 and the third clamping block 19 are fastened on the guide groove b6 through the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com