Beef quality multi-parameter simultaneous detection method by multichannel near-infrared spectroscopy

A near-infrared spectroscopy and detection method technology is applied in the field of simultaneous detection of beef quality and multi-parameters with multi-channel near-infrared spectroscopy, achieving the effects of consistent distance, rich information and improved detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The specific method of the present invention will be further described below through the beef tenderness detection embodiment in conjunction with the accompanying drawings.

[0053] In August 2011, tenderloins from different cattle that were matured for 14 days after slaughter were purchased from a supermarket in Haidian District, Beijing, and transported to the non-destructive testing laboratory of agricultural and livestock products of China Agricultural University, without preparations such as cleaning, removing fat or connective tissue, and water bath Work, the meat sample is evenly divided into meat pieces with a thickness of 3cm, and a total of 40 samples are obtained after removing irregular meat pieces.

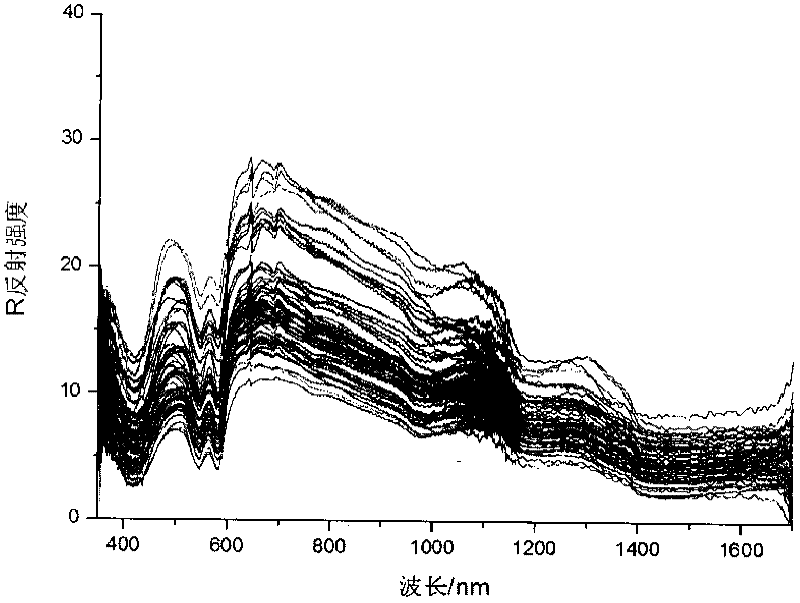

[0054] Immediately after numbering the specimens, use the detection system described (e.g. figure 1 shown) according to the method of the present invention, obtain the reflectance spectrum images of all samples (such as figure 2 shown).

[0055] After obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com