Transmission part for elevators

A technology for transmission parts and elevators, which is applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of wire rope and traction sheave wear, pollution of elevator shaft components, shortening of wire rope life, etc., to improve transmission performance, reduce Energy consumption, the effect of eliminating transition areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

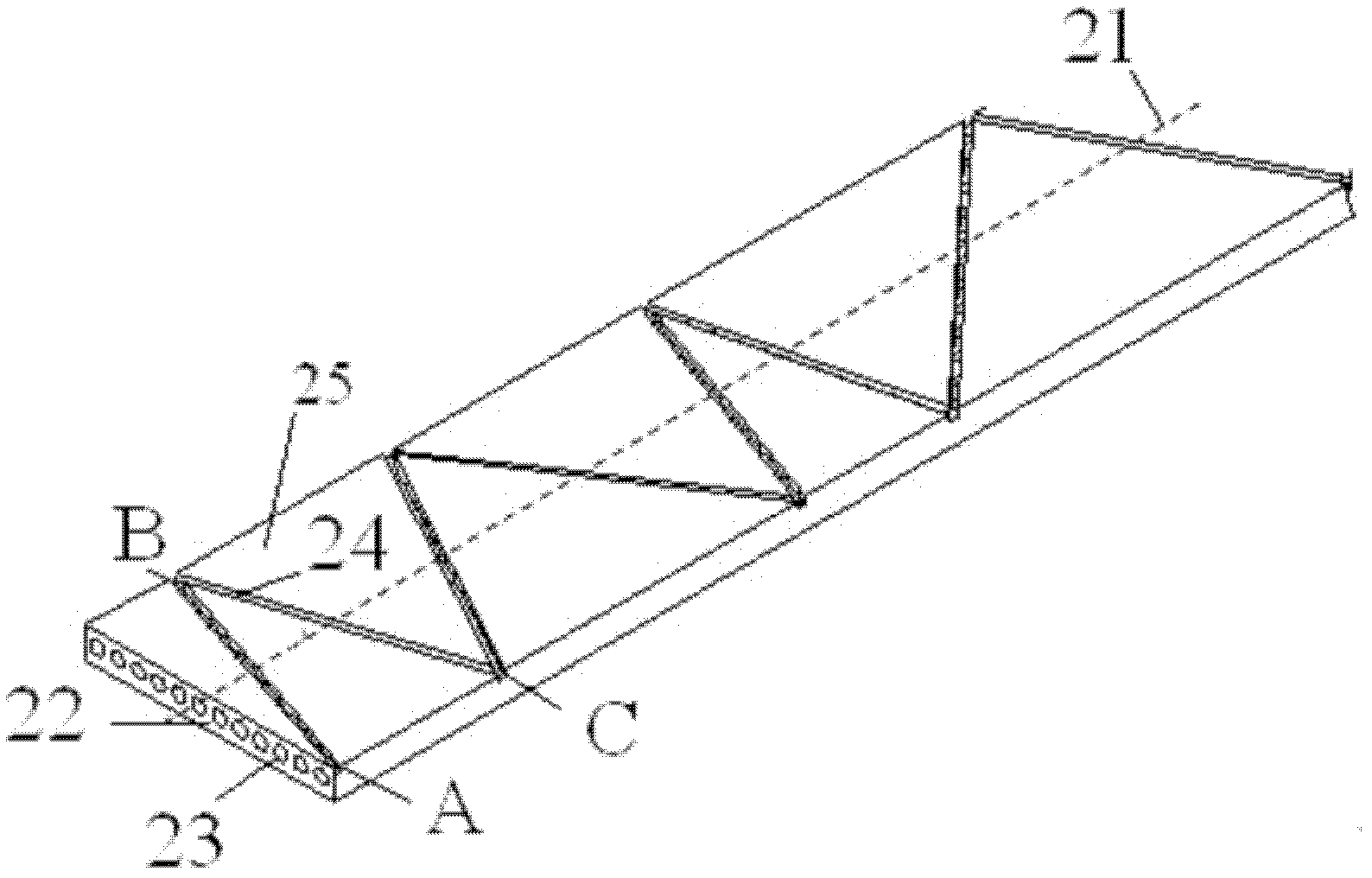

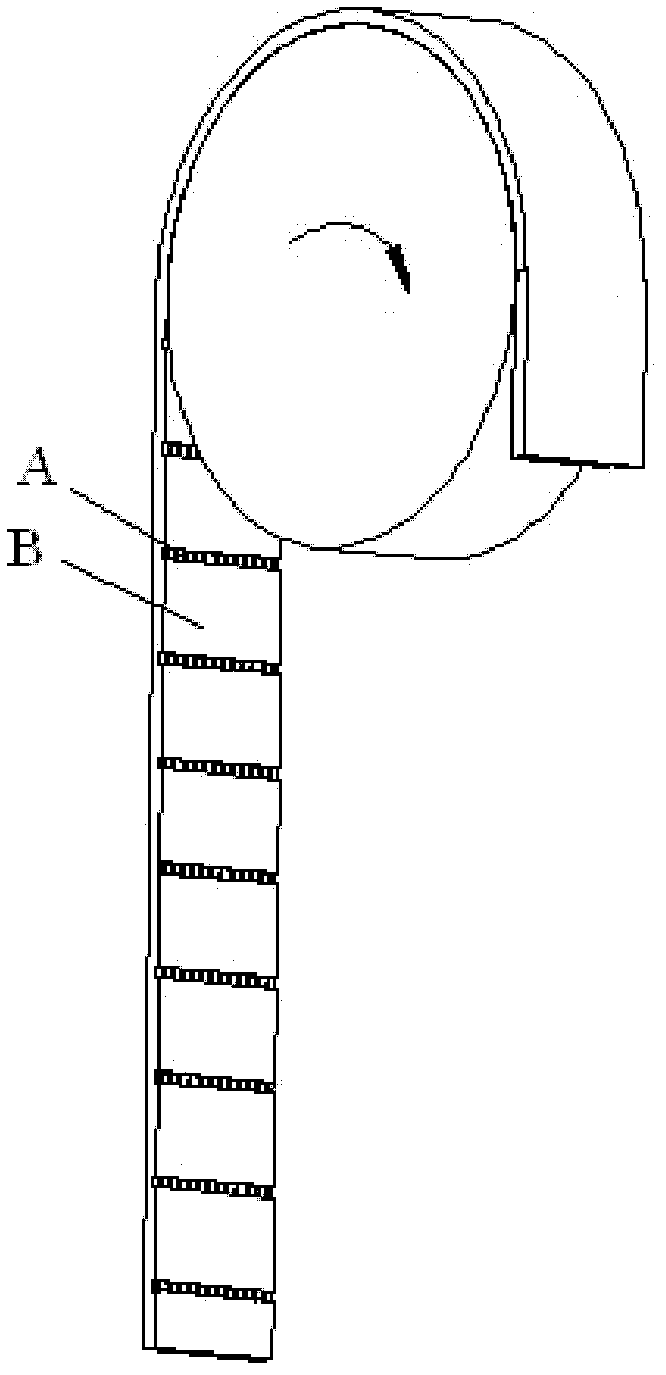

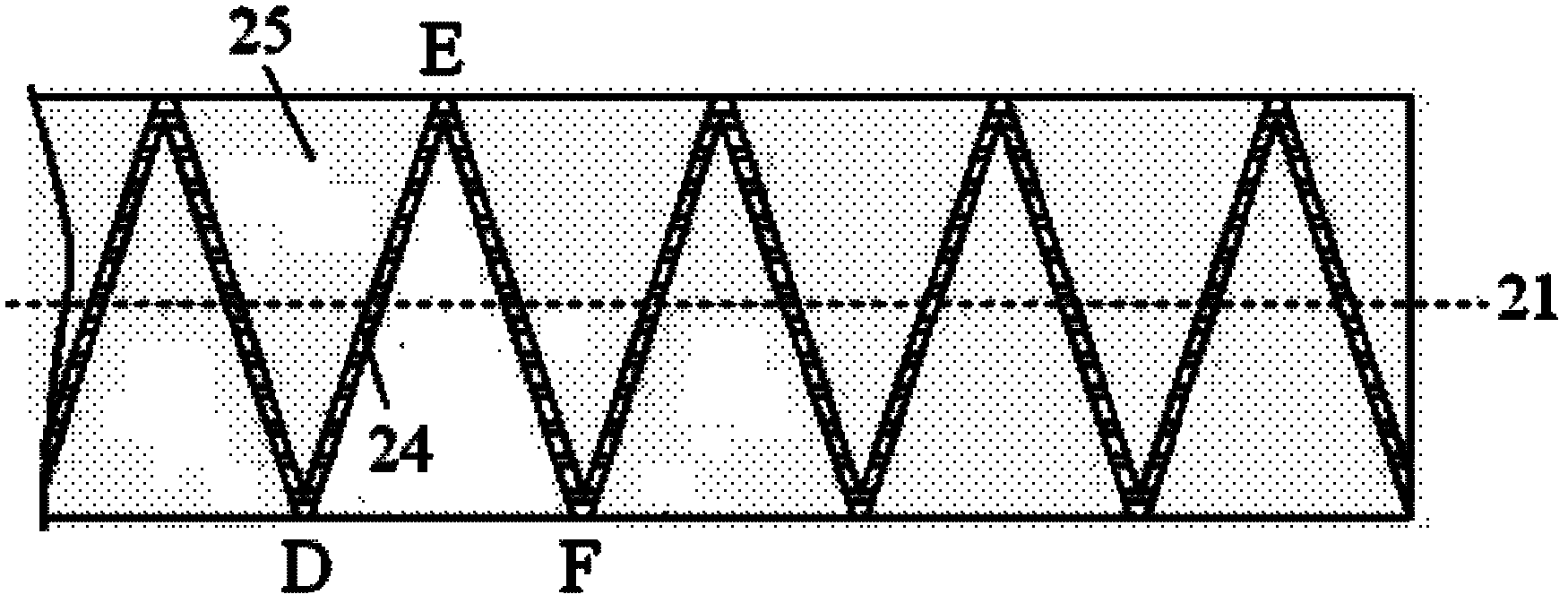

[0026] The applicant elaborates the specific implementation manner of the present invention in detail according to the accompanying drawings.

[0027] An elevator system consists of a car, a counterweight, a host system including traction sheaves and transmission components for dragging the car and counterweight. One end of the transmission part is connected to the car, and the other end is connected to the counterweight, and the energy transmission is realized through the traction sheave of the host system. The main engine system drives the transmission part to drive through the static friction force generated between the traction sheave and the transmission part, and the transmission part meshes with the pulley on the car or the counterweight to realize the up and down movement of the car and the counterweight. It can be seen that the transmission components for elevators are indispensable components in the operation of elevators, and the quality of transmission components c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com