Automobile electromechanical brake

A technology of mechanical brakes and automotive electronics, applied in brake actuators, slack regulators, etc., can solve the problems of slow braking response speed, difficult assembly and maintenance, easy leakage of hydraulic circuits, etc., to achieve good braking performance, easy Maintain and ensure the effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

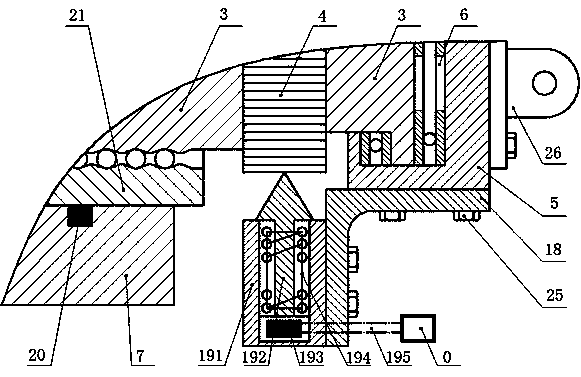

[0047] Such as figure 1 As shown, the automotive electromechanical brake of the present invention includes a front side floating caliper 1 and a floating caliper body 7. The front side floating caliper 1 is connected to the front friction plate 23 through a friction plate support frame 24, and the front end of the floating caliper body 7 is connected through a nut piston 21. The rear friction plate 22, the brake disc 2 is arranged between the front friction plate 23 and the rear friction plate 22;

[0048] The nut piston 21 is fixedly connected with the floating caliper body 7, the nut piston 21 cannot rotate relative to the floating caliper body 7, and can only move axially together with the floating caliper body 7;

[0049] A sealing ring 20 may be provided between the nut piston 21 and the floating caliper body 7; or the piston cylinder of the nut piston 21 is a square section; or the nut piston 21 is provided with a sliding rod for guiding;

[0050] The nut piston 21 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com