Roller retainer type overrun clutch for energy-saving and environmental-friendly loader

An overrunning clutch, energy-saving and environment-friendly technology, applied in the direction of clutches, one-way clutches, mechanical equipment, etc., can solve problems such as service life reduction, damage to overrunning clutches, transmission overrunning clutches that cannot adapt to large torque transmission, etc. Effects of increased strength and improved fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

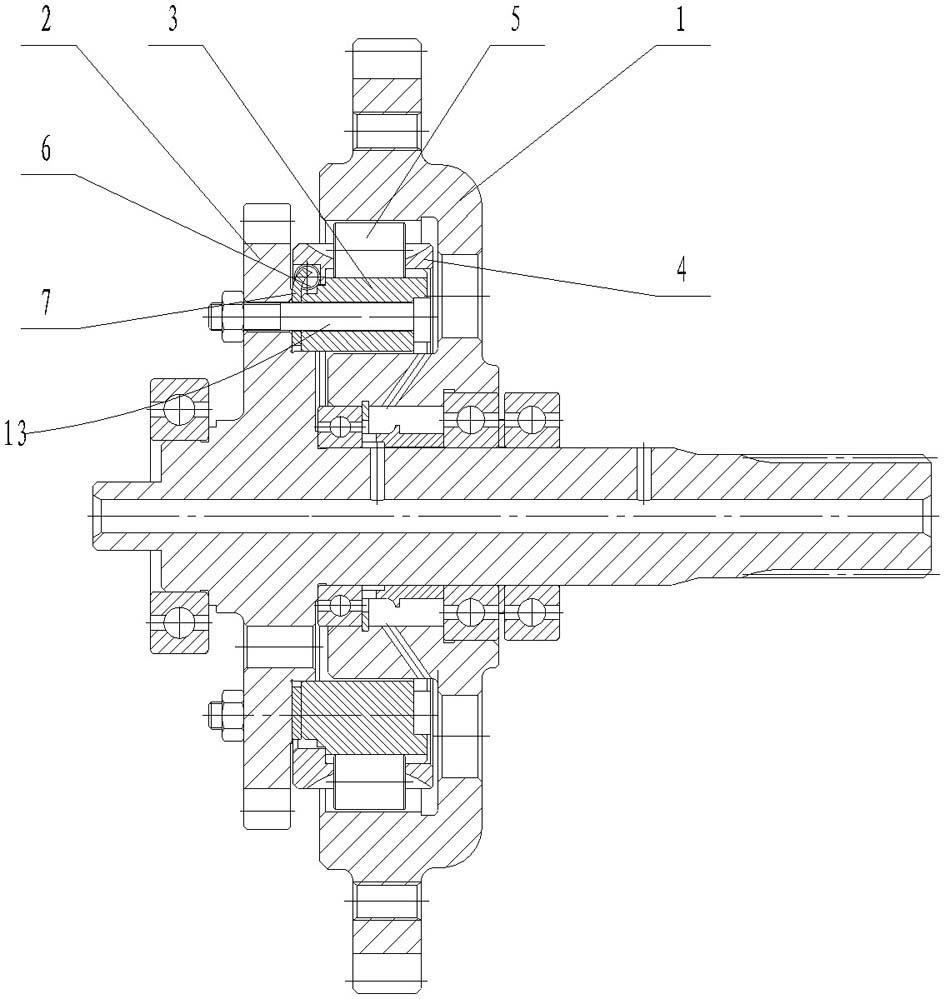

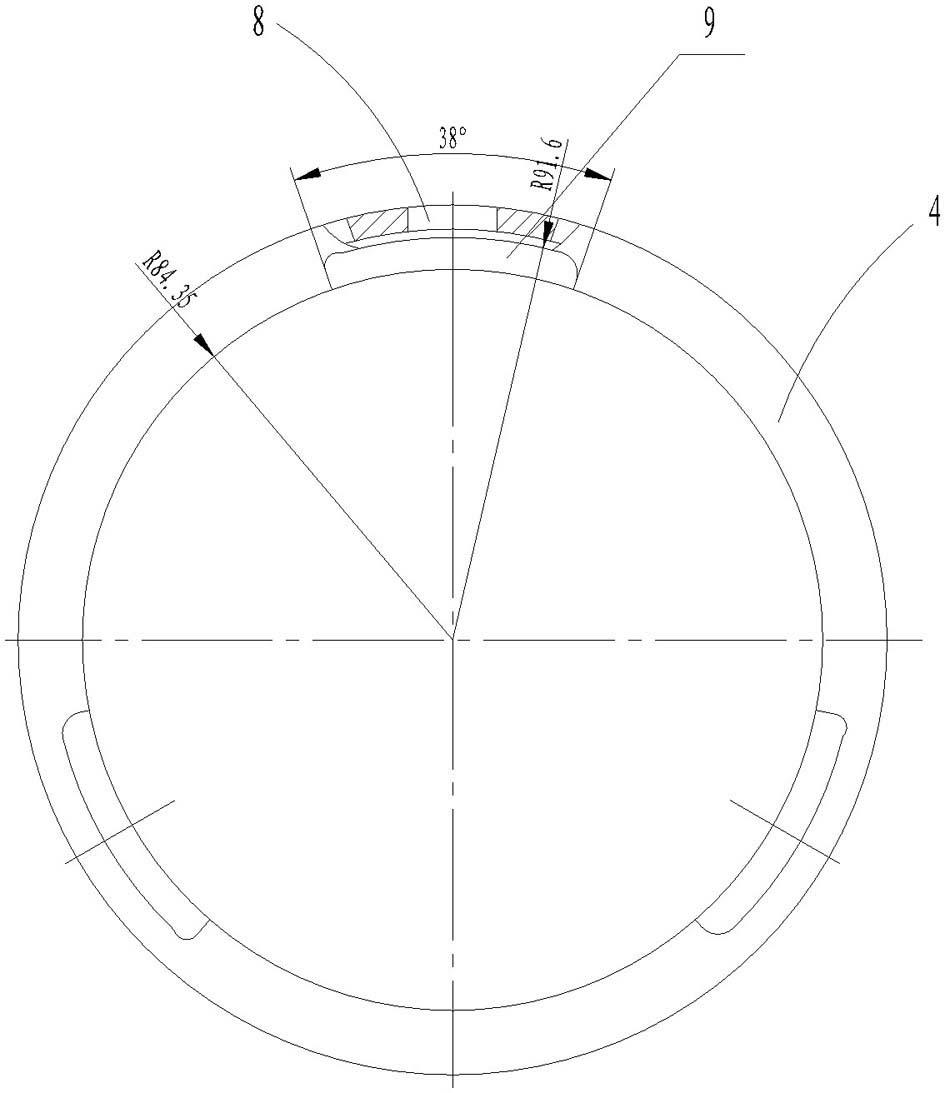

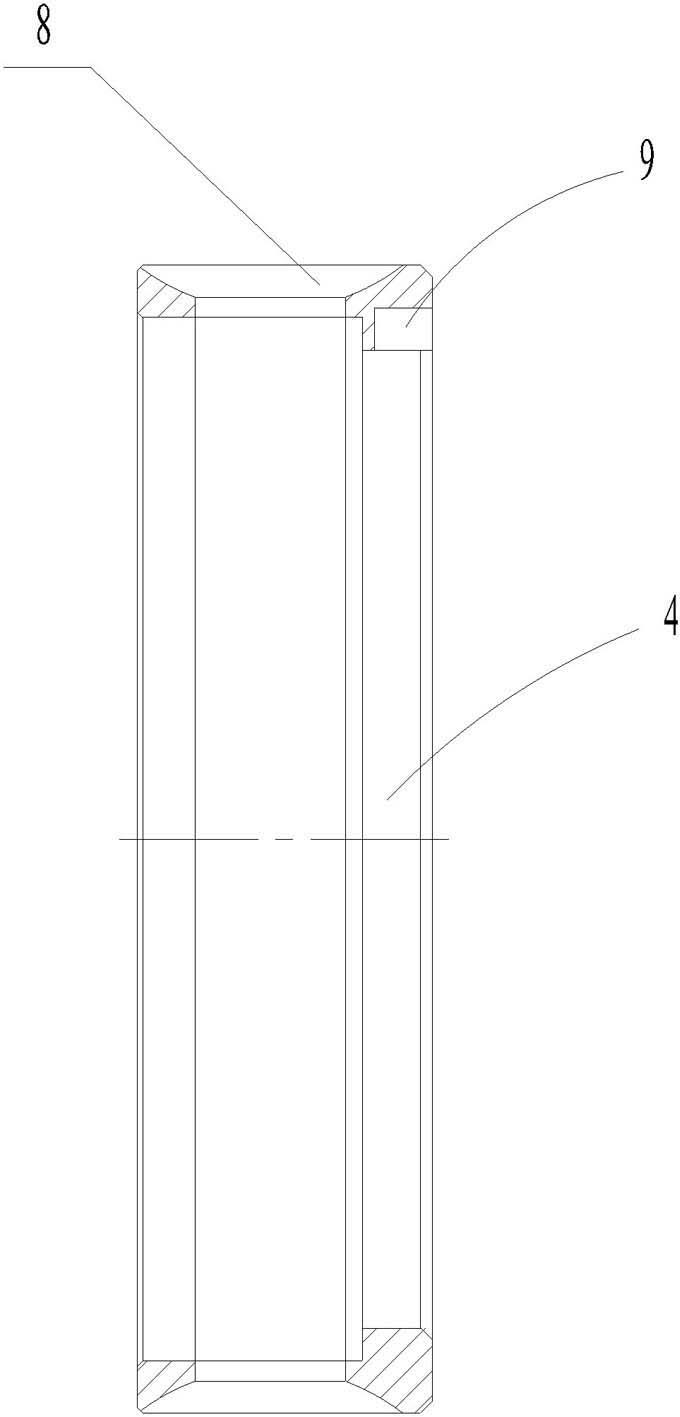

[0021] Example 1: Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, an energy-saving and environmentally friendly roller cage type overrunning clutch for loaders includes an outer ring gear 1, an intermediate input shaft 2, an inner ring cam 3, a roller cage 4 and a roller 5. The outer ring The gear 1 is provided with an intermediate input shaft 2, the intermediate input shaft 2 is provided with an inner ring cam 3, the inner ring cam 3 is provided with a roller cage 4, and the roller cage 4 is A roller groove 8 and a spring groove 9 are provided. The roller groove 8 is provided with a roller 5, the spring groove 9 is provided with a spring 6, and the roller 5 and the inner ring cam 3 work surface In contact with the outer ring gear raceway, a locking plate 7 is provided between one end surface of the intermediate input shaft 2 and one end surface of the inner ring cam 3, and the locking plate 7 is evenly provided with three locks along the circumfere...

Embodiment 2

[0023] Example 2: Such as figure 1 , figure 2 with image 3 As shown, an energy-saving and environmentally friendly roller cage type overrunning clutch for loaders includes an outer ring gear 1, an intermediate input shaft 2, an inner ring cam 3, a roller cage 4 and a roller 5. The outer ring The gear 1 is provided with an intermediate input shaft 2, the intermediate input shaft 2 is provided with an inner ring cam 3, the inner ring cam 3 is provided with a roller cage 4, and the roller cage 4 is A roller groove 8 and a spring groove 9 are provided. The roller groove 8 is provided with a roller 5, the spring groove 9 is provided with a spring 6, and the roller 5 and the inner ring cam 3 work surface In contact with the raceway surface of the outer ring gear, a locking plate 7 is provided between one end surface of the intermediate input shaft 2 and one end surface of the inner ring cam 3, and the locking plate 7 is evenly provided with three locks along the circumferential dire...

Embodiment 3

[0025] Example 3: Such as figure 1 , figure 2 with image 3 As shown, an energy-saving and environmentally friendly roller cage type overrunning clutch for loaders includes an outer ring gear 1, an intermediate input shaft 2, an inner ring cam 3, a roller cage 4 and a roller 5. The outer ring The gear 1 is provided with an intermediate input shaft 2, the intermediate input shaft 2 is provided with an inner ring cam 3, the inner ring cam 3 is provided with a roller cage 4, and the roller cage 4 is A roller groove 8 and a spring groove 9 are provided. The roller groove 8 is provided with a roller 5, the spring groove 9 is provided with a spring 6, and the roller 5 and the inner ring cam 3 work surface In contact with the outer ring gear raceway, a locking plate 7 is provided between one end surface of the intermediate input shaft 2 and one end surface of the inner ring cam 3, and the locking plate 7 is evenly provided with three locks along the circumferential direction claw. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com