Anti-slip cover for non-pre-tightening bolt connection

A technology of non-pretightening force bolts and anti-loosening sleeves, which is applied in the direction of connecting components, bolts, threaded fasteners, etc., can solve the problems of affecting work efficiency and inconvenient use, and achieves the effect of reliable anti-loosening effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

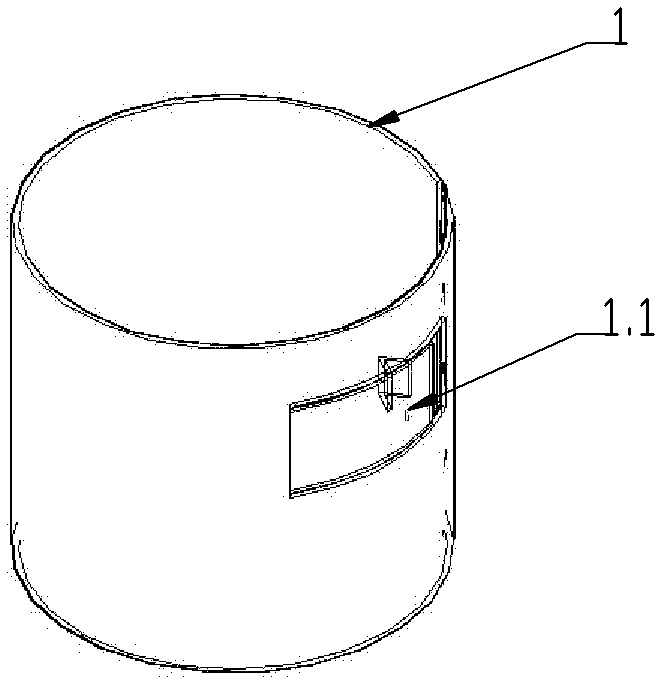

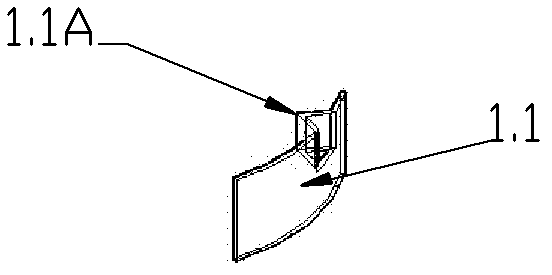

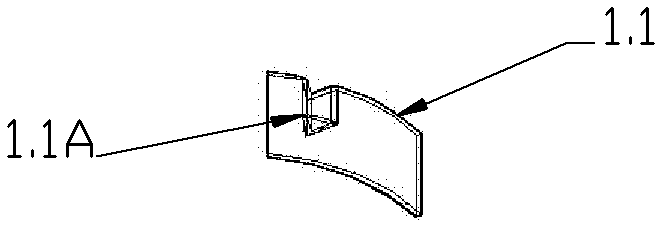

[0021] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 It is a structural schematic diagram and an effect drawing of the first embodiment of the present invention, wherein Figure 1 to Figure 4 is a schematic diagram of the structure, in order to make the display clearer, figure 2 and image 3 It is a schematic diagram of the combined structure of the shrapnel 1.1, image 3 for figure 2 The view after turning an angle; Figure 5 to Figure 7 It is a schematic diagram of the use effect. Figure 1 to Figure 4 As shown in , this embodiment includes a bolt body 2 with a concave hole 2.1 and an elastic anti-off sheath 1 sleeved at the end of the bolt body. An elastic sheet 1.1 is arranged on the anti-off sheath 1. On the elastic sheet 1.1 The first protrusion 1.1A is set on the top, and the first protrusion 1.1A is facing inward, and the anti-off sleeve is sleeved on the end of the bolt body from the outside. The first protrusion 1.1A is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com