Wind power sectional-type blade

A segmented blade technology, which is applied in wind power generation, wind turbine components, wind turbines, etc., can solve the problems of large-scale blade transportation difficulties, affecting blade aerodynamic performance, and increasing manufacturing difficulty, so as to avoid transportation The effect of exceeding the limit and inconvenient transportation, facilitating subsequent transportation operations, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

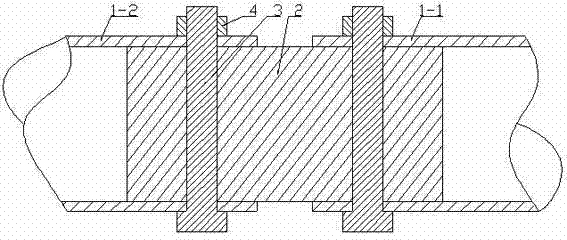

[0018] see figure 1 : the present invention divides a complete blade of design into two sections, and manufactures them respectively until molding, that is, the upper section 1-1 of the blade and the lower section 1-2 of the blade, the upper section 1-1 of the blade and the lower section 1-2 of the blade are hollow structures, The upper section 1-1 of the blade and the lower section 1-2 of the blade have butt joint ends respectively. 2 connected into a whole.

[0019] The above-mentioned connecting member is mainly composed of a connecting base 2 , a plurality of blade connecting bolts 3 and a corresponding number of nuts 4 . Wherein, the connection base 2 is a whole, and the external contours of its two ends are respectively matched with the internal contours of the butt joint ends of the blade upper section 1-1 and the blade lower section 1-2, and the two ends of the connection base 2 Respectively extend to the butt ends of the blade upper section 1-1 and the blade lower s...

Embodiment 2

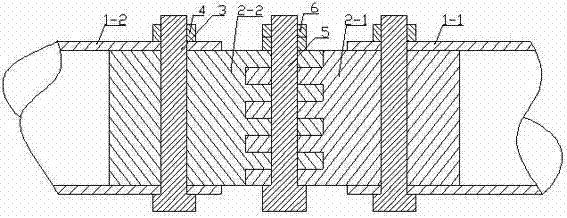

[0021] see figure 2 : the present invention divides the blade into two sections of blades, i.e. the upper blade 1-1 and the lower blade 1-2, the upper blade 1-1 and the lower blade 1-2 are hollow structures, the upper blade 1-1 and the lower blade 1 -2 have butt joint ends respectively, and connecting members are respectively connected to the butt joint ends of the blade upper section 1-1 and the blade lower section 1-2, so as to connect the blade upper section 1-1 and the blade lower section 1-2 as a whole.

[0022] The above-mentioned connecting member is mainly composed of a connecting base 2 , a plurality of blade connecting bolts 3 and a corresponding number of nuts 4 . Wherein, the connection base 2 is composed of a first connection base 2-1 and a second connection base 2-2, and the first connection base 2-1 has an outer profile matching the internal profile of the butt end of the blade upper section 1-1. The end of the second connecting base 2-2 has an outer profile m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com