Ultraviolet curable adhesive with high light transmittance

A high light transmittance, adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problem of color fidelity, unsatisfactory bonding hardness and strength, and slow curing speed of adhesives that affect electronic products. problems, to achieve the effect of curing speed controllability, excellent high and low temperature alternating performance, and fast curing speed

Active Publication Date: 2012-06-27

SHENZHEN PROSPER DOBOND TECH

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing ultraviolet curing adhesives have slow curing speed, low production efficiency, high energy consumption, and high cost during production; the light transmission performance of the adhesive is poor, which affects the color fidelity of electronic products; Hardness and strength are not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

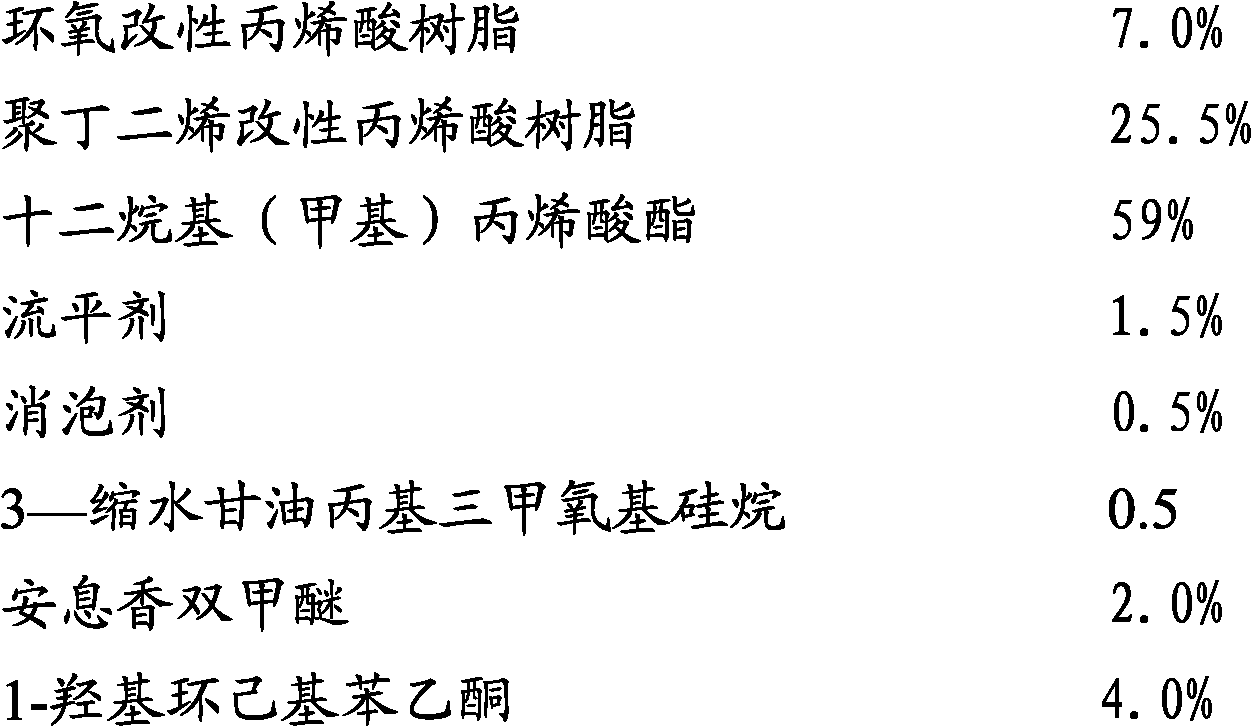

Embodiment 1

[0010] The present embodiment is configured according to the raw materials of the following weight percentages:

[0011]

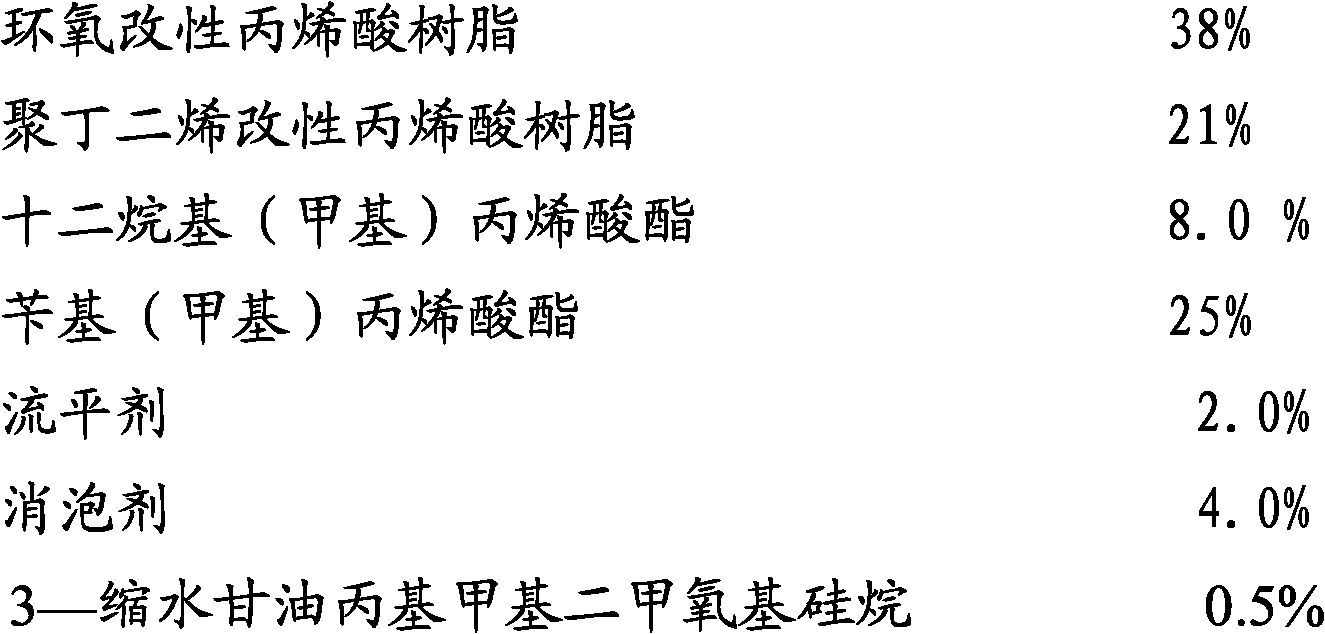

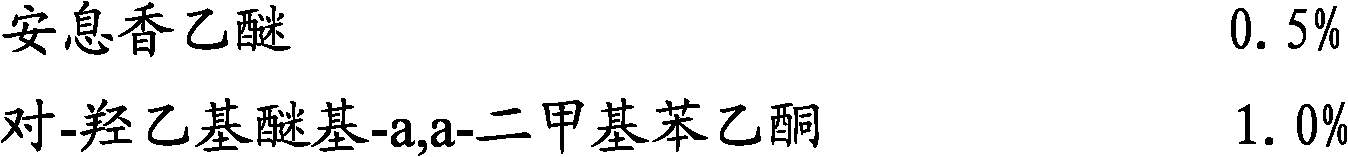

Embodiment 2

[0013] The present embodiment is configured according to the raw materials of the following weight percentages:

[0014]

[0015]

Embodiment 3

[0017] The present embodiment is configured according to the raw materials of the following weight percentages:

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an ultraviolet curable adhesive with high light transmittance. The ultraviolet curable adhesive provided by the invention is prepared from the following raw materials of: by weight, 5.8-59% of modified acrylic acid oligomer resin, 5.8-59% of an acrylic acid monomer, 2-10% of an auxiliary agent, 0.5-15% of a silane coupling agent, and 1.5-10.5% of a photoinitiator. With the adoption of the above components in proportions, the adhesive provided by the invention has fast curing rate and excellent optical properties, the glue solution is colorless and transparent, its light transmittance after curing is greater than 95%, cure shrinkage is small, the internal stress is low, and caking capability is strong.

Description

technical field [0001] The invention relates to an ultraviolet (UV) curable adhesive, in particular to an ultraviolet (UV) curable adhesive with high light transmittance, which can be used for bonding glass to glass. Background technique [0002] Ultraviolet (UV) is invisible to the naked eye, and is a section of electromagnetic radiation other than visible light, with a wavelength in the range of 10-400nm. Ultraviolet (UV) curing adhesive refers to a type of adhesive that must be cured by ultraviolet light. It can be used as an adhesive or as a glue for paints, coatings, inks, etc. The principle of UV glue curing is: the photoinitiator (or photosensitizer) in the UV curing material absorbs ultraviolet light to generate active free radicals or cations under the irradiation of ultraviolet light, triggering chemical reactions of monomer polymerization, crosslinking and grafting, so that The adhesive changes from liquid to solid within seconds. The existing ultraviolet curing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J4/02

Inventor 刘行袁海宾贺珍

Owner SHENZHEN PROSPER DOBOND TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com