Slow-release urea and production method thereof

A slow-release urea, production method technology, applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of land, environmental impact, low nutrient utilization rate, resource waste, etc., achieve low operating cost, eliminate excessive waste, The effect of slowing down the release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

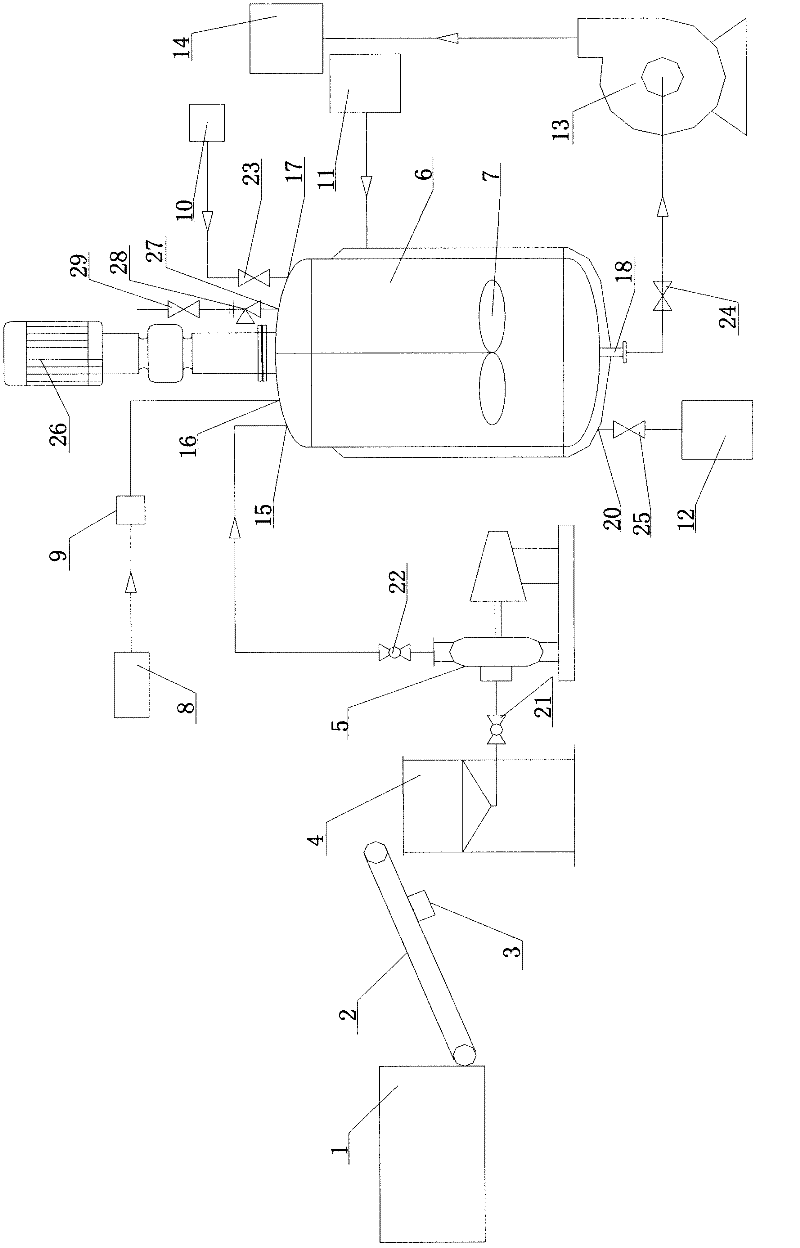

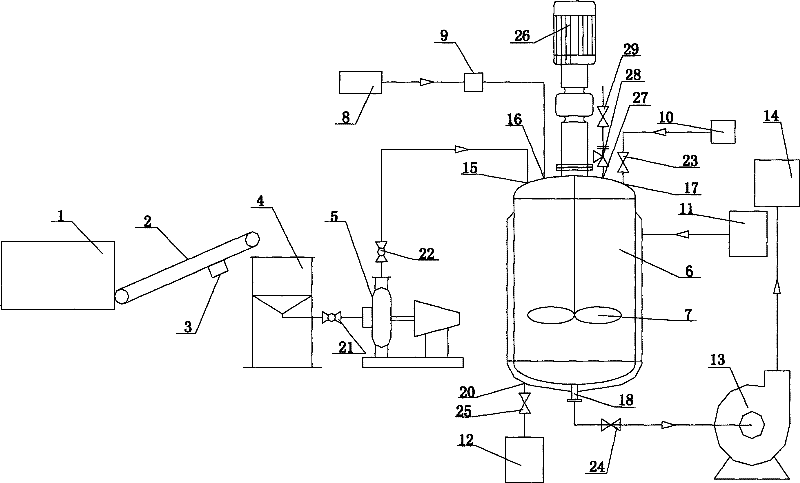

[0025] When making 1000 kg of the present invention, 30 kg of attapulgite powder, 1 kg of polyacrylamide, 1 kg of quartz stone powder and 968 kg of molten urea solution.

[0026] 1. Put 30 kg of attapulgite powder, 1 kg of polyacrylamide, and 1 kg of quartz stone powder into the slow-release agent feeding device 1 and mix them through the metering belt 2, slow-release agent tank 4 and powder pump 5 into the urea solution tank 6 Inside;

[0027] Two, 968 kilograms of molten urea solutions that come from evaporation system 8 in urea production are 968 kilograms of molten urea solutions that are more than 99.5% and enter in the urea solution tank 6 through the pipeline that flow meter 9 is installed;

[0028] Three, the sustained-release agent mixed in step 1 and the molten urea solution in step 2 are placed on the urea solution tank 6 and uniformly mixed, and the pressure of the urea solution tank 6 is 0.5MPa, and the temperature is 135°C;

[0029] 4. Put the mixed mixture in s...

Embodiment 2

[0032] When making 2000 kg of the present invention, 120 kg of attapulgite powder, 10 kg of polyacrylamide, 10 kg of quartz stone powder and 10 kg of molten urea solution.

[0033] 1. Put 120 kg of attapulgite powder, 10 kg of polyacrylamide, and 10 kg of quartz stone powder into the slow-release agent feeding device 1 and mix them into the urea solution tank 6 through the metering belt 2, the slow-release agent tank 4 and the powder pump 5 Inside;

[0034] Two, 1860 kilograms of molten urea solution that the concentration that comes from evaporation system 8 in urea production is more than 99.5% enters in the urea solution tank 6 by the pipeline that flow meter 9 is installed;

[0035] Three, the sustained-release agent mixed in step 1 and the molten urea solution in step 2 are placed on the urea solution tank 6 and uniformly mixed, and the pressure of the urea solution tank 6 is 0.55MPa, and the temperature is 140°C;

[0036] 4. Put the mixture mixed in step 3 into the gran...

Embodiment 3

[0039] When making 3000 kg of the present invention, 360 kg of attapulgite powder, 30 kg of polyacrylamide, 30 kg of quartz stone powder and 2580 kg of molten urea solution.

[0040] 1. Put 360 kg of attapulgite powder, 30 kg of polyacrylamide, and 30 kg of quartz stone powder into the slow-release agent feeding device 1 and mix them into the urea solution tank 6 through the metering belt 2, the slow-release agent tank 4 and the powder pump 5 Inside;

[0041] Two, 2580 kilograms of molten urea solution that the concentration that comes from evaporation system 8 in urea production is more than 99.5% enters in the urea solution tank 6 by the pipeline that flow meter 9 is installed;

[0042] Three, the sustained-release agent mixed in the step 1 and the molten urea solution in the step 2 are placed on the urea solution tank 6 and uniformly mixed, and the pressure of the urea solution tank 6 is 0.6MPa, and the temperature is 145°C;

[0043] 4. Put the mixture mixed in step 3 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com