Chitosan coated alga bioorganic fertilizer and preparation method thereof

A bio-organic fertilizer, chitosan coating technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of large loss of active substances, no research on the treatment of seaweed organic fertilizer coating, and achieve low cost and low price. Inexpensive source and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

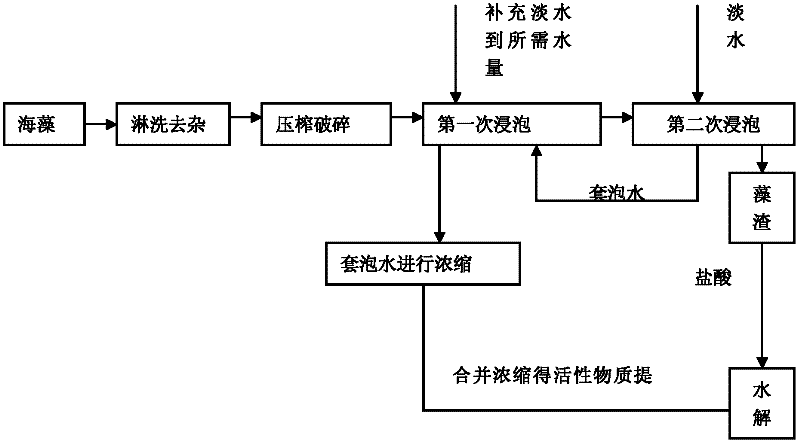

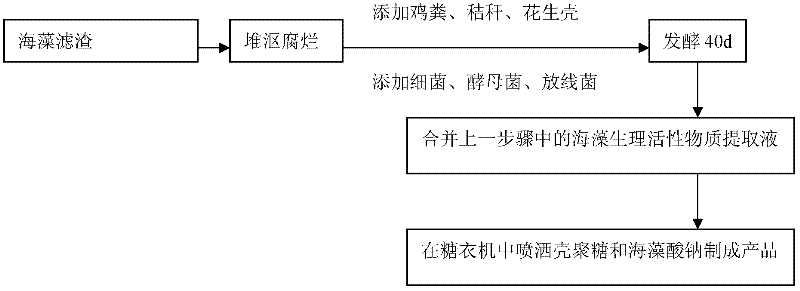

[0031] The first is the preparation of the extract of physiologically active substances from seaweed, specifically: wash the collected kelp to remove impurities, divide it into multiple parts, each part is 1000kg, press and crush it into small pieces of about 3cm, add 5000kg to each of the I pool and II pool For fresh water, first soak the kelp in pool I for 60 minutes (the time is too short, not enough to soak out the active substances, and the time is too long, which increases the water absorption of the kelp, thereby increasing the recovery rate of the active substances, and the leaching rate of 60 minutes can reach 85% , the highest can reach 94%), the soaking water in pool I is filtered out and concentrated, the kelp is controlled and transferred to pool II, submerged again for 60 minutes, the kelp is taken out for the next step of fermentation, new water is added to pool I, and enough water is added to pool II In fresh water, the next batch of kelp is soaked in pool II fo...

Embodiment 2

[0035] The first is the preparation of the extract of physiologically active substances from seaweed, specifically: wash the collected Enteromorpha to remove impurities, weigh multiple portions, each portion is 1000kg, press and crush it into small pieces of about 3cm, each of the I pool and II pool Add 5000kg of fresh water, first soak Enteromorpha in Pond I for 80min, (according to the physical characteristics of seaweed, the soaking time can be extended to 80min appropriately), filter out and concentrate the soaking solution, add 5000kg of fresh water to Pond I, and transfer the kelp to Pond I Immerse pool II again for 80 minutes, add enough fresh water to pool II, exchange the functions of pool I and pool II, repeat this process, concentrate the leachate for later use; hydrolyze the soaked enteromorpha at 60°C under the condition of pH 3.0 (adjusted with hydrochloric acid) After 6 hours, the hydrolyzate was centrifuged at 4000 rpm / min for 5 minutes, the supernatant was comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com