Method for preparing MnO2 film with multi-layer structure

A technology of manganese dioxide and layered structure, which is applied in the fields of chemical industry and material science and engineering, and can solve problems such as the failure to realize the effective control of the structure of thin film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

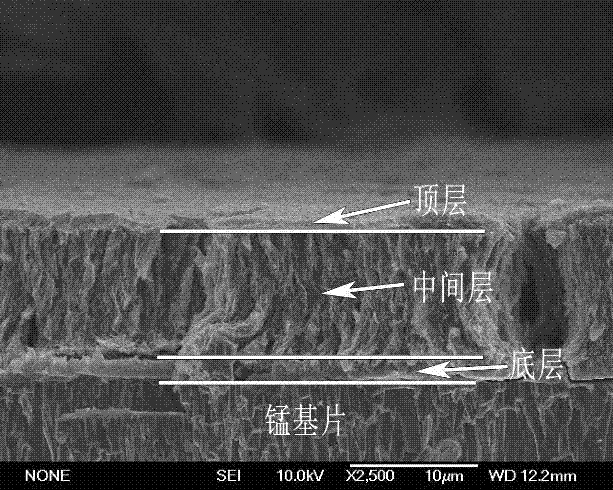

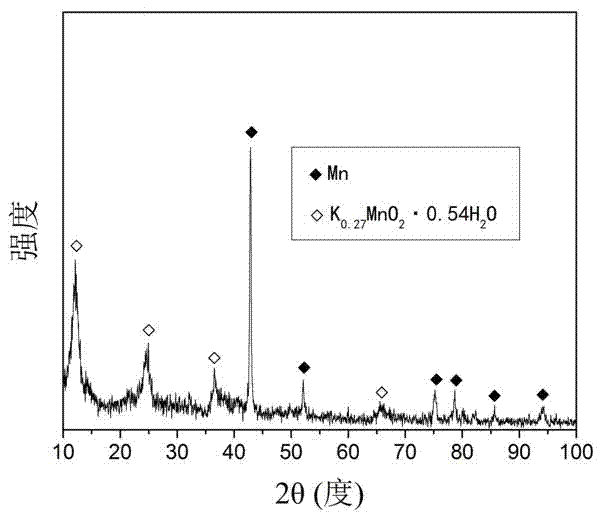

[0020] Weigh 0.632g of potassium permanganate, add 20mL of deionized water, and stir magnetically for 15 minutes until a uniform purple-red solution is formed; add hydrochloric acid solution dropwise to the solution to adjust the pH to pH=1. Move the solution into a 25mL stainless steel reaction kettle lined with polytetrafluoroethylene, add a pre-treated metal manganese substrate and fix it, and seal the reaction kettle. The reactor was heated to 150°C and kept at this temperature for 24 hours. Take out the reaction kettle and cool to room temperature. Open the reaction kettle, take out the sample, clean it with deionized water, and dry it to obtain a manganese dioxide film with a three-layer structure.

Embodiment 2

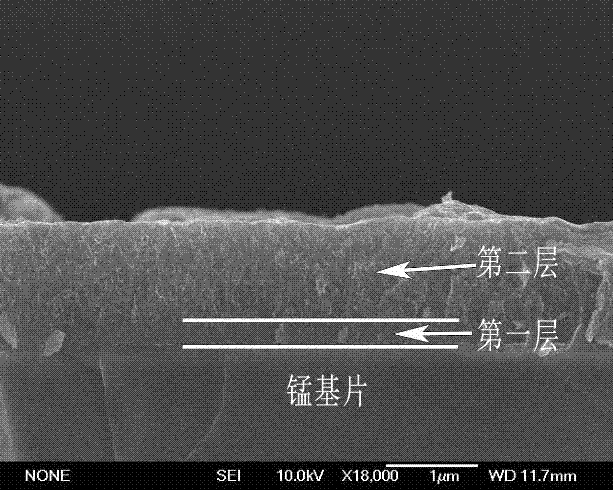

[0022] Weigh 0.174g of potassium permanganate, add 20mL of deionized water, and stir magnetically for 15 minutes until a uniform purple-red solution is formed; add hydrochloric acid solution dropwise to the solution to adjust the pH to pH=3. Move the solution into a 25mL stainless steel reaction kettle lined with polytetrafluoroethylene, add a pre-treated metal manganese substrate and fix it, and seal the reaction kettle. The reactor was heated to 150°C and kept at this temperature for 12 hours. Take out the reaction kettle and cool to room temperature. Open the reaction kettle, take out the sample, clean it with deionized water, and dry it to obtain a manganese dioxide film with a double-layer structure.

Embodiment 3

[0024] Weigh 0.79g of potassium permanganate, add 20mL of deionized water, and stir magnetically for 15 minutes until completely dissolved; add hydrochloric acid solution dropwise to the solution, and adjust the pH to pH=2. Move the solution into a 25mL stainless steel reaction kettle lined with polytetrafluoroethylene, add a pre-treated metal manganese substrate and fix it, and seal the reaction kettle. The reactor was heated to 170°C and kept at this temperature for 20 hours. Take out the reaction kettle and cool to room temperature. Open the reaction kettle, take out the sample, clean it with deionized water, and dry it to obtain a manganese dioxide film with a three-layer structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com