Method and device for recycling waste clear liquid produced in process for producing sodium carbonate by ammonia-soda process

A cyclic recovery and waste liquid technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of energy waste, complex process, high production cost, and eliminate chemical pollution. , the effect of high economic efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

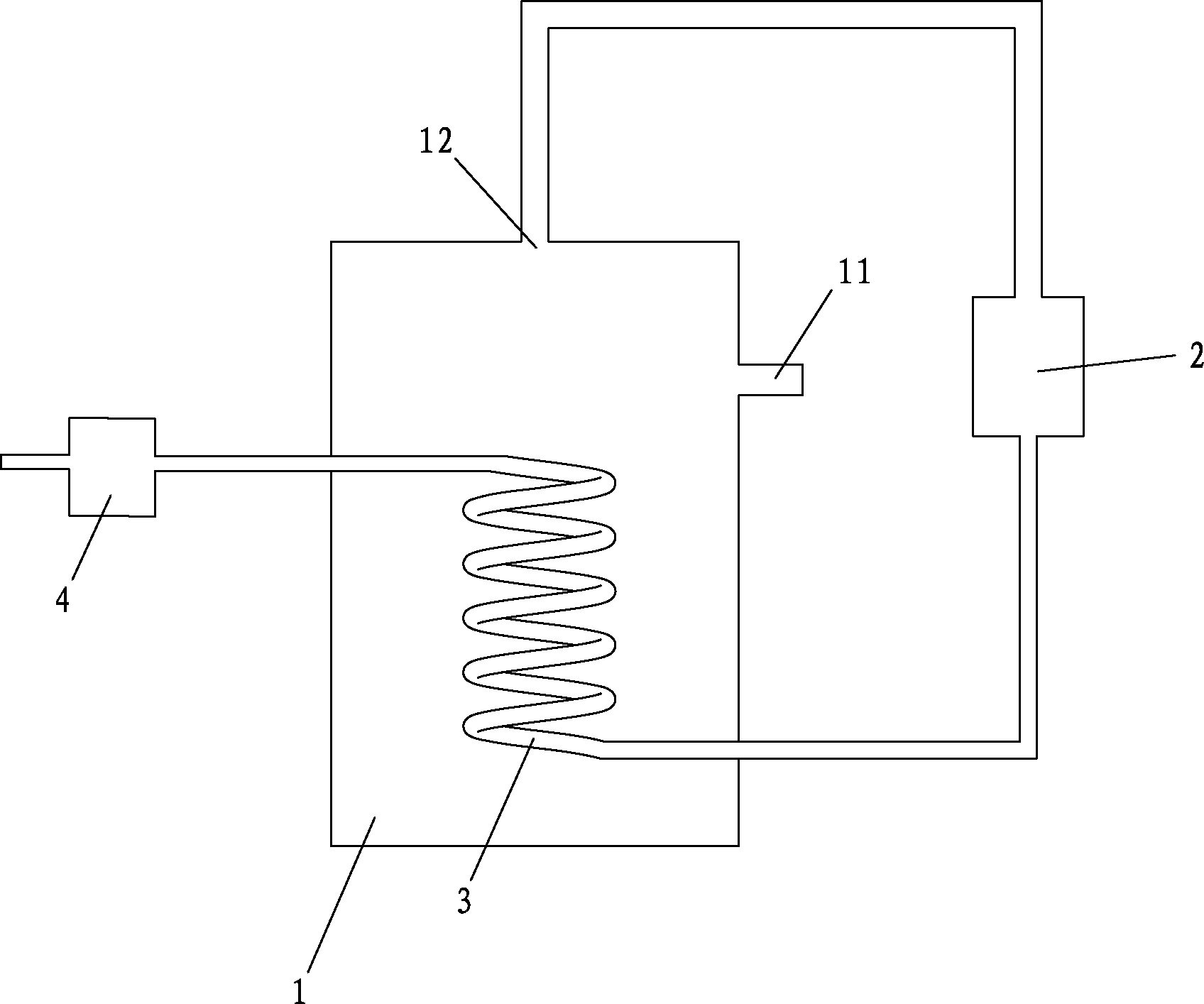

[0041] Such as figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0042] Step A, drain the waste clear liquid obtained after clarification and deslagging treatment of 10 cubic meters of distillation waste liquid produced by the ammonia-soda factory to produce soda ash into the waste liquid tank 1; or pass the distillation waste liquid produced by the ammonia-soda factory to produce soda ash The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0043] Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0044] Step C. When the water ev...

Embodiment 2

[0055] Such as figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0056] Step A, drain the waste clear liquid obtained after clarification and deslagging treatment of 10 cubic meters of distillation waste liquid produced by the ammonia-soda factory to produce soda ash into the waste liquid tank 1; or pass the distillation waste liquid produced by the ammonia-soda factory to produce soda ash The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0057] Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0058] Step C. When the water ev...

Embodiment 3

[0069] Such as figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0070] Step A, drain the waste clear liquid obtained after clarification and deslagging treatment of 10 cubic meters of distillation waste liquid produced by the ammonia-soda factory to produce soda ash into the waste liquid tank 1; or pass the distillation waste liquid produced by the ammonia-soda factory to produce soda ash The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0071]Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0072] Step C. When the water eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com