Environment-friendly packaging barrel for residual-free chemical material liquid

A residue-free, environmentally friendly technology, used in packaging, transportation and packaging, cans/barrels/barrels, etc., can solve the problems of environmental pollution, thick barrel walls, difficult to grasp, etc., to achieve easy popularization and application, increase the degree of stability, Solve the effect of easy sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

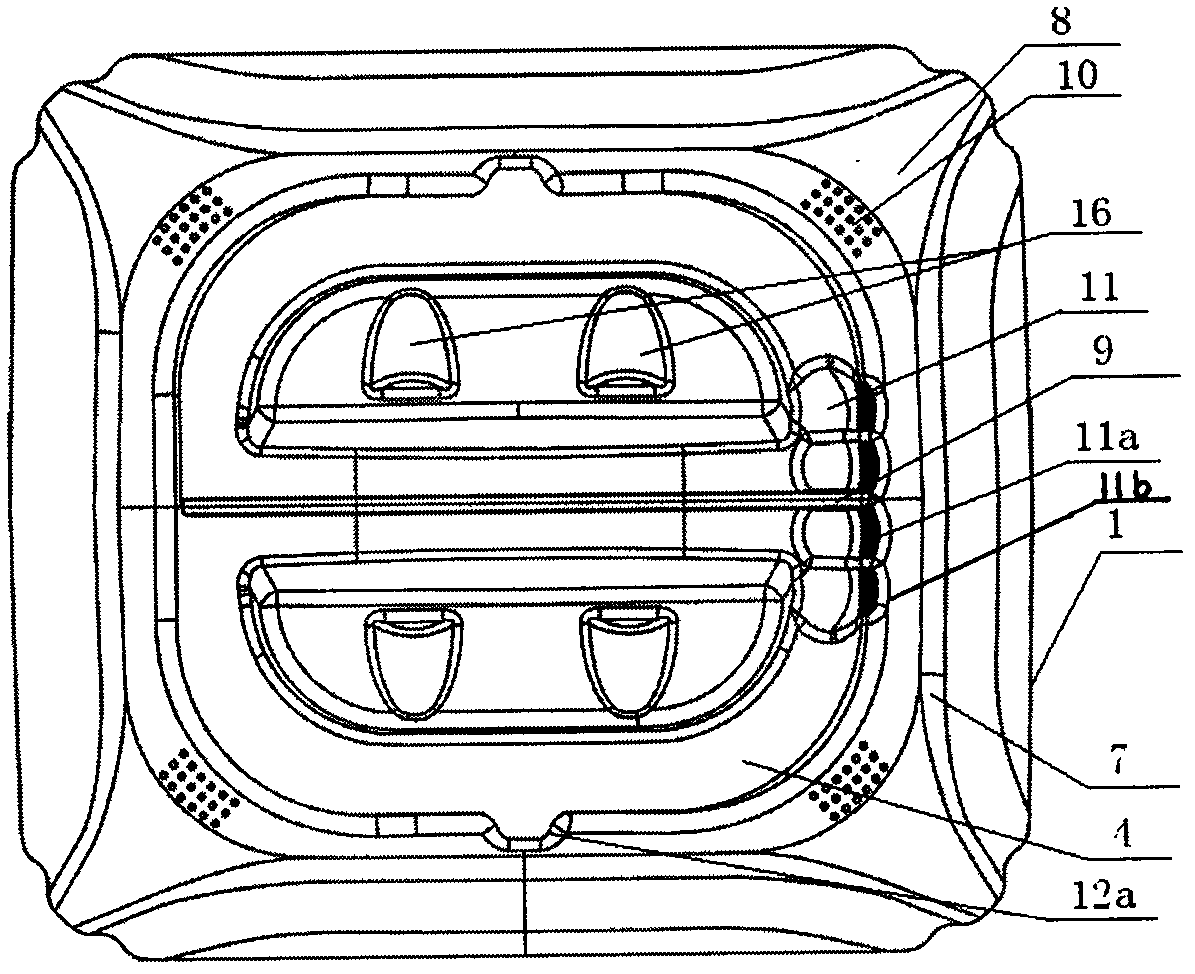

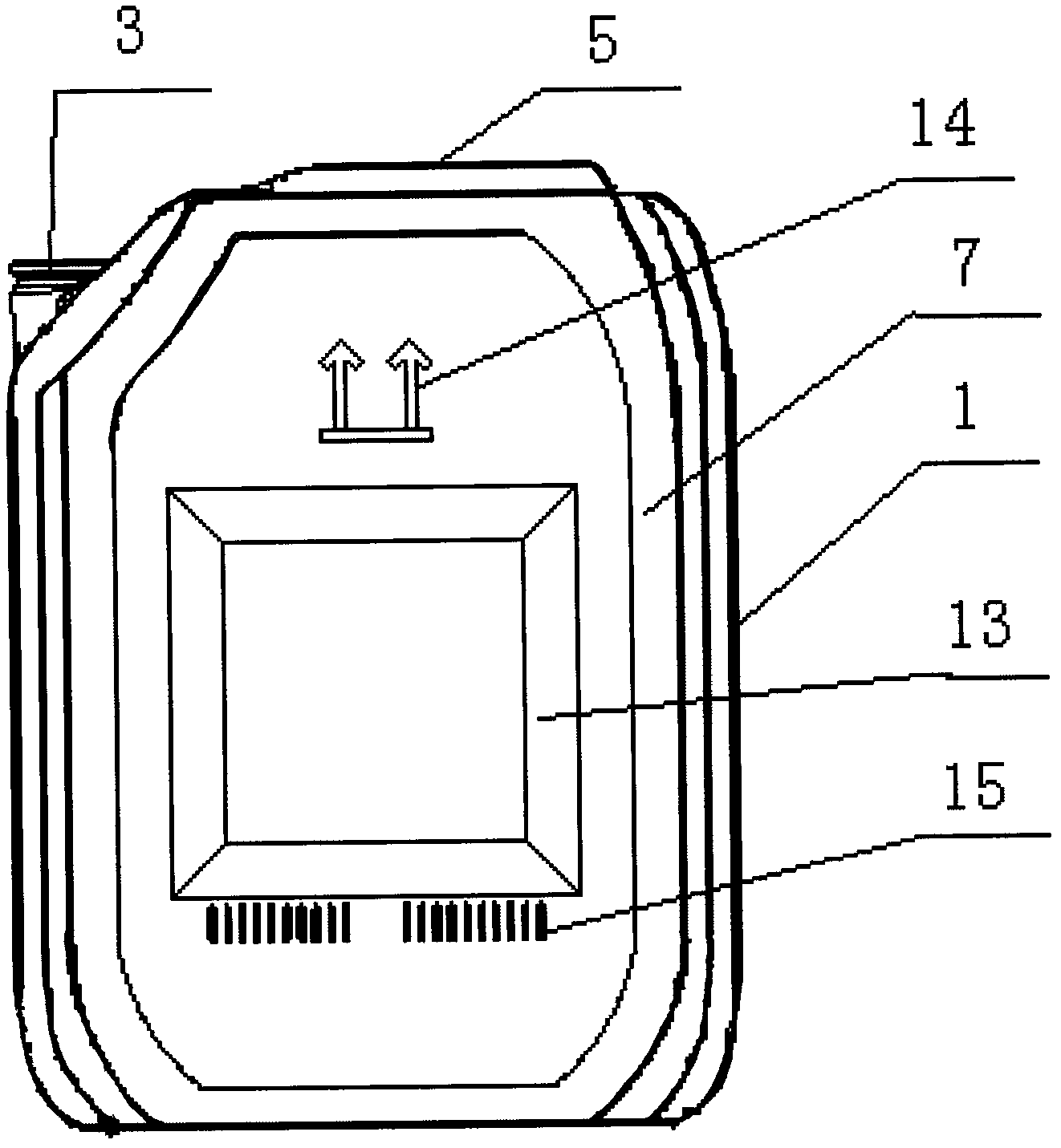

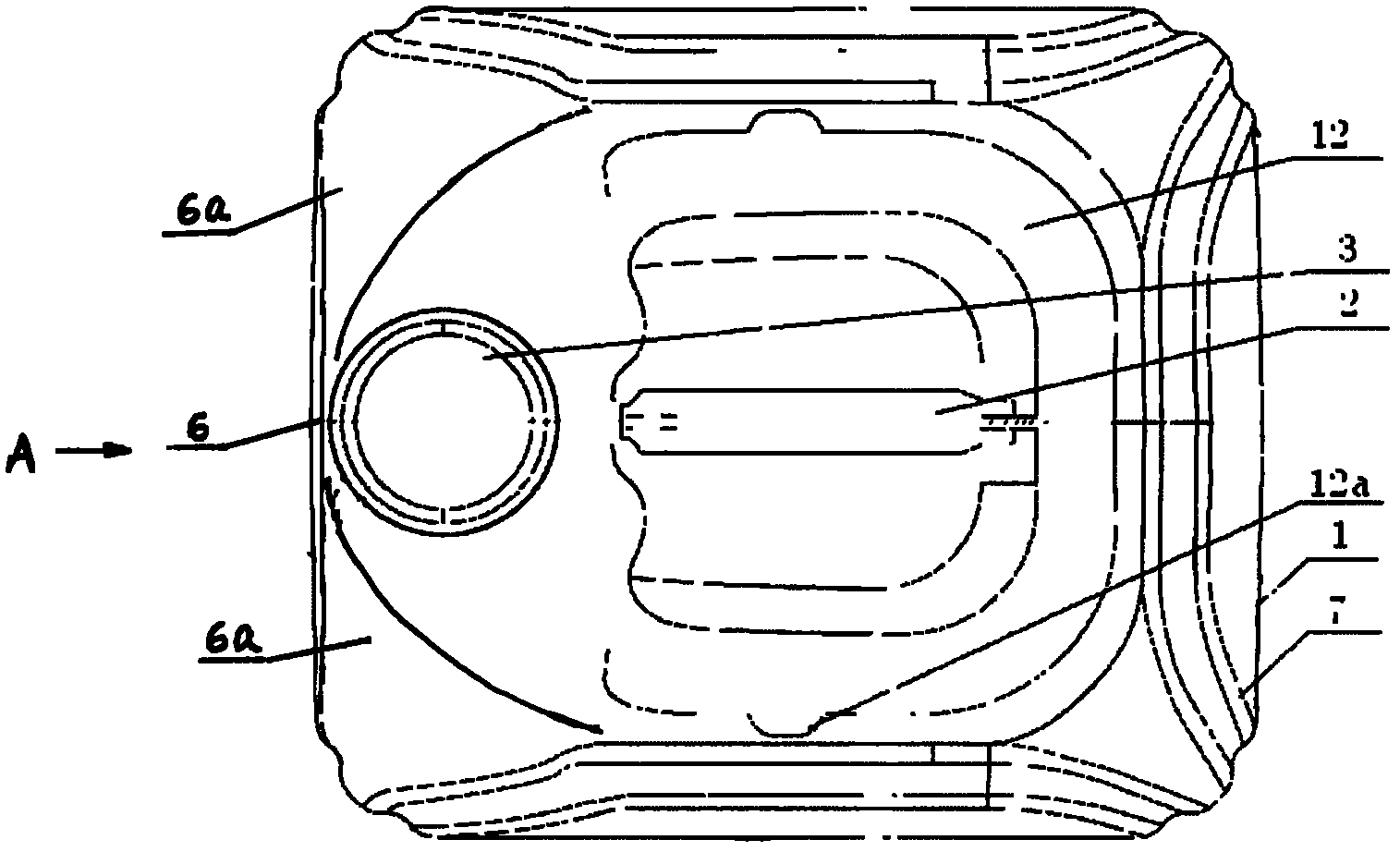

[0022] Embodiment 1: a kind of environment-friendly packaging barrel without residual chemical material liquid (see Figure 1-4 (i.e. edge mouth barrel), including square barrel body 1, barrel handle 2 and barrel mouth 3, barrel body 1 is composed of four walls, barrel top and barrel bottom to form a whole barrel, barrel handle 2 and barrel mouth 3 are placed on the top of barrel , and the barrel mouth 3 is at the side wall of the barrel body 1 (see image 3 ), the top of the barrel and the bottom of the barrel respectively have a positioning convex 5 and a positioning concave 4 corresponding to each other, and it is characterized in that the junction of the barrel mouth 3 and the barrel body 1 has a residual liquid gathering belly 6 without dead ends, and the residual liquid gathering belly 6 Lower than the mouth of the barrel, it is in the shape of a smear-shaped funnel that does not retain residual liquid 6a (see Figure 4 ); said barrel top and barrel bottom each have cor...

Embodiment 2

[0029] Embodiment 2: a kind of environment-friendly packaging barrel without residual chemical material liquid (see Figure 5-7 i.e. corner mouth barrel), including square barrel body 1, barrel handle 2 and barrel mouth 3, barrel body 1 is composed of four walls, barrel top and barrel bottom to form a whole barrel, barrel handle 2 and barrel mouth 3 are placed on the top of barrel , and the barrel mouth 3 is at the corner of the barrel body 1 (see Figure 7 ), the top of the barrel and the bottom of the barrel respectively have a positioning convex 5 and a positioning concave 4 corresponding to each other, and it is characterized in that the junction of the barrel mouth 3 and the barrel body 1 has a residual liquid gathering belly 6 without dead ends, and the residual liquid gathering belly 6 Lower than the mouth of the barrel, it is in the shape of a smear-shaped funnel that does not retain residual liquid 6a (see Figure 6 , 7 ); said barrel top and barrel bottom each have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com