Inclined plate type device for preventing lump coal from being broken in process of entering bin

A crushing device, inclined plate technology, applied in conveyor control device, transportation and packaging, loading/unloading, etc., can solve problems such as inability to adapt to large storage capacity, low storage capacity utilization, narrow working range, etc., to improve storage capacity utilization. rate, realize automatic control, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

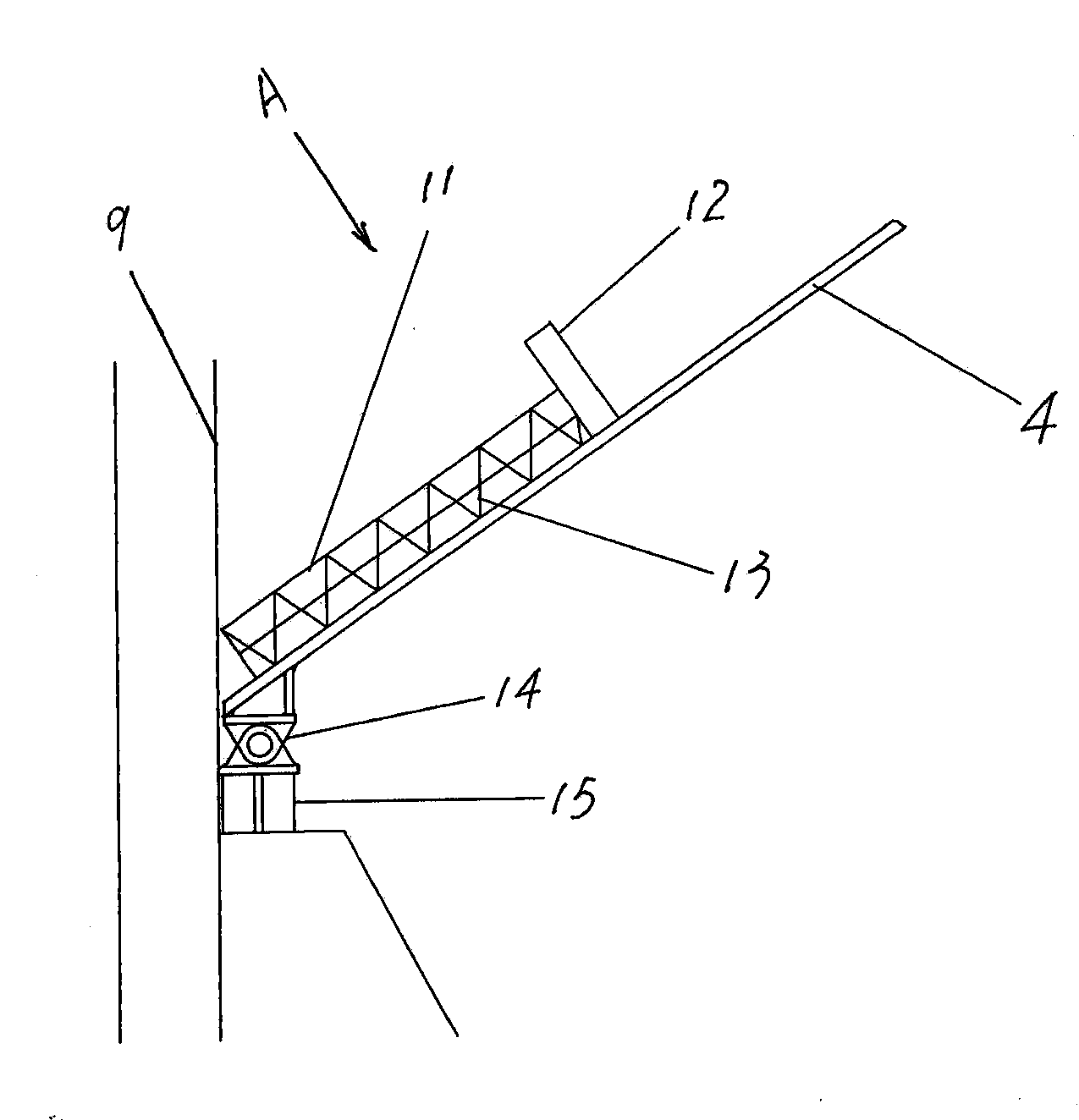

[0012] Such as figure 1 As shown, a track 10 is laid on the top of the coal bunker 9, and a reversible belt conveyor 1 is arranged on the track 10 to realize its reversible two-way movement, which is convenient for high-position warehouse allocation; on the side of the coal bunker 9, the reversible belt conveyor 1 machine A buffer short slant plate 2 is installed under the head, and the two sides of the buffer short slant plate 2 are provided with 200mm high guard plates to prevent the lump coal from falling sideways during the sliding process, and to gather the lump coal. A buffer area 3 is formed with the upper end of the sloping plate 4 into the warehouse, and the lump coal is buffered and decelerated in this area, and the decelerated lump coal starts to slide slowly at a low speed along the sloping plate 4 of the warehouse by gravity; the short buffer swash plate 2 is formed by The adjustable hanger 6 is connected under the track 10, and the inclination angle of the short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com