Green tyre discharging and turning device

A technology of turning device and embryo, applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of low production efficiency, increase the workload of workers, easy deformation, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

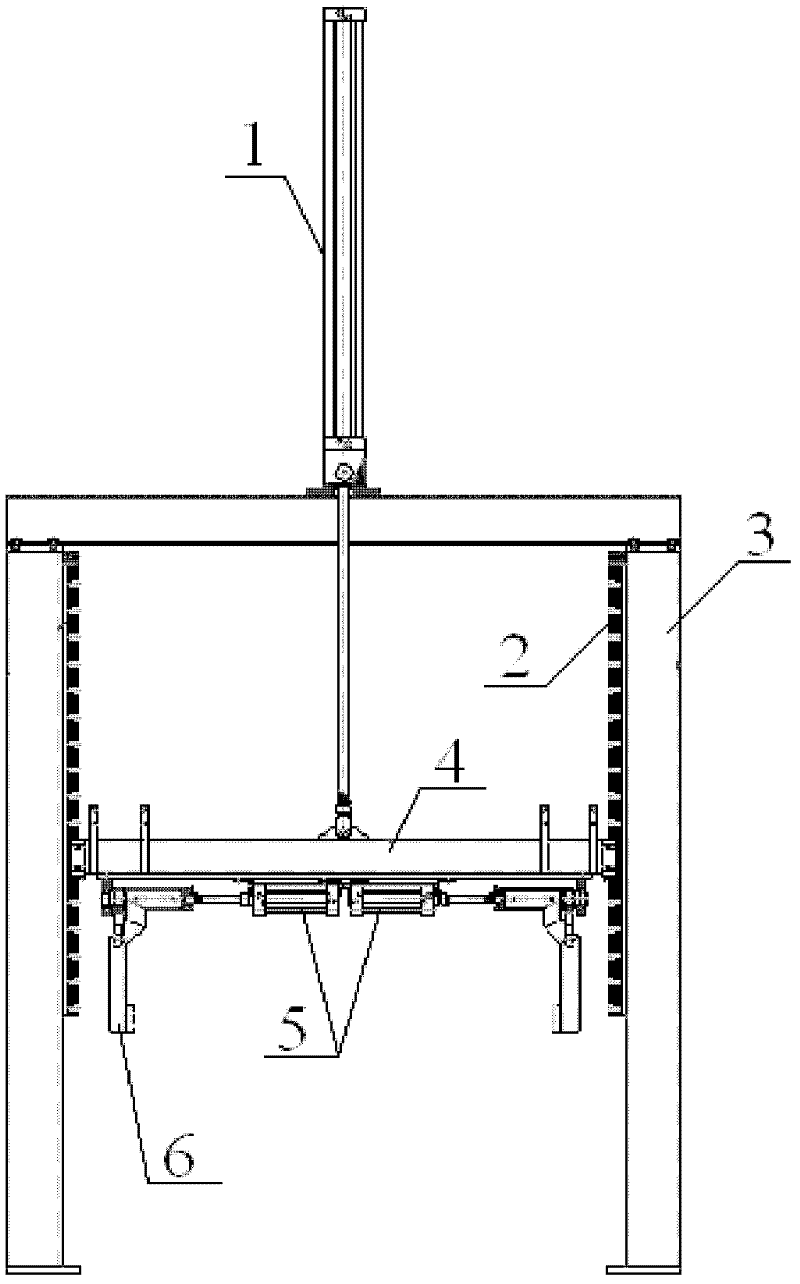

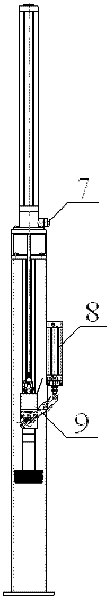

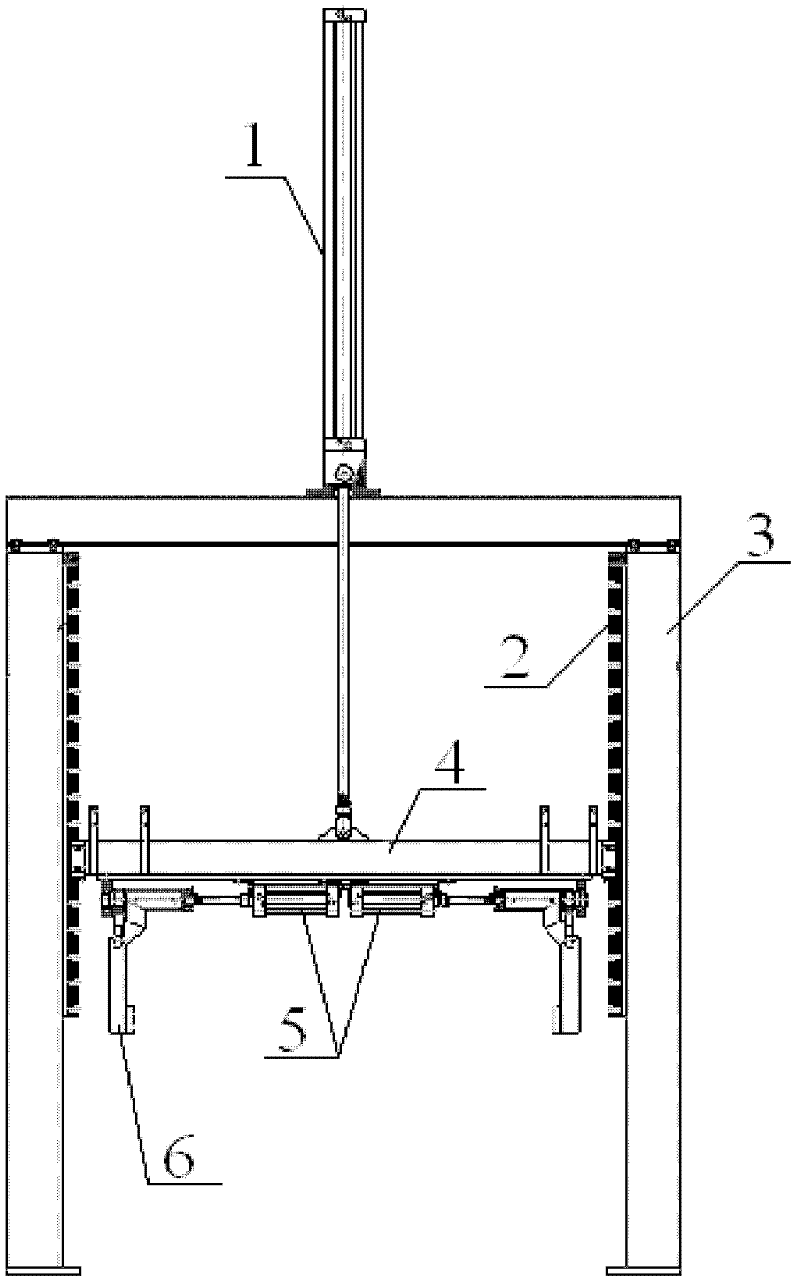

[0013] see figure 1 , 2 , a tire embryo unloading and turning device, including a bracket 3, a lifting cylinder 1 is installed on the top of the bracket 3, guide rails 2 are respectively provided on the inner walls on both sides of the bracket 3, and the guide rails 2 on the inner walls on both sides of the bracket 3 pass through A lifting mechanism 4 is installed in sliding fit, and the front end of the piston rod of the lifting cylinder 1 extends downwards and is fixedly connected with the upper end of the lifting mechanism 4; 4 The lower ends are respectively equipped with two clamping cylinders 5, and the piston rods of the two clamping cylinders 5 are fixedly connected to the inner sides of the left and right clamping mechanisms 6 respectively; 3. The front ends of the overturning cylinder 8 piston rods on the outer walls of both sides are respectively hinged with the rotating shafts of the left and right clamping mechanisms 6 through connecting rods 9;

[0014] The lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com