A barrel inner wall polishing machine

A technology of polishing machine inside the cylinder, applied in the field of polishing machine, can solve the problems of inability to guarantee the uniformity of surface finish, harsh working environment, poor polishing quality, etc., and achieve the effect of eliminating the uniformity of smoothness, good polishing quality and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

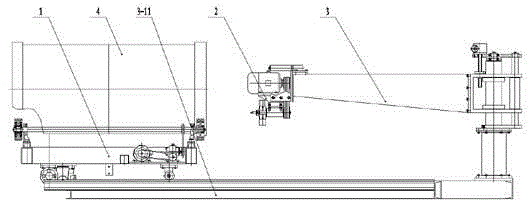

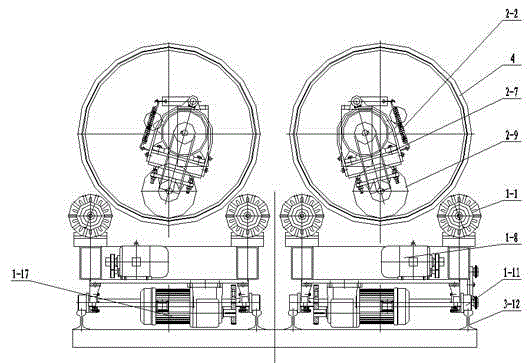

[0023] Such as figure 1 with figure 2 The cylinder inner wall polishing machine shown includes a frame rail mechanism 3 , a roller frame traveling mechanism 1 that drives the cylinder body 4 to move circumferentially and axially, and a polishing mechanism 2 that polishes the inner wall of the cylinder body 4 .

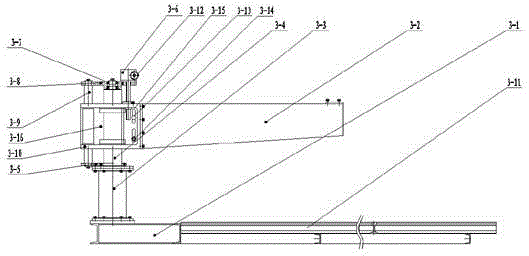

[0024] Such as image 3 As shown, the frame guide rail mechanism 3 includes a base 3-1, a cantilever 3-2, a lifting mechanism for regulating the height of the cantilever and a guide rail 3-11 arranged on the base 3-1, the cantilever is connected with the lifting mechanism, and the lifting mechanism passes through the lower column 3-3 is fixed on the base 3-1. The elevating mechanism comprises an upper column 3-4, an elevating support 3-10, an elevating seat 3-8, an elevating positioning shaft 3-9, an elevating positioning plate 3-5 and an elevating reducer 3-6, and the bottom of the upper elevating column 3-4 Fixed on the lower column, the lifting support is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com