Device for inverted assembling and welding of T-shaped sections

A technology for assembling welding and profiles, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to realize automatic fillet welding machine welding, reduce the competitiveness of enterprises, increase production costs, etc., and achieve the reduction of scribing work , Improve assembly efficiency and welding efficiency, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

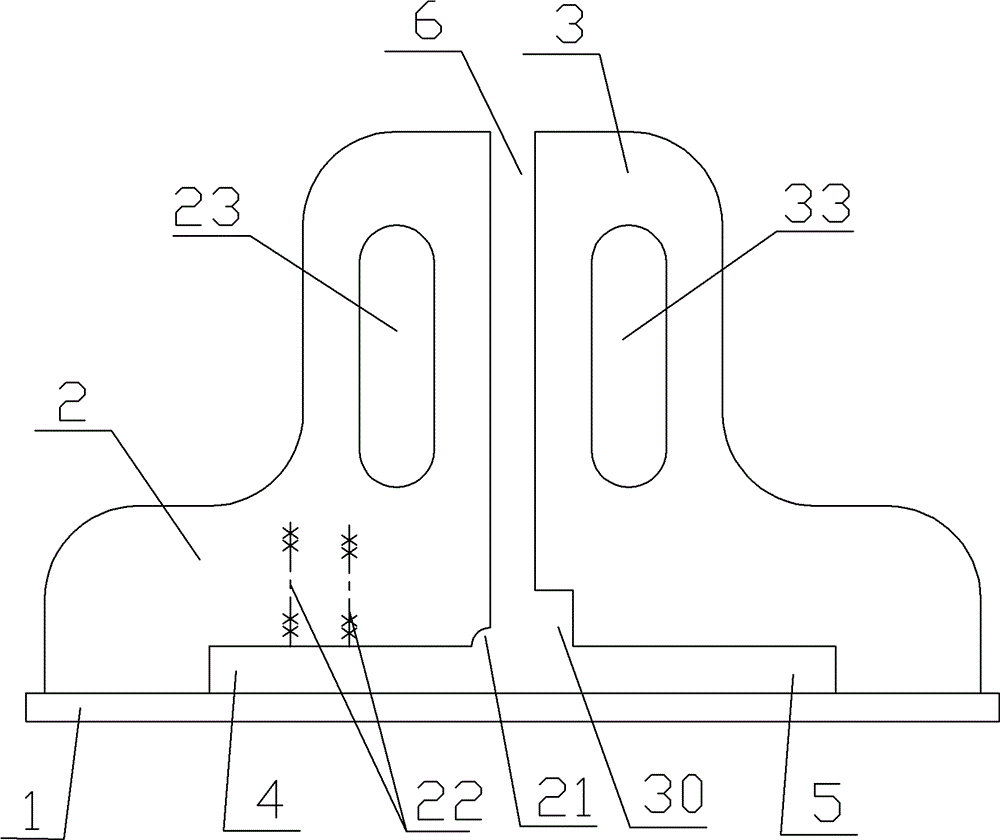

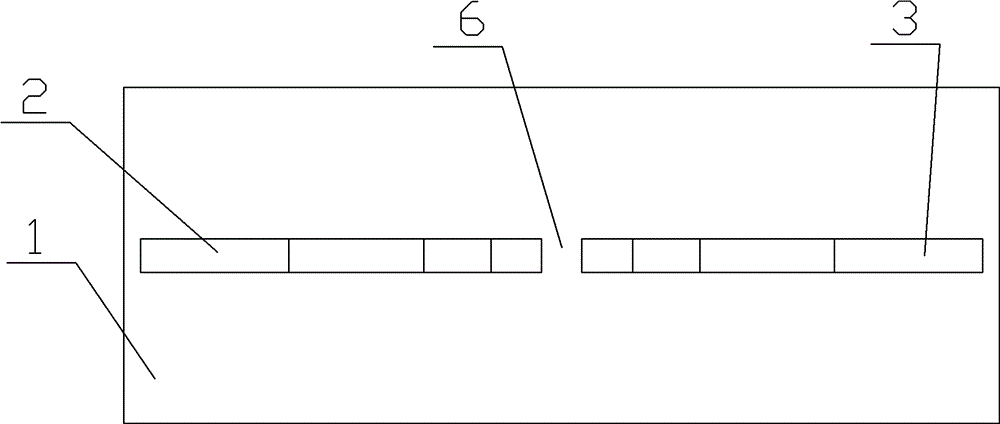

[0014] refer to figure 1 , figure 2 , a kind of device that is used for T profile inverted assembling welding provided by the present invention, comprises the bottom plate 1 that is placed horizontally, and main board 2 and sub-board 3 are installed on the bottom plate 1, is provided with T profile panel installation port between main board 2 and bottom plate 1 4. There is a T-shaped panel installation opening 5 between the sub-board 3 and the bottom plate 1, the main board 2 and the sub-board 3 are located on the same vertical surface, and the T-shaped panel installation ports 4 and 5 of the main board 2 and the sub-board 3 are arranged oppositely. A T-shaped web installation opening 6 is arranged between the main board 2 and the auxiliary board 3, and the T-shaped web installation opening 6 communicates with the T-shaped panel installation openings 4 and 5 to form an inverted T-shaped space for placing T Profiles and welding of T profiles.

[0015] Further, the main board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com