Seamless steel tube perforator piercing point on-line regulating device

A seamless steel pipe and adjustment device technology, which is applied in metal rolling and other directions, can solve the problems of large tolerance value of the front end wall thickness of steel pipe, increase of production cost, and increase of process, so as to improve quality and stability and reduce production cost , reduce the effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

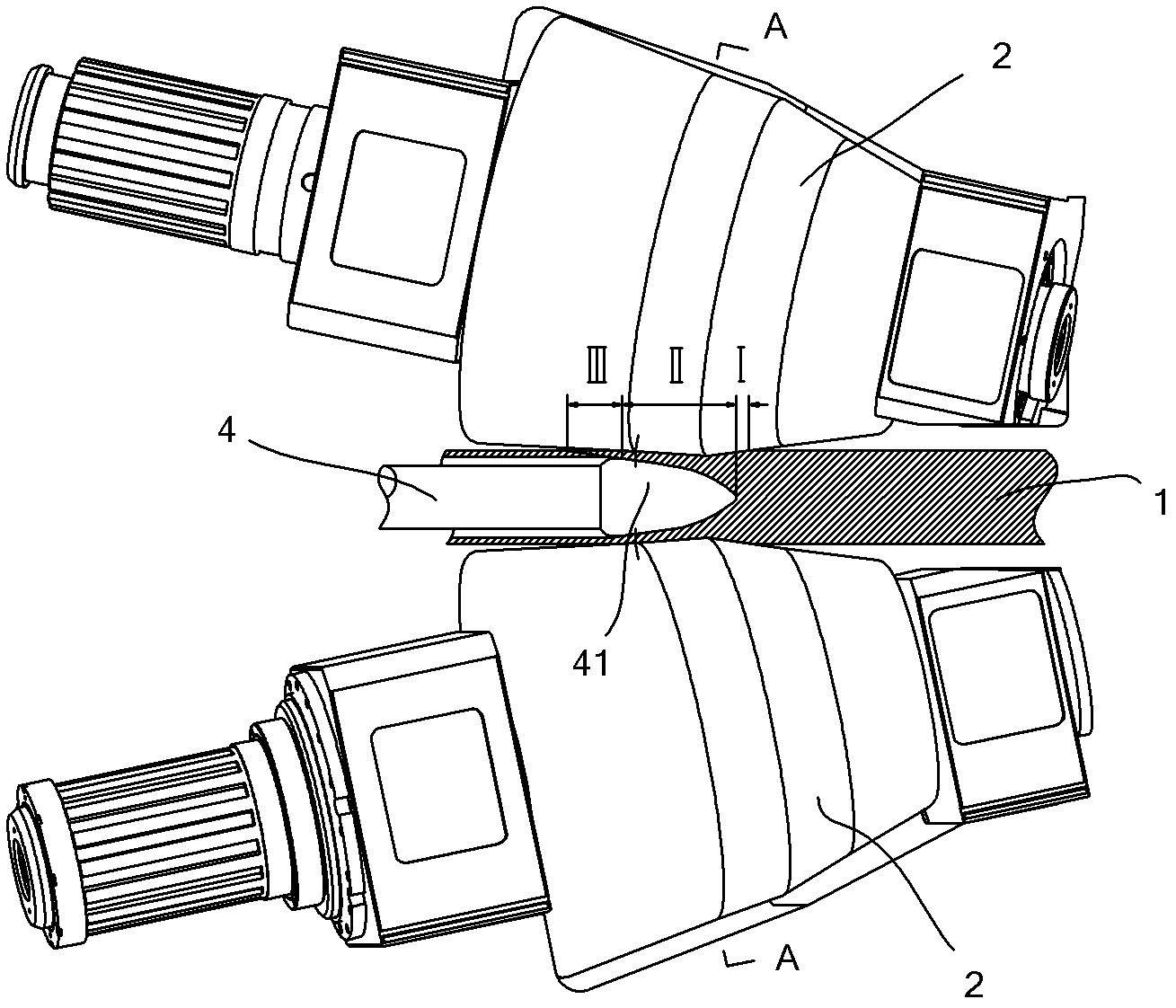

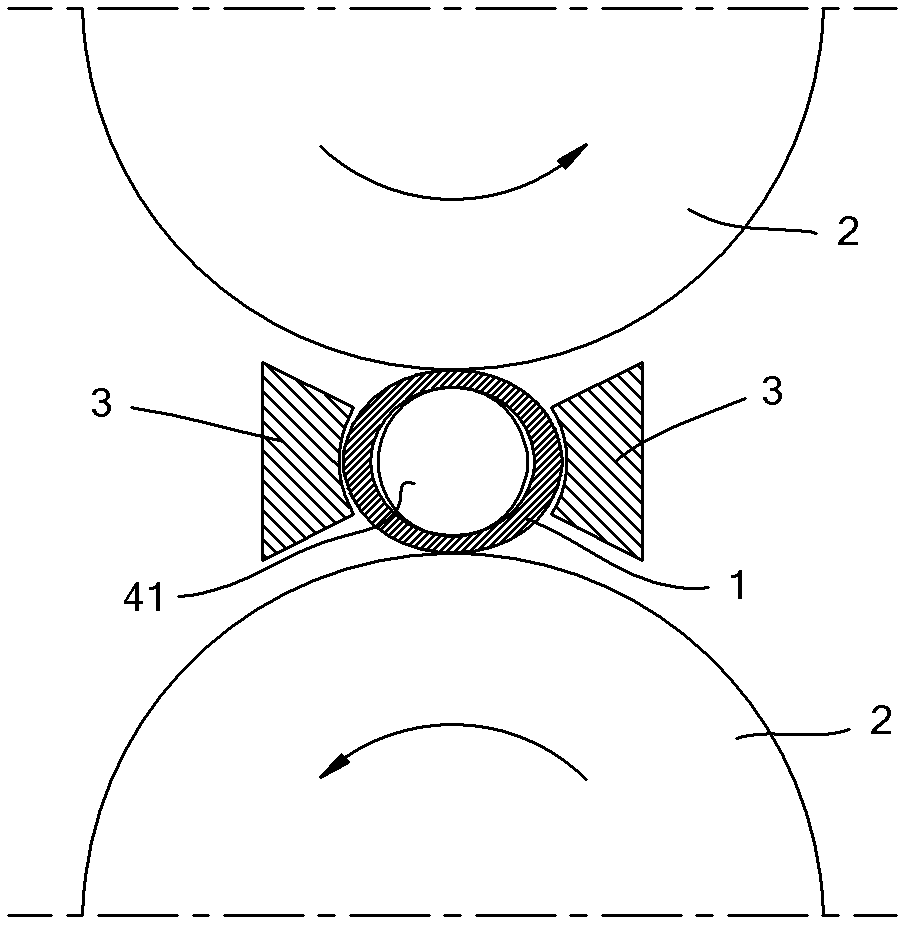

[0027] like figure 1 and figure 2 As shown, the piercing process of the tube blank 1 includes the tube blank 1, two left and right rollers 2 arranged obliquely relative to the rolling line, two upper and lower fixed guide plates 3, and a plug 41 of a moving ejector rod 4 in the middle. The action process of the blank tube 1, the roll 2 and the guide plate 3 has been discussed in detail in the background technology section, and will not be repeated here.

[0028] like image 3 and Figure 4 As shown, the present invention includes a push rod 4, a push rod tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com