Method for cleaning electromagnetic valve after thermal condition calibration of double-component thrustor

A dual-component thruster and solenoid valve technology, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of poor channel cleaning effect, no public use of cleaning technology and literature reports, etc., to reduce the number of disassembly and assembly , Enhance international business competitiveness and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

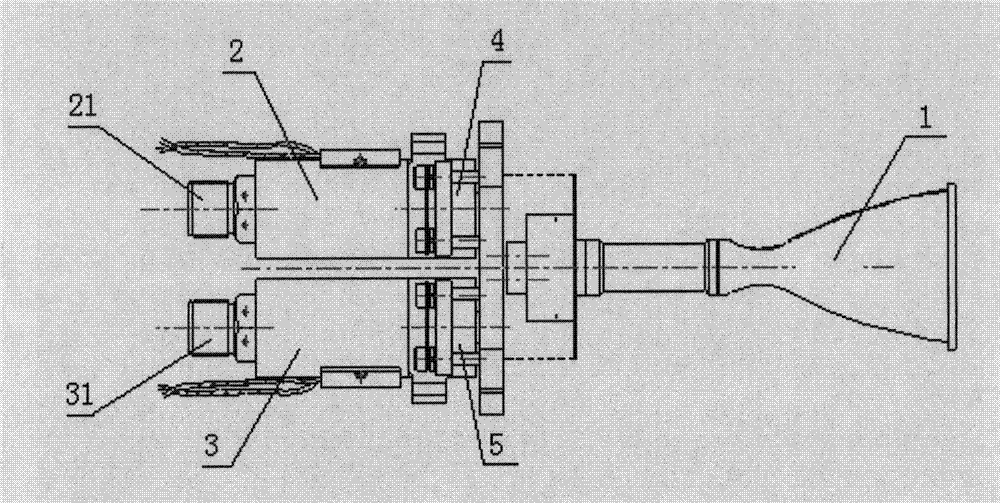

[0030] Such as figure 1 It is an overall schematic diagram of a dual-component thruster, in which thrust chamber 1, fuel circuit solenoid valve 2, oxygen circuit solenoid valve 3, fuel circuit solenoid valve inlet 21, oxygen circuit solenoid valve inlet 31, thruster combustion circuit inlet 4, thruster Oxygen road inlet 5.

[0031] The cleaning method of the electromagnetic valve after the heat-marking of the dual-component thruster of the present invention comprises the following steps:

[0032] The first step is to clean the thruster as a whole; the second step is to pulse flush the thruster fuel circuit with cleaning agent at the inlet 4 of the thruster fuel circuit; the third step is to use high-purity nitrogen at the inlet 4 of the thruster fuel circuit to Pulse flushing of the fuel circuit of the thruster: Step 4, use F113 to perform pulse cleaning of the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com