Particle image velocimetry (PIV) experimental particle mixing device based on pneumatic lug technology

A blender and tab technology, applied in the field of PIV experimental particle blender, can solve problems such as large flow total pressure loss, and achieve the effects of increasing entrainment capacity, good blending effect, and changing aerodynamic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

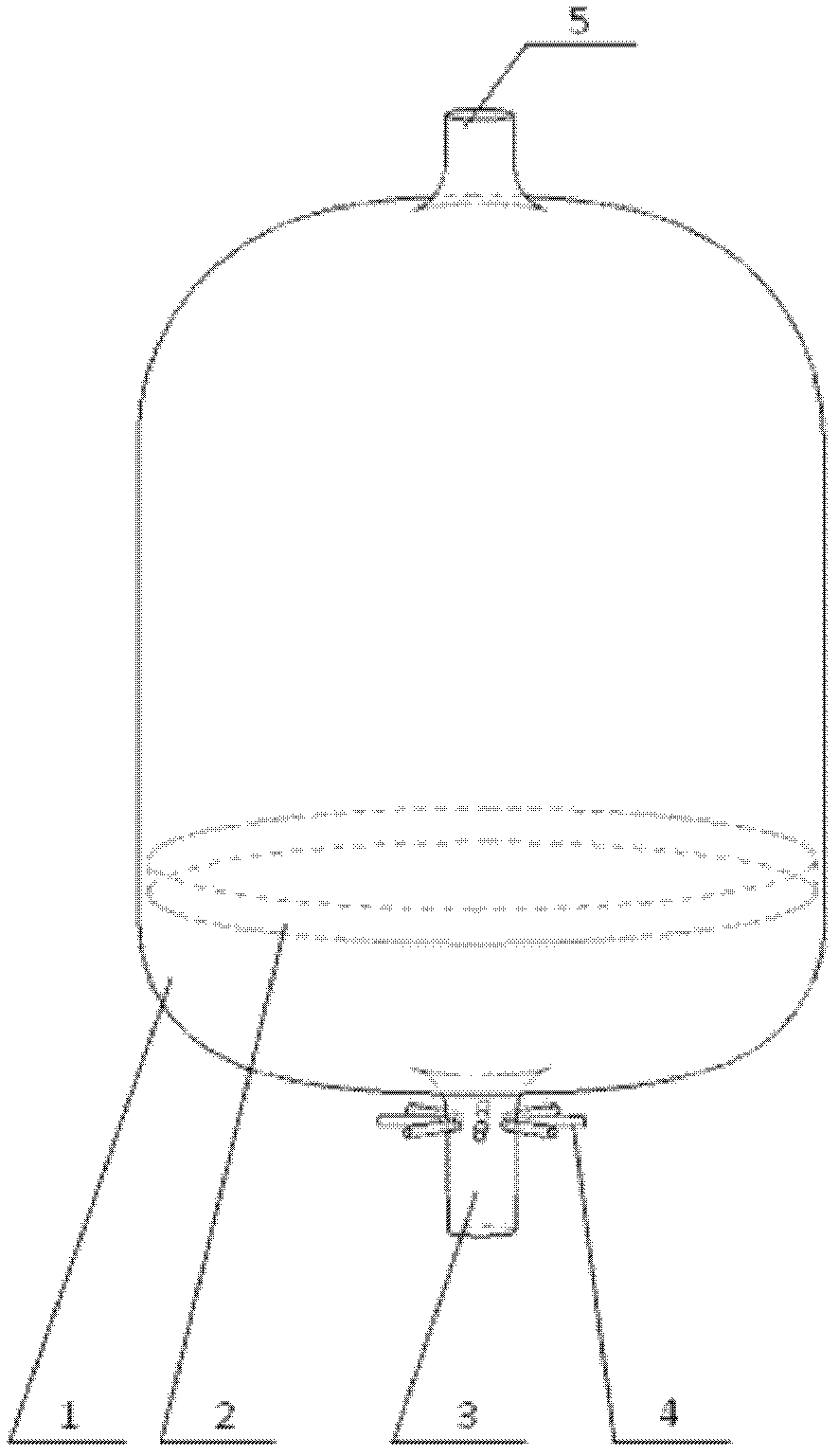

[0015] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the utility model; the technical solution of the utility model will be described in detail below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, it discloses the PIV experimental particle blender based on the pneumatic tab technology of the present invention, including a blending tank 1, a filter disc 2, an air intake manifold 3, a pneumatic tab 4, and an air outlet pipe 5. The pneumatic tab 4 consists of a pneumatic tab nozzle and a jet flow control mechanism. The pneumatic protruding nozzles are arranged circumferentially around the intake manifold, and the number is selected according to the diameter of the intake manifold and the mixing effect, generally less than 8. The shape of the injection port of the pneumatic protruding nozzles can be circular, Ellipse, rectangle or any polygon. The axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com