Nano powder slurry settling tank

A technology of nano-powder and settling tank, applied in the field of powder slurry settling tank, nano-powder slurry settling tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

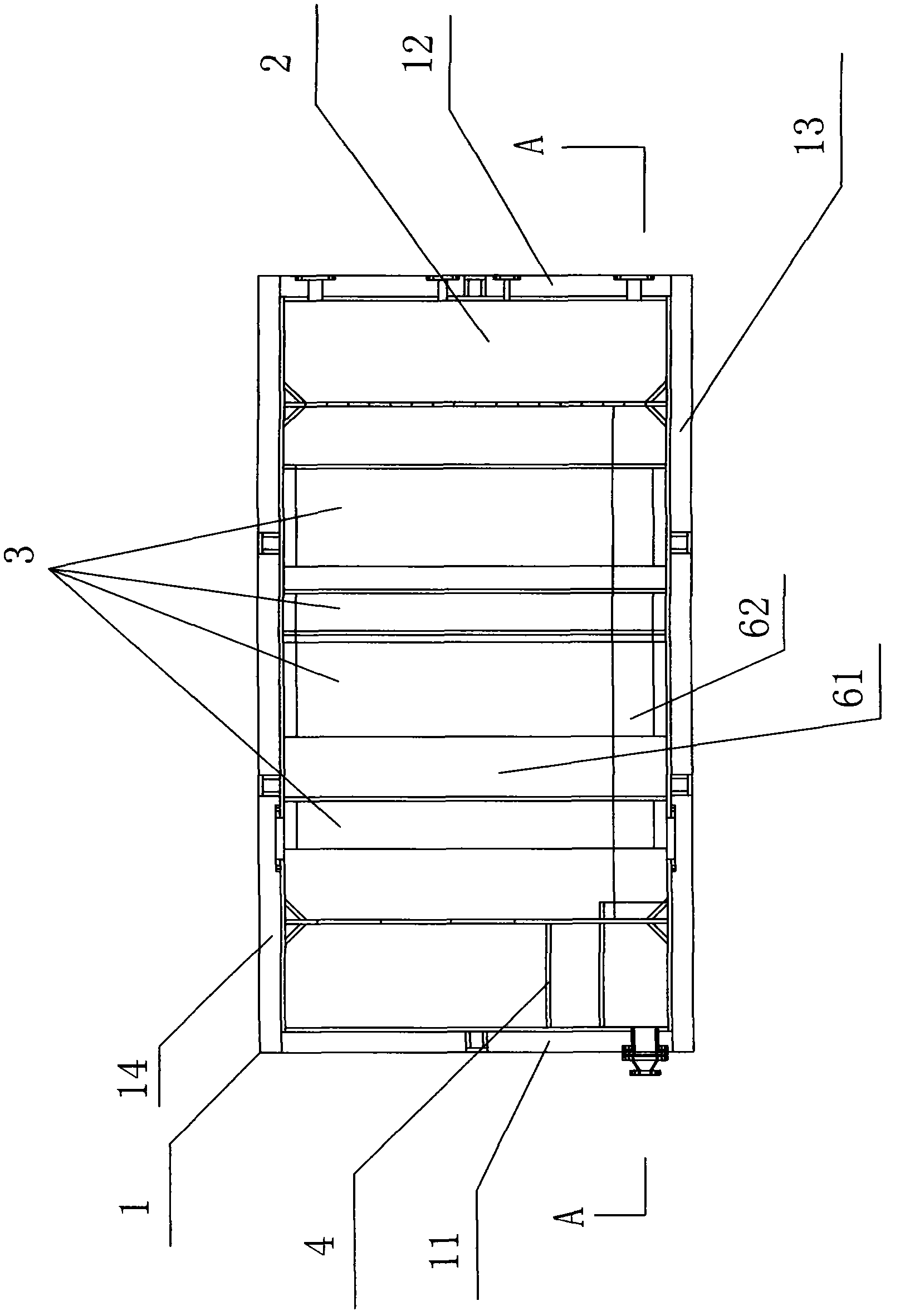

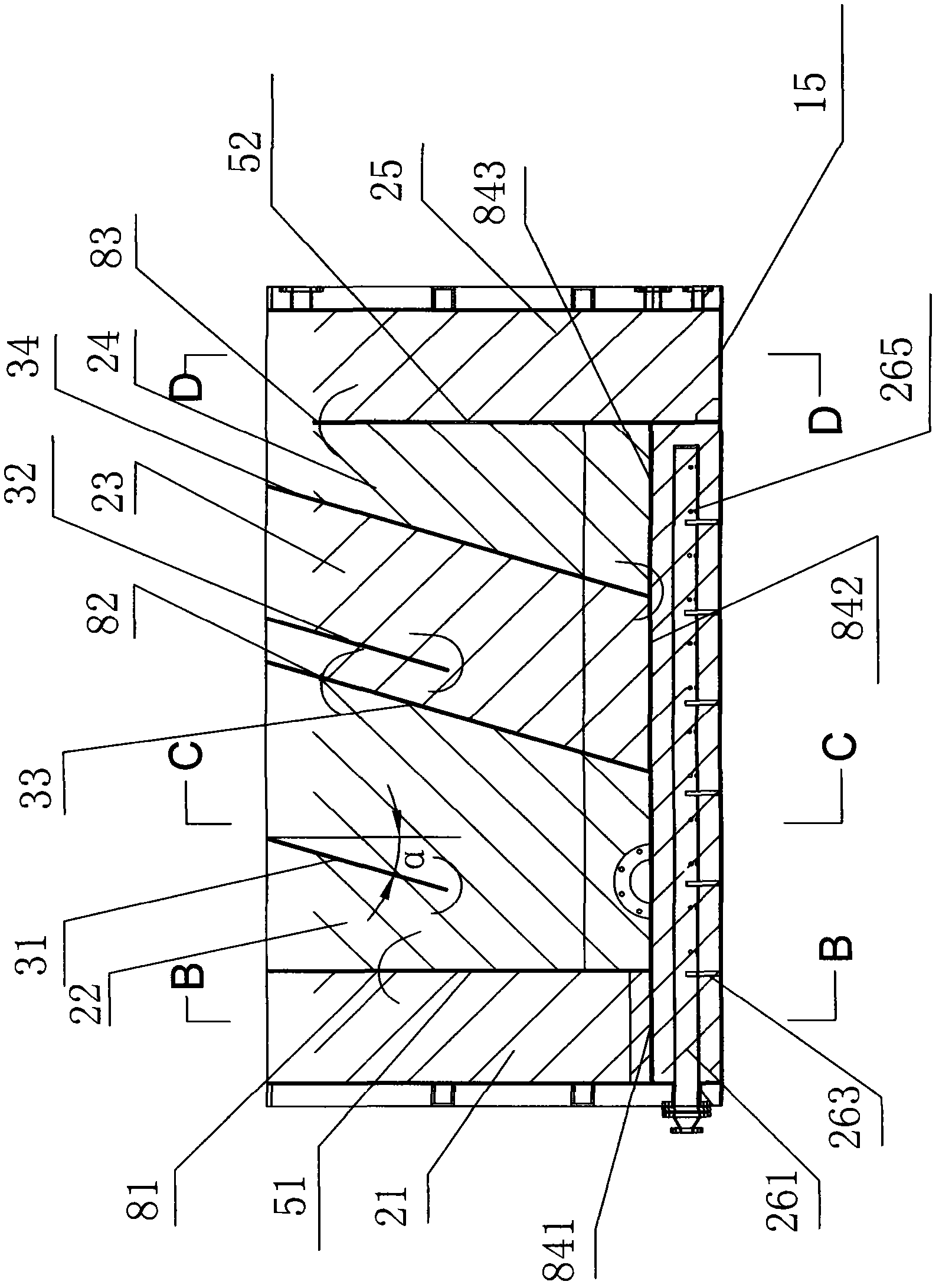

[0045] In the silo between the left and right side plates 11, 12, the overflow plate 51 of the feeding silo, the short inclined plate 31 on the settlement silo, the long slant plate 33 on the settlement silo, the short slant plate on the baffle silo The inclined plate 32, the long inclined plate 34 on the baffle hopper, and the overflow plate 52 of the overflow hopper are arranged in sequence from left to right, and the two sides of the above-mentioned plates are fixed to the front and rear side plates 13, 14 of the trough 1 connect;

[0046] The short partition plate 4 of the feed bin 21 is arranged vertically to the left side plate 11 in the middle and upper part of the feed bin 21. Set in the vertical direction, the short slant plate 31 on the settling hopper, the long slant plate 33 on the settling hopper, the short slant plate 32 on the baffle hopper and the long slant plate 34 on the baffle hopper are arranged obliquely from right to left; The supporting ribs 7 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com