Preparation method of porous three-dimensional silk fibroin material

A technology of silk fibroin and porous materials, which can be used in medical science, prosthesis, etc., can solve the problems of negative effects of biocompatibility, small pore size, and uncontrollable protein nanocrystalline structure, and achieves no toxic side effects and good pore formation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

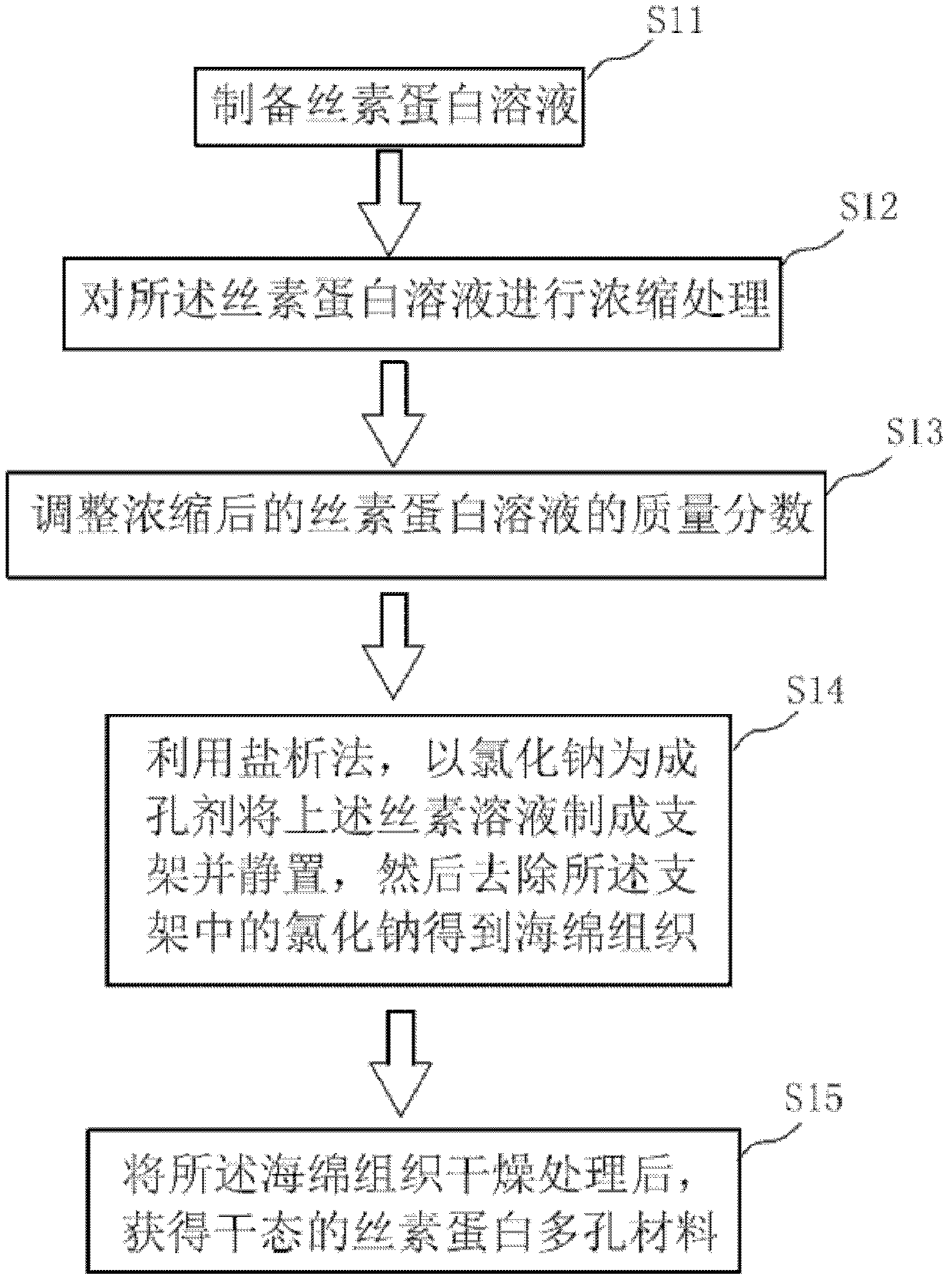

[0039] See figure 1 , figure 1 It is a flowchart of a method for preparing a silk fibroin porous three-dimensional material of the present invention. As shown in the figure, the preparation method includes steps:

[0040] S11: Prepare a silk fibroin solution, the silk fibroin solution has a first concentration;

[0041] S12: Concentrating the silk fibroin solution to make the silk fibroin solution have a second concentration, and the second concentration is greater than the first concentration;

[0042] S13: adjusting the mass fraction of the concentrated silk fibroin solution so that the mass fraction of the silk fibroin solution is 4% to 9%;

[0043] S14: Using a salting-out method, using sodium chloride as a pore-forming agent, the above silk fibroin solution is made into a scaffold and allowed to stand, and then the sodium chloride in the scaffold is removed to obtain a spongy tissue;

[0044] S15: After drying the spongy tissue, a dry silk fibroin porous material is ob...

Embodiment 1

[0052] Prepare silk fibroin solution. Specifically: put 50g silk into 0.5% Na 2 CO 3 Degumming was carried out in the solution and dried. During degumming, the silk was boiled at 100°C for 1 hour to remove sericin on the outside of the silk, rinsed with deionized water, and the above operation was repeated 3 times, and then the silk was dried at 60°C. Weigh 15 g of the degummed silk after the above treatment and put it into 100 mL of lithium bromide (LiBr) solution with a concentration of 9.3 mol / L for dissolving treatment, and dissolve at 60° C. for 4 hours during the dissolving treatment. Then above-mentioned LiBr solution that is dissolved with silk is carried out dialysis treatment, during dialysis, with the dialysis bag of molecular weight cut-off 3500, soak in deionized water and dialyze for 3 days, change water once every two hours during the period, to remove LiBr in the solution, thereby obtain pure Silk fibroin solution, its concentration is 6%.

[0053] The above...

Embodiment 2

[0058] A pure silk fibroin solution with a concentration of 6% was prepared by the same method as in Example 1.

[0059] The silk fibroin solution was concentrated at 80° C. for 8 hours, and the concentrated silk fibroin solution had a concentration of 20%. Then the massfraction of silk fibroin aqueous solution is adjusted to 4%;

[0060] The silk fibroin solution was salted out to make a scaffold, and after standing for 48 hours, it was soaked in water for 72 hours to remove NaCl and obtain a spongy tissue.

[0061] The nano silk protein porous material is obtained after natural drying at room temperature by adopting a slow drying treatment method.

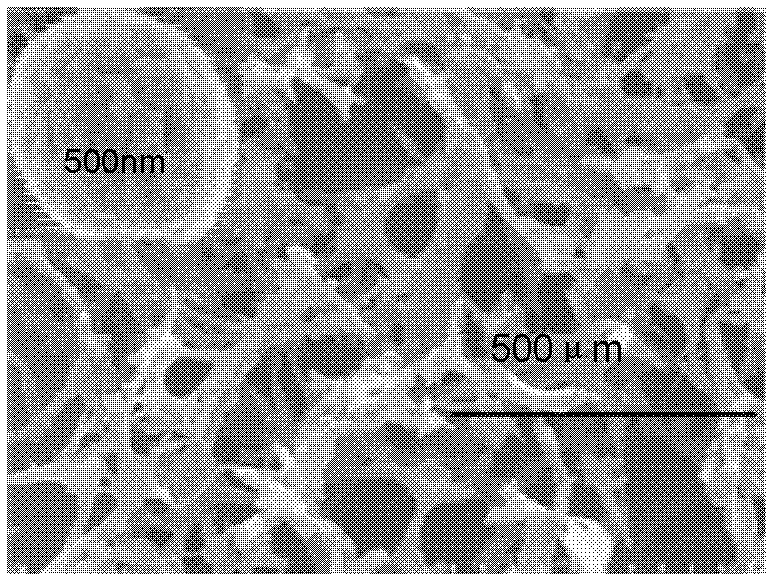

[0062] See image 3 , image 3 It is the scanning electron microscope test of the above-mentioned silk fibroin scaffold in embodiment two. It was found that the pore size of the scaffold was about 319±15 μm, and the hardness was increased compared with the vacuum-dried scaffold with the same pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com