diving rig

A technology for submersible drilling rigs and drill pipes, which is applied to rotary drilling rigs, drilling equipment, earthwork drilling, etc., and can solve the problems of poor hole verticality, large hole expansion coefficient, and low speed, and achieve good hole-forming effects and large-scale expansion. The effect of small hole coefficient and high output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

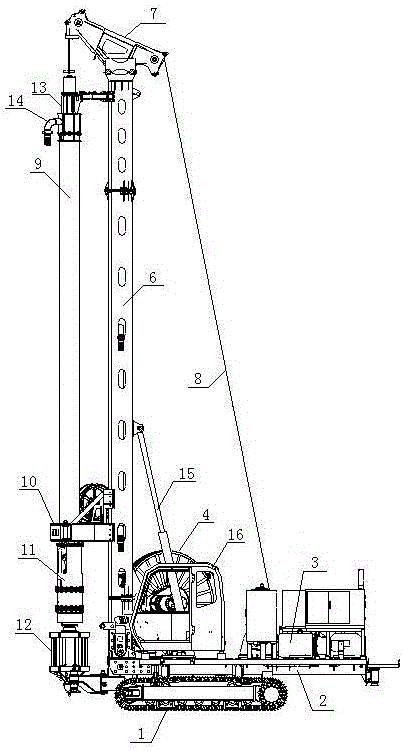

[0019] Such as figure 1 , figure 2 Shown, a kind of submersible drilling rig, it comprises walking mechanism 1, the platform 2 erected on the top of traveling mechanism, erected on the platform: power source 3, electric / hydraulic pipeline, capstan machine 4, winch 5, mast 6, erected on The crown block 7 at the top of the mast 6, the drill pipe 9 hoisted on the mast 6 through the steel wire rope 8 and the crown block 7, and the guide frame 10 slidingly connected with the mast 6, the guide frame 10 encircles and clamps the drill pipe 9, and is arranged on The submersible power head 11 and the drill bit 12 on the drilling rod 9; also include the steel wire rope sealing rotary joint 13, the mud transition joint 14 and the winch synchronization mechanism; the drilling rod 9 is retractable and its inside is hollow, specifically, the drilling rod 9 It is composed of multi-section tubular rod bodies t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com