Dry granulation method for cold and cough relieving capsules

A dry granulation, cold and cough relieving technology, applied in the directions of capsule delivery, pharmaceutical formulation, drug delivery, etc., can solve the problems of reduced content of medicinal components, unstable product quality, high production cost, etc., achieves short operation time, is beneficial to The effect of labor protection and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

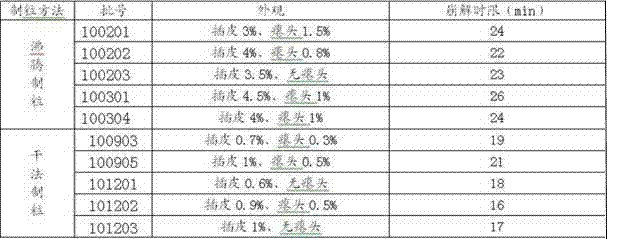

Examples

Embodiment

[0052] A dry granulation method for cold cough capsules, comprising the steps of:

[0053] (1) The preparation method of the spray powder is: take the extract and spray-dry it. The air inlet temperature of the spray drying is required to be 195±5°C, the air outlet temperature to be 105±5°C, and the spray frequency to be 10-16HZ to obtain the spray powder.

[0054] (2) Adjust the process parameters of the dry granulator: the pressure of the hydraulic system is 13-14 MPa, the speed of the main machine is ≤21 Hz, the horizontal feeding frequency is 12-18 Hz, the vertical feeding frequency is 9-15 Hz, crushed through a 20-mesh sieve; weigh the spray powder and The menthol inclusion complex was mixed by equal increment method, and then mixed for 10 minutes to discharge, and then granulated by dry granulator, and the obtained granules were dried at 95±5°C for 30 minutes, then cooled to below 40°C and discharged. Mixing: The obtained dry granules are mixed with magnesium stearate for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com