Pneumatic bucket wheel type precision corn seeder

A technology of seed metering device and seed metering device cover, which is applied in the direction of seeder parts, etc., can solve the problems of missed sowing, high power consumption, and poor adaptability of seed shape, etc., and achieve reduced power consumption, elimination of missed sowing, and good seed filling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

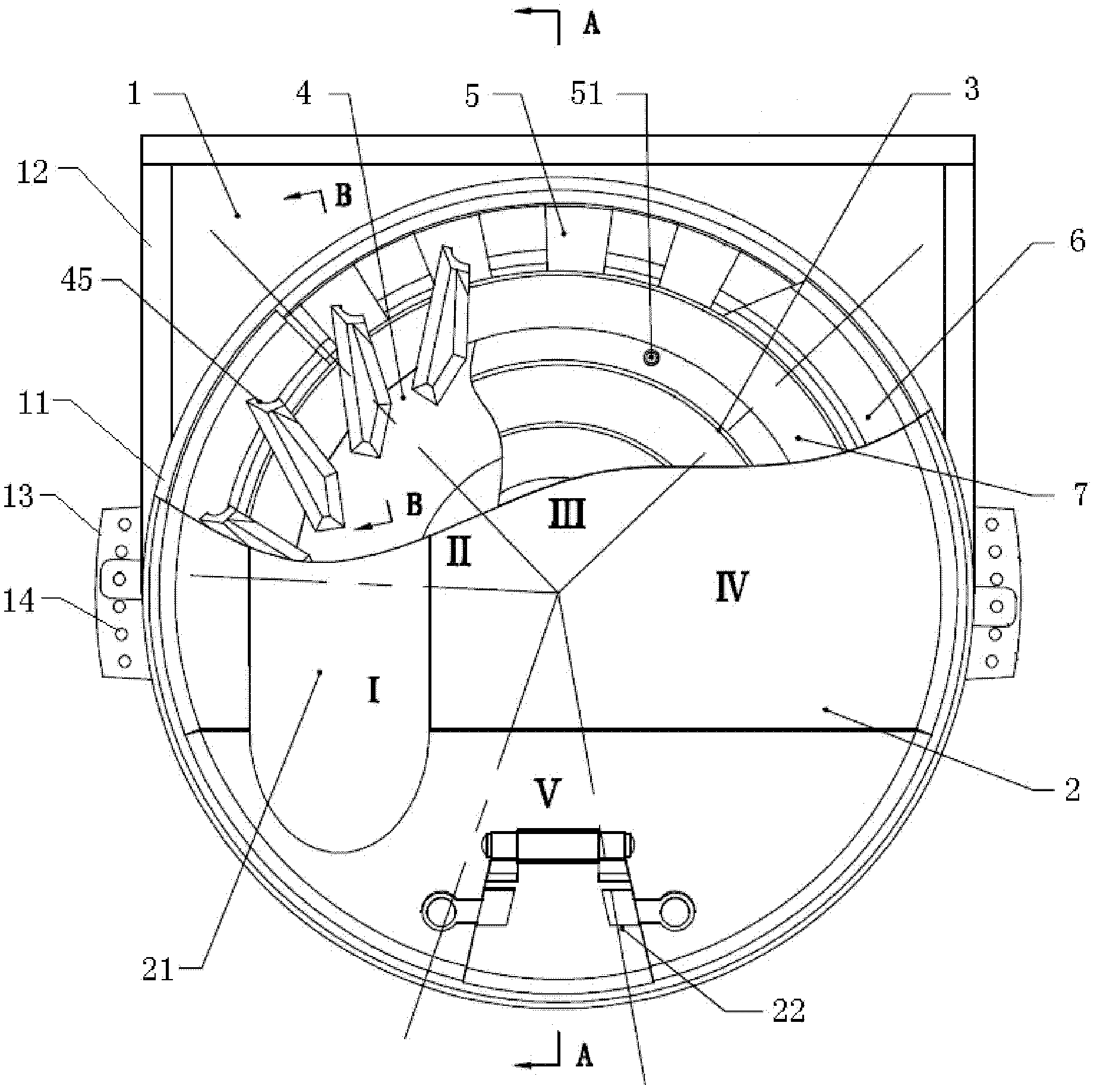

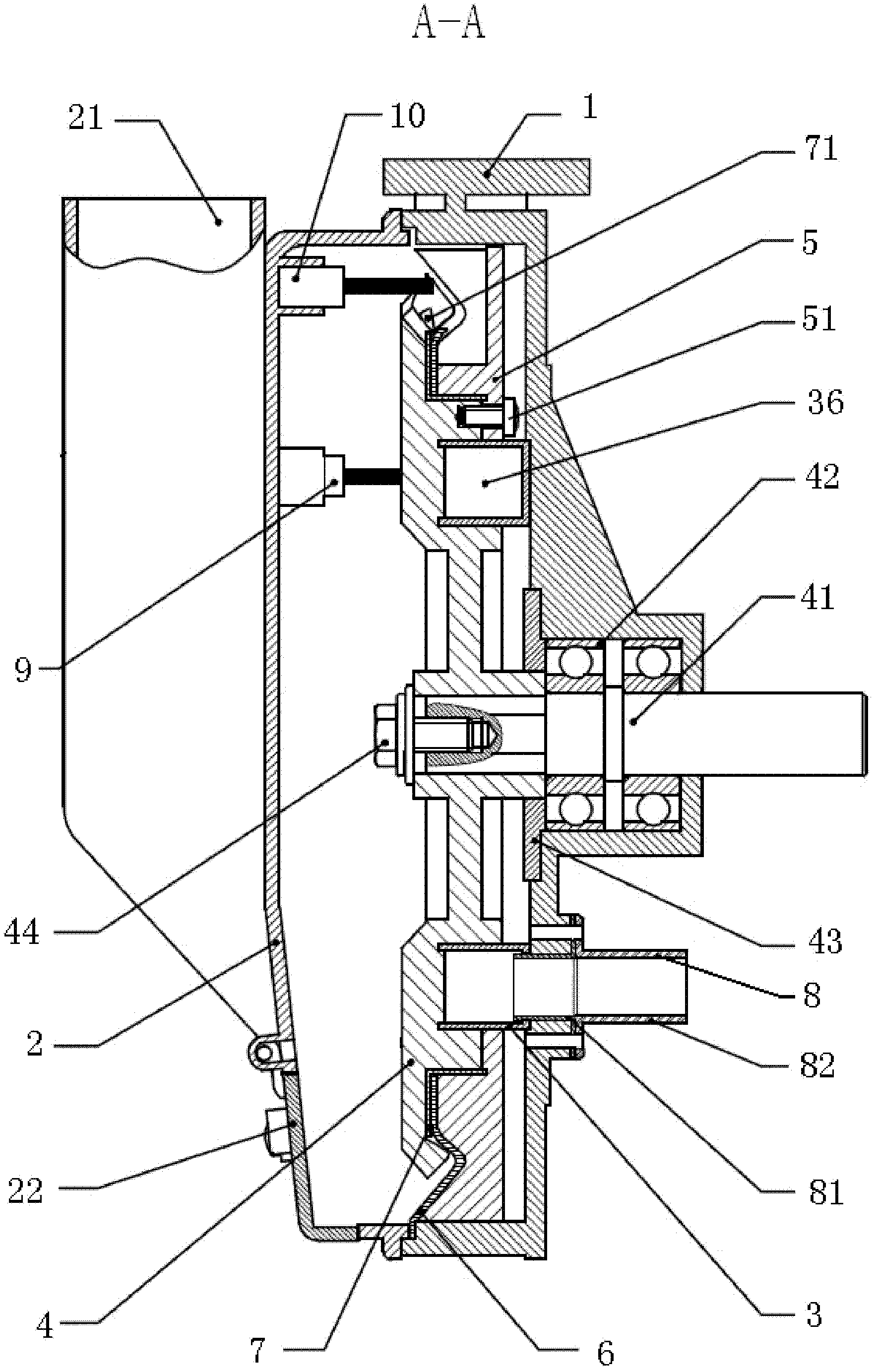

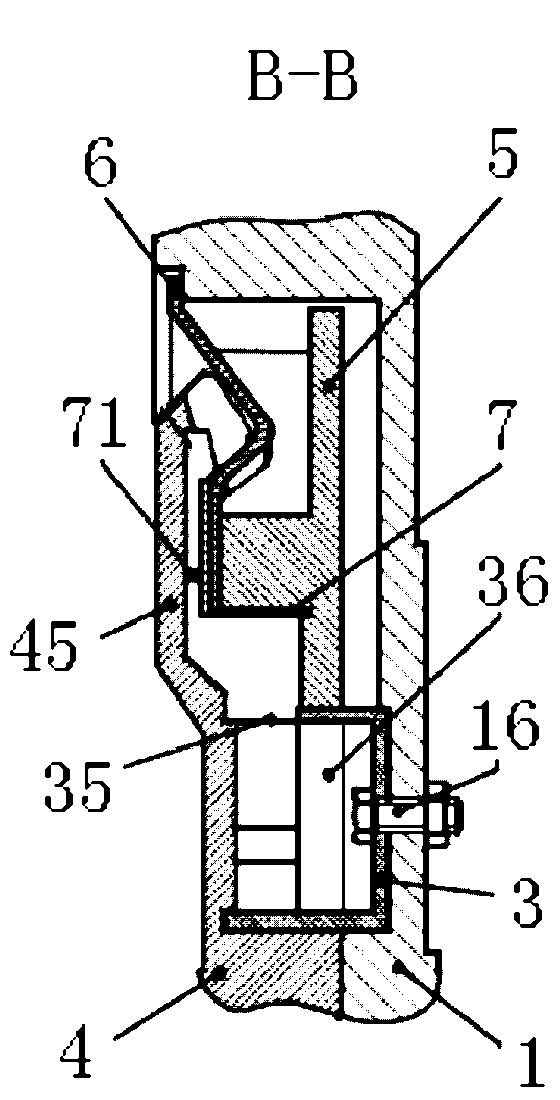

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] Such as Figure 1~5 As shown, the present invention includes a seed metering device housing 1, a seed metering device cover plate 2, a suction chamber housing 3, a seed metering disc 4, a seed guide impeller 5, a partition 6, a wear-reducing sealing ring 7 and an air nozzle 8 . The seed meter housing 1 and the seed meter cover plate 2 are fixedly snapped together to form a circular chamber, the suction chamber housing 3, the seed metering disc 4, the seed guiding impeller 5, the partition 6 and the wear-reducing sealing ring 7 set in the circular chamber.

[0020] The seed meter housing 1 includes an open circular cavity 11 made of circular steel plates, and a square body 12 is arranged on the top of the circular cavity 11 for easy hoisting. Both sides of the seed meter housing 1 are respectively provided with an adjusting plate 13, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com