Waterproof electric connector assembly

A technology of electrical connectors and components, which is applied to parts, connections, electrical components, etc. of connection devices, can solve problems such as electromagnetic leakage and poor shielding performance of mating ends, and achieve the effect of sealing that is not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

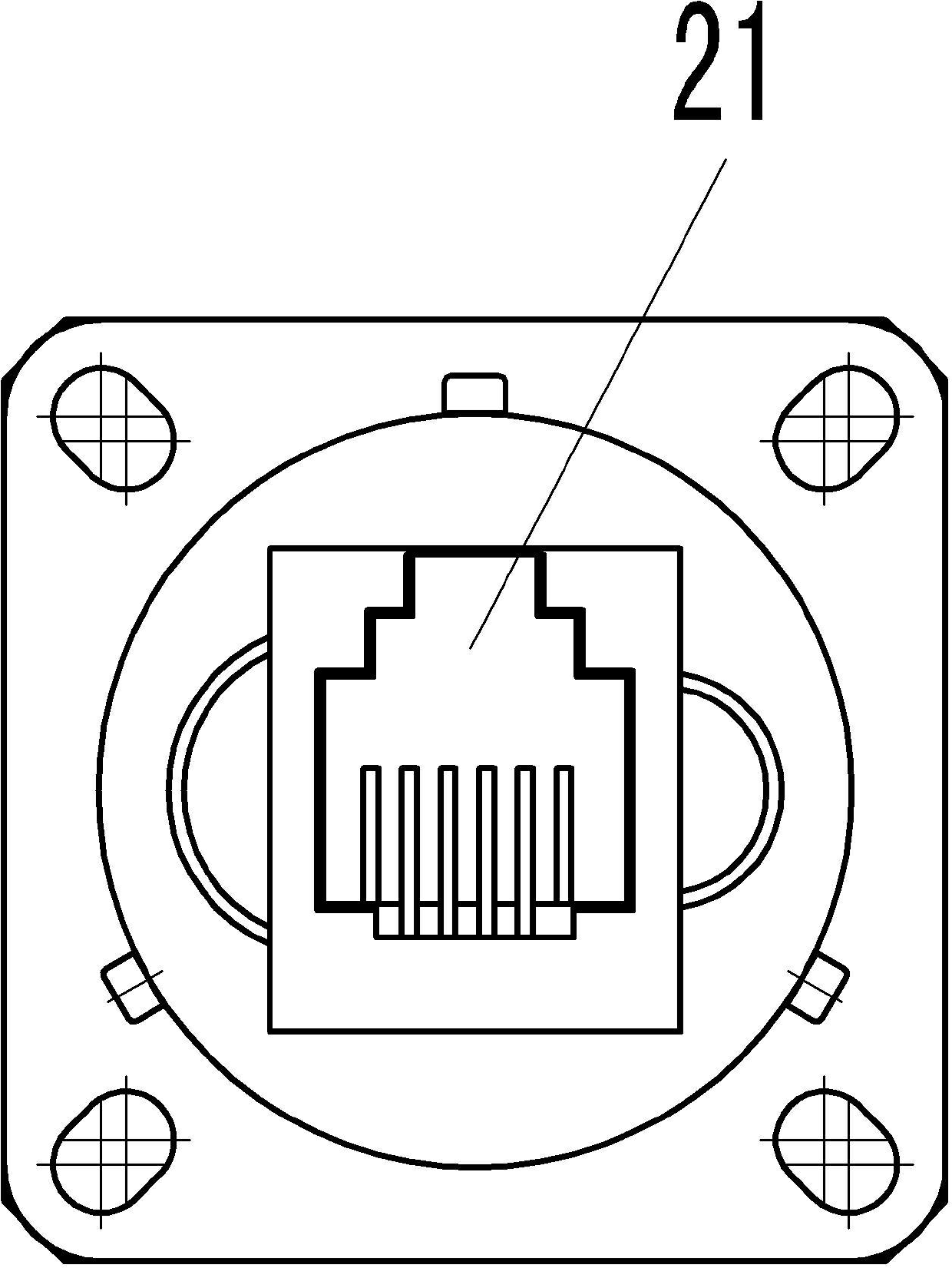

[0020] Such as Figure 5~Figure 8 As shown, the embodiment of the waterproof electrical connector assembly of the present invention includes a plug 3 and a socket 4 that are mated with each other at their front ends. The plug 3 includes a plug housing 30 with a male RJ-45 interface 32 inside. The front end of the plug housing 30 is integrally provided with a sleeve-shaped intubation body 31 surrounding the male RJ-45 interface 32. The socket 4 includes an inner A socket housing 40 with a female RJ-45 interface 42 is provided. The front end of the socket housing 40 has an inserting column body 41 that is inserted into the intubation body 31 of the plug 3 so that the male and female RJ-45 interfaces are mated. .

[0021] The outer periphery of the socket housing 40 is sealed and fixed with a locking sleeve 43 , and a sealing ring 49 is provided between the rear of the socket housing 40 and the rear of the locking sleeve 43 . There is an insertion gap 48 for the intubation body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com