Partial discharge detection pulse current sensor with self correcting function

A technology of partial discharge detection and pulse current, which is applied in the direction of testing dielectric strength, etc., can solve the problems of being unable to judge whether it is still in normal working condition, troublesome equipment operation, and inconvenient calibration of sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

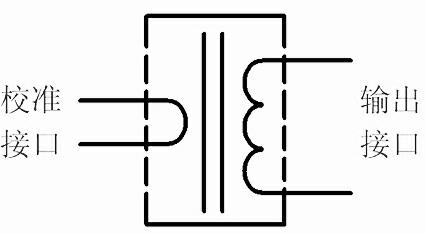

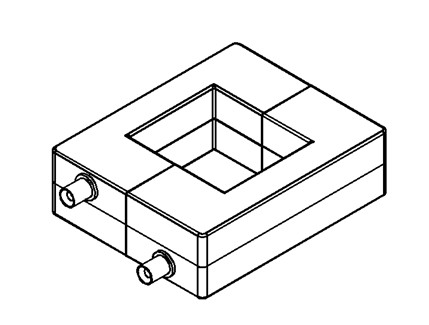

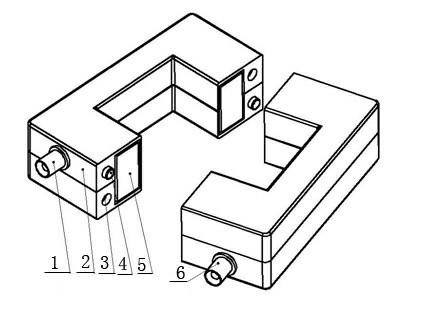

[0018] Partial discharge detection pulse current sensor with self-calibration function, the closed-loop magnetic core 5, output coil and calibration coil are arranged in the shell, and the partial discharge detection is carried out by inducing the current flowing through the magnetic core through the output coil wound on the closed-loop magnetic core. A calibration coil is added to the magnetic core to realize self-calibration and self-test functions, and a calibration interface 1 and an output interface 6 are provided, the calibration interface is connected to the calibration coil, and the output interface is connected to the output coil.

[0019] Said casing has various structures, including: the casing is an open rectangular structure or a closed circular structure, which is suitable for partial on-line inspection or partial on-line monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com