Temperature measuring device and method with calibration function

A temperature measuring device and a function technology, applied in the field of temperature measuring devices with calibration function, can solve the problems of complicated operation and low efficiency, and achieve the effect of high temperature measuring accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

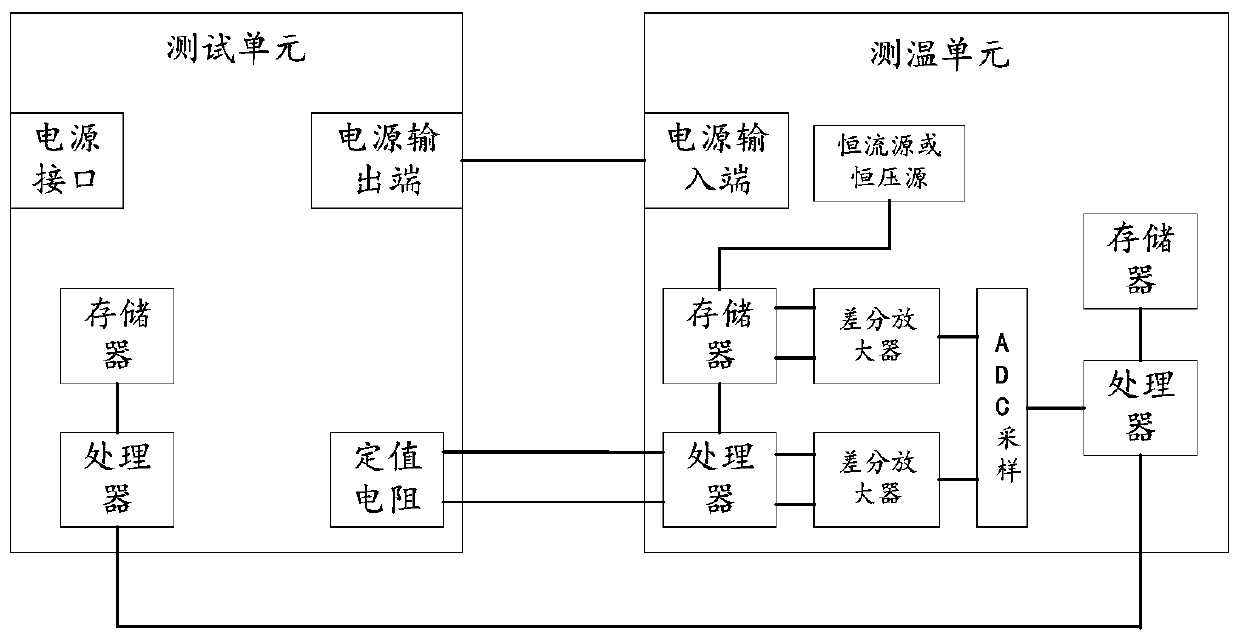

[0035] figure 1 Schematically provides a simplified structure diagram of the temperature measuring device with calibration function in Embodiment 1 of the present invention, as figure 1 As shown, the temperature measuring device with calibration function includes:

[0036] A test unit, the test unit includes:

[0037] A fixed-value resistor, the fixed-value resistor has a connection terminal and is suitable for being connected in series with a proportional resistor;

[0038] a first memory, the first memory is used to store the data transmitted from the temperature measurement unit and the result of the first processor;

[0039] a first processor, the first processor processes the data sent by the temperature measurement unit;

[0040] a power interface, the output end of the power interface is connected to the first memory and the first processor;

[0041] a power supply output terminal, the power supply output terminal is arranged on the test unit and communicated with t...

Embodiment 2

[0058] An application example of the temperature measuring device and method with calibration function according to Embodiment 1 of the present invention.

[0059] In this application example, the precision of the proportional resistor is 0.1%, and the resistance value is 1KΩ; the temperature measuring resistor adopts PT1000; both the first voltage detection module and the second voltage detection module include a differential amplifier and an ADC sampler (shared), and the second The processor processes the electrical signal delivered by the ADC sampler.

[0060] The temperature measurement method of the embodiment of the present invention, that is, the working process of the temperature measurement device with calibration function according to the embodiment of the present invention, the temperature measurement method includes the following steps:

[0061] (A1) Establish communication between the test unit and the temperature measurement unit;

[0062]The proportional resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com