Method for separating single peak from multi-peak chromatogram

A chromatogram, a separate technology, applied in the field of stripping out individual peaks, can solve the problems of cumbersome methods, many parameters, difficult to implement, etc., and achieve the effects of simple operation, high quantitative accuracy and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

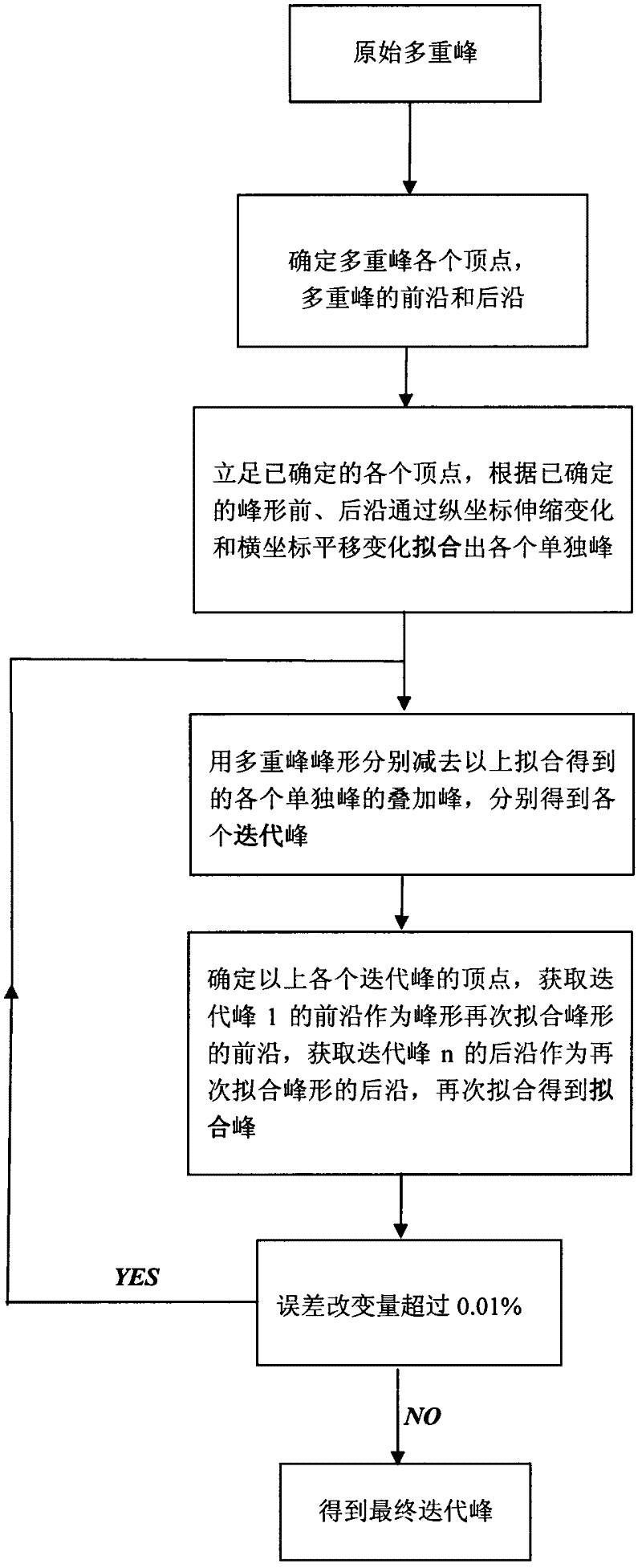

Method used

Image

Examples

Embodiment 1

[0038] Instruments: HP6890 gas chromatograph, hydrogen flame ionization detector, 6890 gas chromatograph workstation;

[0039] Chromatographic column: non-polar HP-5 (5% phenylmethylpolysiloxane) column, 30m×0.32mm×2.5μm;

[0040] Conditions: The temperature of the detector is 250C, the temperature of the injection port is 250C, and the temperature of the column is 80C;

[0041] Carrier gas: Use high-purity nitrogen gas (purity not less than 99.999%), constant flow operation mode, that is, the carrier gas is at the outlet of the column, and the mass flow rate is kept constant at 1ml / min;

[0042] Injection method: split injection, the split ratio is 50:1, each injection volume is 0.2ul,

[0043] Samples: methyl tert-butyl ether, benzyl alcohol, butyric and heptanoic acids.

[0044] In order to verify the method of the present invention, the chromatograms of the above four samples are artificially superimposed with different degrees of overlap by shifting the abscissa (ie ret...

Embodiment 2

[0071] Instruments: HP6890 gas chromatograph, hydrogen flame ionization detector, 6890 gas chromatograph workstation;

[0072] Chromatographic column: non-polar HP-5 (5% phenylmethylpolysiloxane) column, 30m×0.32mm×2.5μm;

[0073] Conditions: The detector temperature is 250°C, the inlet temperature is 250°C, and the column temperature is 200°C;

[0074] Carrier gas: use high-purity nitrogen gas (purity not less than 99.999%), constant flow operation mode, that is, the carrier gas is at the outlet of the column,

[0075] The mass flow rate is kept constant at 1ml / min;

[0076] Injection method: split injection, the split ratio is 50:1, the injection volume is 0.8ul,

[0077] Samples: Isoamyl Alcohol, 1,4-Dioxane, Butyl Acetate, and Isoamyl Acetate.

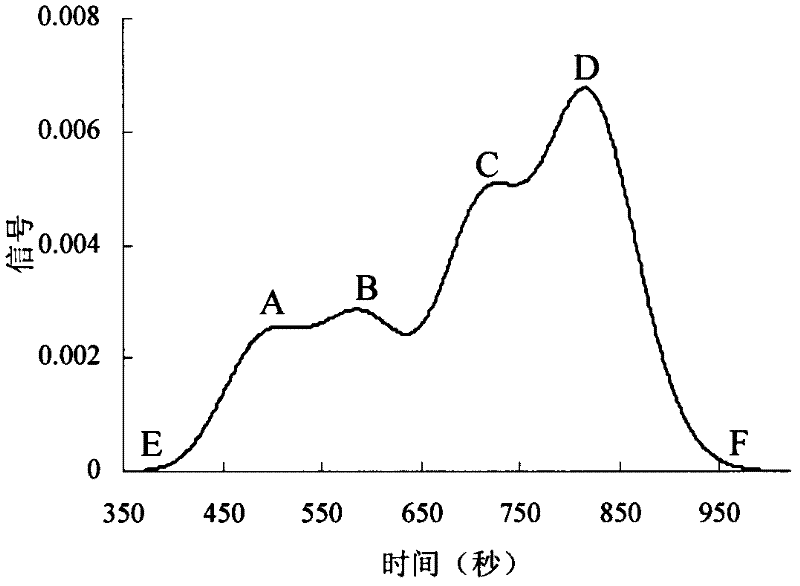

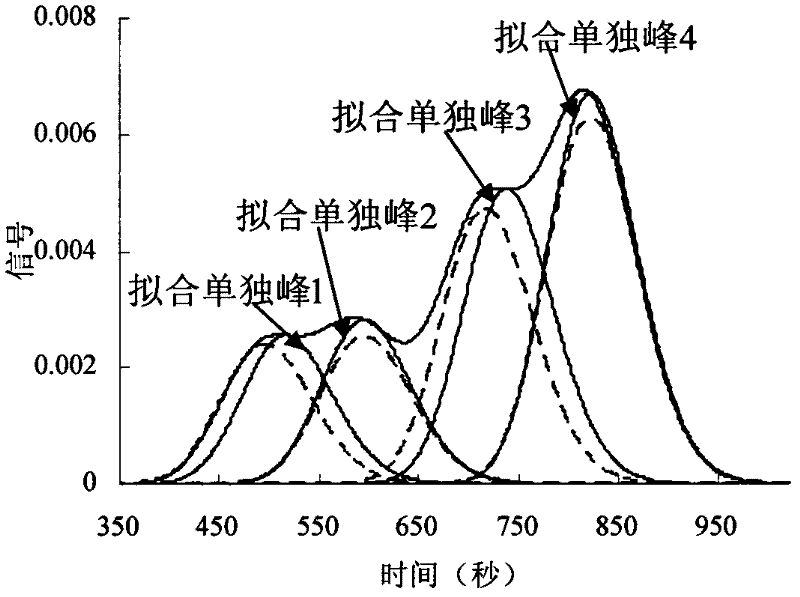

[0078] Resolution: 0.44, see Figure 8 and Figure 9 .

[0079] Quantitative results:

[0080] Quantitative error of the method of the present invention: isoamyl ester (-0.32%), 1,4-dioxane (-0.81%), butyl acetate (-0.32%), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com