Method for determining high-temperature movement viscosity of lubricating oil

A technology of kinematic viscosity and lubricating oil, applied in the measurement of DC flow characteristics, etc., can solve the problems of large measurement error and inability to meet user requirements, and achieve the effect of meeting development requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

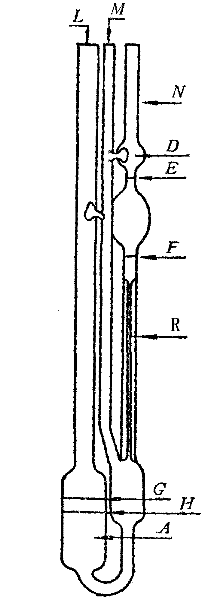

[0058] Embodiment 1: Determination of the kinematic viscosity of KXY aviation lubricating oil at 150°C

[0059] 1. Determine the appropriate Ubbelohde viscometer:

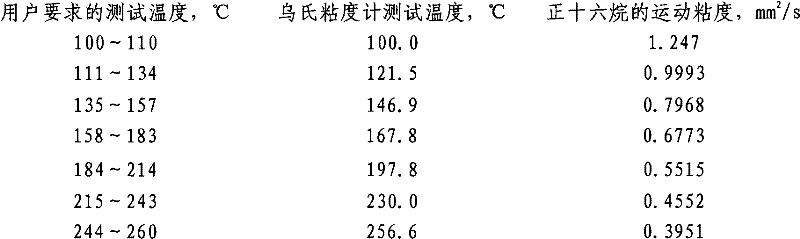

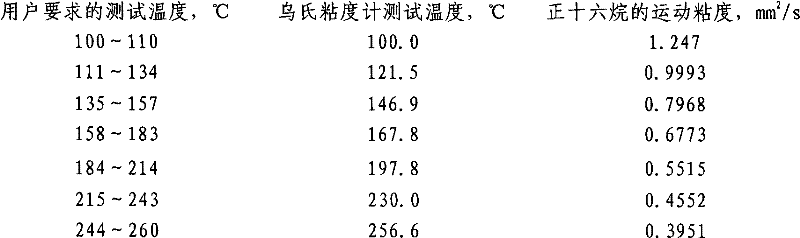

[0060] 1.1. Set the temperature of the constant temperature oil bath to 146.9°C, and the temperature control accuracy of the constant temperature oil bath is ±0.1°C;

[0061] 1.2. Select an Ubbelohde viscometer with a capillary diameter of 0.46 mm as the pre-selected Ubbelohde viscometer, numbered No. 1, and clean the No. 1 viscometer according to the cleaning method specified in Section 4.2 of the national standard GB / T 265 and dry it;

[0062] 1.3. Use n-hexadecane with a purity of 99% to measure the viscosity coefficient c of No. 1 viscometer;

[0063] 1.3.1. Fill the No. 1 viscometer with n-hexadecane: Tilt the No. 1 viscometer with the plumb line at 30°, pour enough n-hexadecane into the bottom storage ball A through the mounting tube L, and The amount of cetane should meet the following conditions: when the...

Embodiment 2

[0079] Embodiment 2: Determination of the kinematic viscosity of KXY aviation lubricating oil at 200°C

[0080] 1. Determine the appropriate Ubbelohde viscometer:

[0081] 1.1. Set the temperature of the constant temperature oil bath to 197.8°C, and the temperature control accuracy of the constant temperature oil bath is ±0.1°C;

[0082] 1.2. Select an Ubbelohde viscometer with a capillary diameter of 0.36 mm as the pre-selected Ubbelohde viscometer, numbered No. 2, and clean the No. 2 viscometer according to the cleaning method specified in Section 4.2 of the national standard GB / T 265 and dry it;

[0083] 1.3. Use n-hexadecane with a purity of 99% to measure the viscosity coefficient c of No. 2 viscometer;

[0084] 1.3.1. Fill the No. 2 viscometer with n-hexadecane: Tilt the No. 2 viscometer with the plumb line at 30°, pour enough n-hexadecane into the bottom storage ball A through the mounting tube L, and The amount of cetane should meet the following conditions: when the...

Embodiment 3

[0100] Embodiment 3: Determination of the kinematic viscosity of KXY aviation lubricating oil at 260°C

[0101] 1. Determine the appropriate Ubbelohde viscometer:

[0102] 1.1. Set the temperature of the constant temperature oil bath to 256.6°C, and the temperature control accuracy of the constant temperature oil bath is ±0.1°C;

[0103] 1.2. Select an Ubbelohde viscometer with a capillary diameter of 0.24 mm as the pre-selected Ubbelohde viscometer, numbered No. 3, and clean the No. 3 viscometer according to the cleaning method specified in Section 4.2 of the national standard GB / T 265 and dry it;

[0104] 1.3. Use n-hexadecane with a purity of 99% to measure the viscosity coefficient c of No. 3 viscometer;

[0105] 1.3.1. Fill the No. 3 viscometer with n-hexadecane: Tilt the No. 3 viscometer with the plumb line at 30°, pour enough n-hexadecane into the bottom storage ball A through the mounting tube L, and The amount of cetane should meet the following conditions: when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com