Portable rail welding joint medium-to-high-frequency electric induction heating normalizing device and method

A technology of welding joints and induction heating, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems affecting the quality of normalizing, joint quality, heating temperature that is difficult to control, and cannot be eliminated in time, so as to achieve controllable heat-affected area, The effect of short temperature rise time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

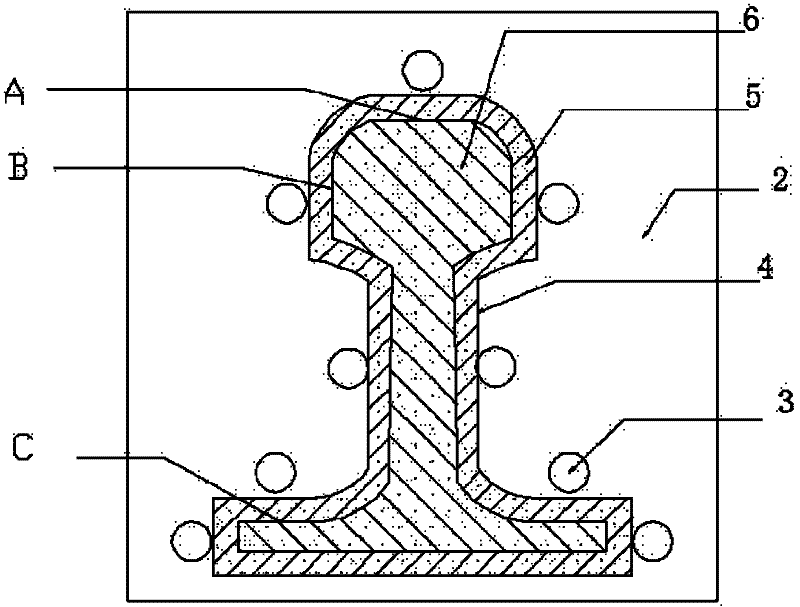

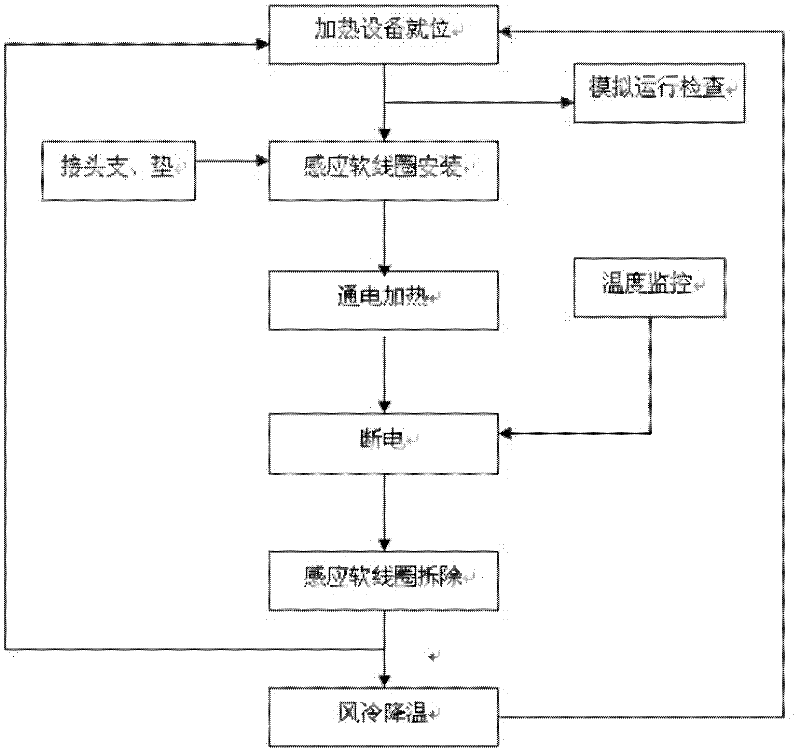

[0045] like image 3 As shown, after the on-site rail welding is completed, the normalizing heating equipment is placed at the rail welding joint. After the normalizing equipment simulates the operation and checks that it is normal, the rail joint is supported and cushioned to keep the rail in the design line shape, and then the induction soft coil is installed. At the joint position, turn on the frequency conversion oscillating power supply, conduct medium and high frequency induction heating for 6 to 8 minutes, measure the temperature of the rail surface with an infrared probe, and when the temperature of the heated rail reaches 800°C to 950°C, the temperature control device will control the switch to automatically disconnect Heat the power supply, then remove the induction soft coil, and use air cooling to cool down the normalized rail joint.

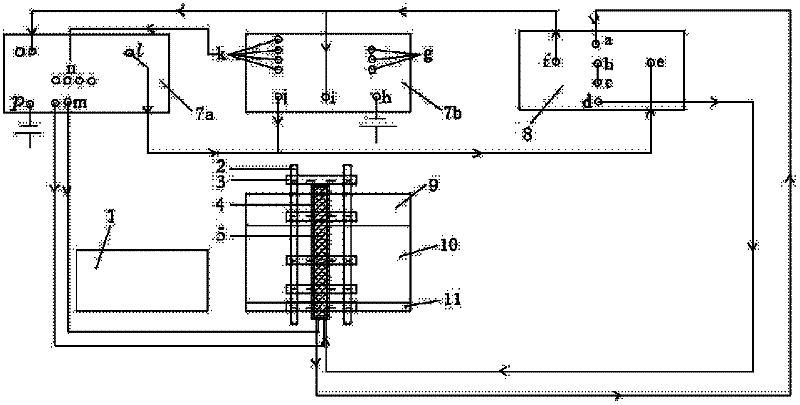

[0046] Place the normalizing heating equipment at the rail welding joint: the equipment is placed near the welding joint, and its d...

Embodiment 2

[0057] Welded joints are normalized (with air cooling). Use ZH-2 / 160KW fixed induction normalizing equipment to normalize the joints. When the temperature of the welded joint is lower than 500°C, the fixed induction normalizing equipment will normalize the joint and heat the rail weld to 900°C (±10°C). After heating to the specified temperature, cool with 0.13-0.15Mpa oil-free pressure air for 2 minutes. Improve the mechanical properties of the weld. Rail temperature control is measured by GD photoelectric thermometer (400°C-900°C). Through normalizing, the grains are refined; through rapid cooling, the mechanical performance indicators such as the hardness of the joint are improved.

Embodiment 3

[0059] Welded joints are normalized (natural cooling). The joints are normalized with oxy-acetylene flame normalizing equipment. When the temperature of the welded joint is lower than 500°C, the oxy-acetylene mixture combustion heating device is used to heat the rail weld to 900°C (±10°C). After heating to the specified temperature, it is naturally cooled to improve the mechanical properties of the weld. Rail temperature control is measured by GD photoelectric thermometer (400°C-900°C). Through normalizing, the grains are refined; through rapid cooling, the mechanical performance indicators such as the hardness of the joint are improved. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com