Saturated salt water drilling fluid for deep wells and extra-deep wells

A brine drilling fluid and ultra-deep well technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high solid content, unstable performance, and many treatment agents, and achieve strong anti-pollution ability, loss of life, etc. Good water wall building and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation method of deep well, ultra-deep well saturated brine drilling fluid

[0018] The preparation method of the deep well and ultra-deep well saturated brine drilling fluid is as follows: first use a measuring cylinder to measure 100 grams of tap water to control the water temperature at 70 °C, add 2 grams of bentonite under low-speed electric stirring, and add 5 grams of Na 2 CO 3 Stir for another 30 minutes, after prehydration at normal temperature and pressure for 24 hours, add 2 grams of maleic anhydride and stir for 5 minutes under low-speed electric stirring, add 0.4 grams of high-viscosity-polyanionic cellulose and stir for 5 minutes, add 8 grams of lignosulfonate Add 9 grams of sulfonated phenolic resin-lignosulfonate-humic acid copolymer and stir for 5 minutes, add 4 grams of emulsified asphalt and stir for 5 minutes, add 5 grams of C12-C18 linear alkane emulsion and stir for 5 minutes Add 2 grams of emulsified paraffin and stir for 5 ...

Embodiment 2

[0019] Embodiment 2: Evaluation of anti-pollution ability

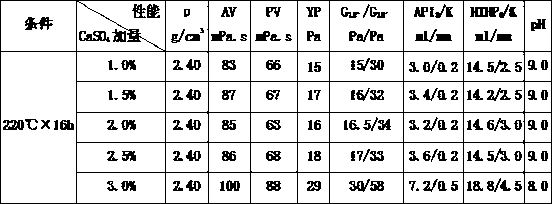

[0020] When drilling deep formations, gypsum layers, brine layers, cement plugs, etc. are often encountered, resulting in salt intrusion or calcium intrusion in the drilling fluid, resulting in a decrease in the density of the drilling fluid mud cake and an increase in permeability, and the quality of the mud cake deteriorates. The increase of filtration loss will eventually lead to the deterioration of drilling fluid rheology and water loss wall-building properties. At the same time, the poor quality of mud cake and large filtration loss will lead to instability of the well wall and aggravate the corrosion and damage to drilling tools. Therefore, , it is necessary to evaluate the salt resistance and calcium resistance of the system. Since the system of the present invention is a saturated brine system with good salt resistance, this example only evaluates the calcium resistance

[0021] Table 2 Anti-CaSO 4 Pollution...

Embodiment 3

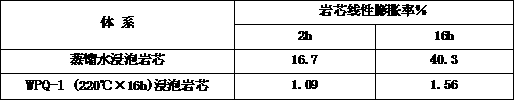

[0025] Example 3: Inhibition Evaluation

[0026] The inhibition of high-density water-based drilling fluid includes two aspects: one is the inhibition of cuttings intruding into high-density water-based drilling fluid; the other is to maintain the stability of the borehole wall. Usually, the former is evaluated by rolling recovery test , the latter is evaluated using linear expansion experiments

[0027] (1) Rolling recovery rate experiment

[0028] Table 3 Experimental results of rolling recovery rate

[0029] Drilling Fluid Formula Experimental conditions Recovery mass (g) Recovery rate(%) Distilled water + 50g cuttings 180℃×16h 14.98 30.0 WPQ-1+50g cuttings 180℃×16h 49.8 99.6

[0030] Note: 1. Cuttings are Sichuan red dust, drilling cuttings are 6-10 mesh, and the recovery rate is that of shale with 40 mesh; 2. The results in the table are the average value of 4 experimental data

[0031] The rolling recovery rate of the deep and ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com