Method for producing ammonium phosphate sulfate by S-NPK (Sulfur-Containing Nitrogen-Phosphorus-Potassium Compounds) device

A technology of ammonium thiophosphate and phosphoric acid, applied in fertilization device, application, fertilizer mixture and other directions, can solve problems such as process problems, and achieve the effect of reducing production cycle, reducing corrosion and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

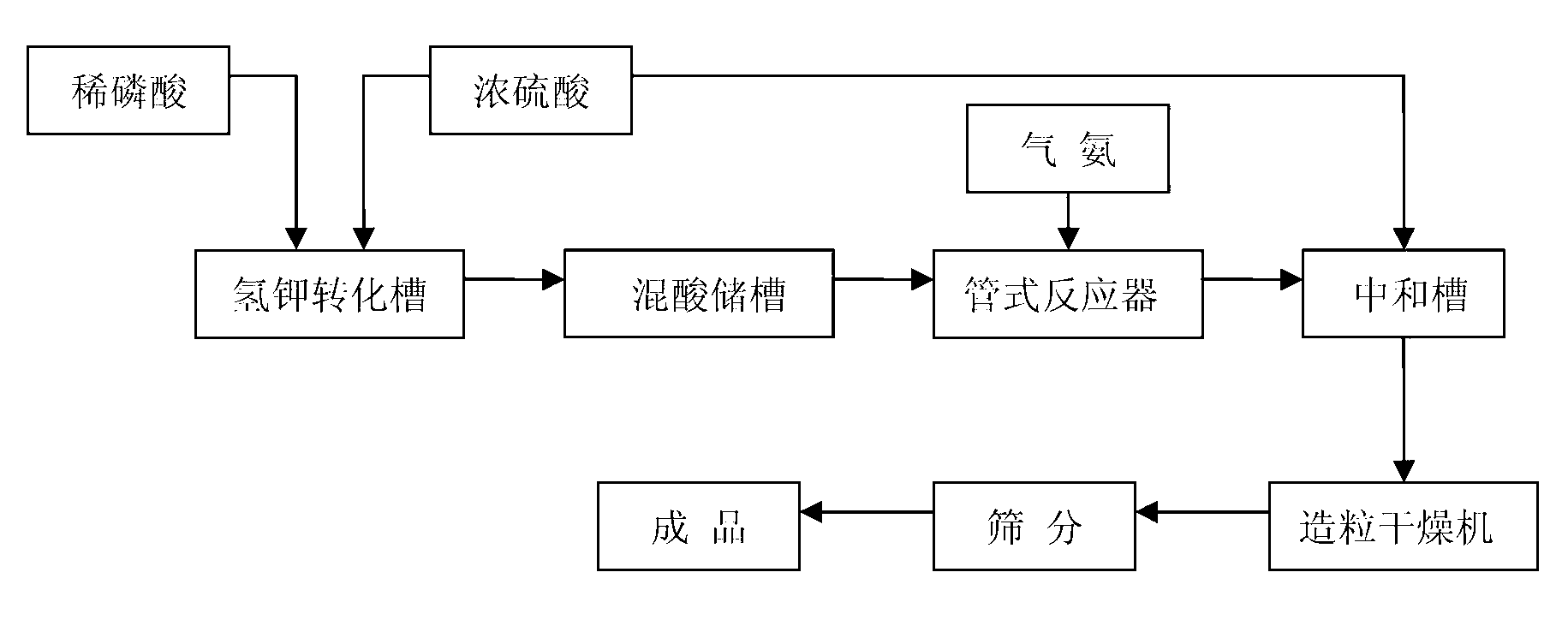

Image

Examples

Embodiment Construction

[0021] Reaction equation of the present invention is as follows:

[0022] 2NH 3 +H 2 SO 4 =(NH 4 ) 2 SO 4

[0023] 2NH 3 +H 3 PO 4 =(NH 4 ) 2 HPO 4

[0024] NH 3 +H 3 PO 4 =NH 4 h 2 PO 4

[0025] Using sulfur-based compound fertilizer (S-NPK) production equipment, the tail gas from the tubular reactor, neutralization tank and spray granulation is washed with dilute phosphoric acid, and the w(P 2 o 5 有效 ) is 17 to 21% of phosphoric acid and w (H 2 SO 4 ) is fully mixed with 98% concentrated sulfuric acid in the hydrogen potassium conversion tank. The temperature in the conversion tank is 95-100 °C. The mixed sulfur and phosphorus mixed acid enters the mixed acid storage tank and is pumped to the tubular reactor. Reaction in the reactor, the temperature in the tubular reactor is 105-115°C, the neutralization degree is controlled at 1.1-1.2, the mixed slurry obtained from the tubular reactor is neutralized with con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap