Fermenting device and fermenting method for soilless culture matrix

A soilless culture substrate and fermentation device technology, applied in fertilization devices, organic fertilizers, preparation of organic fertilizers, etc., can solve the problems of uneven and incomplete fermentation of materials, overflowing and overflowing fermentation water, etc., and reduce environmental pollution. The effect of pollution, avoiding impermeability of fermentation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

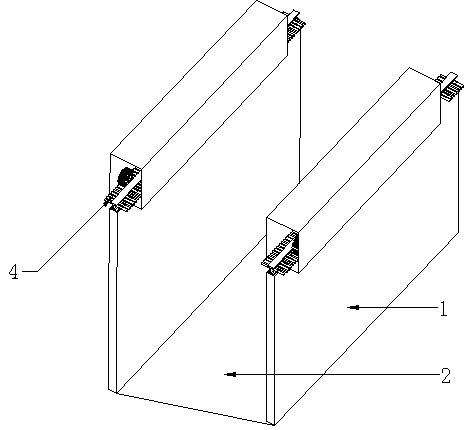

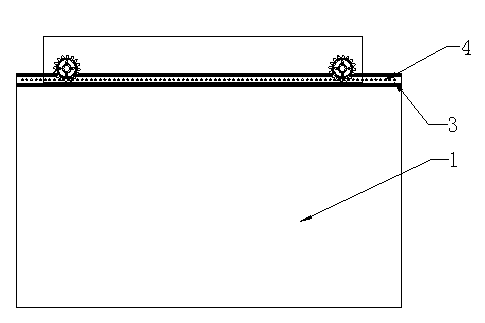

[0024] Build two conjoined fermentation tanks with a length of 50m, a width of 5m and a height of 1.0m. The bottom of the tank (2) is a cement floor with a thickness of 15cm, which can carry large-scale machinery; the thickness of the tank wall (1) is 24cm, and its strength requirements In order not to collapse when the tank is full of materials and mechanically turned over; each tank has 250m of one-time fermentation materials 3 about. The top of the trough wall (1) is installed with the running track matched with the turning machine; the running track is a number of round steel parts (4) with a diameter of 25mm and a height of 70mm (4) welded to the waists on both sides of the I-beam (3) to form a toothed conjoined structure , tooth pitch 70mm, the lower plane of the I-beam (3) is fixed on the top of the trough wall (1), and the upper plane becomes the mechanical walking track; the turning machine is erected on the running track of the trough wall to realize the driving of m...

Embodiment 2

[0032] Build 5 conjoined fermentation tanks with a length of 100m, a width of 5.5m and a height of 1.3m. The bottom of the tank (2) is a concrete floor with a thickness of 18cm, which can carry large-scale machinery; the thickness of the tank wall (1) is 37cm, and its strength The requirement is that it will not collapse when the tank is full of materials and mechanically turned over; the one-time fermented material in each tank is 700m 3 about. The top of the trough wall (1) is installed with the running track matched with the turning machine; the running track is a number of round steel parts (4) with a diameter of 35mm and a height of 80mm (4) welded on the I-beam (3) rail to form a toothed conjoined structure. The tooth pitch is 80mm, the lower plane of the I-beam (3) is fixed on the top of the trough wall (1), and the upper plane becomes the mechanical walking track; the turning machine is a driving-type special machine that runs on the running track of the trough wall to...

Embodiment 3

[0040] Build 8 conjoined fermentation tanks with a length of 150m, a width of 6m and a height of 1.5m. The bottom of the tank (2) is a cement floor with a thickness of 20cm, which can carry large-scale machinery; the thickness of the tank wall (1) is 50cm, and its strength requirements In order not to collapse when the tank is full of materials and mechanically turned over; each tank has a one-time fermentation material of 1350m 3 . The top of the trough wall is installed with the running track matched with the turning machine; the running track is a number of round steel parts (4) with a diameter of 50 mm and a height of 100 mm welded to the waists on both sides of the I-beam (3) to form a tooth-shaped conjoined structure. 100mm, the lower plane of the I-beam (3) is fixed on the top of the trough wall (1), and the upper plane becomes the mechanical walking track; Matches the fermenter width.

[0041] Utilize this fermenting device to carry out the method for substrate ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com