Method for preparing BaTiO3 conductive ceramic powder by taking water as medium through rare earth phase-phase permeation

A technology of conductive ceramics and ceramic powders, which is applied in the field of synthesis of inorganic nano-functional materials, can solve problems such as high cost and unfriendly environment, and achieve the effects of preventing pollution, low cost, and reducing modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The aforementioned BaTiO 3 The ceramic powder can be obtained by any preparation method in the prior art, and can also be purchased directly from the market. This embodiment provides a kind of BaTiO prepared by sol-gel method 3 Ceramic powder, the specific preparation method is: 1, 15.326g barium acetate is dissolved in deionized water, obtains the saturated solution of barium acetate; Add 20ml of glacial acetic acid to obtain a mixed system; 3. Add the saturated solution of barium acetate dropwise to the mixed system at a rate of less than 60 drops per minute to obtain a light yellow transparent solution. Dry for 72 hours to obtain the xerogel precursor; calcinate the xerogel precursor at 800°C for 2 hours to obtain pure BaTiO 3 ceramic powder.

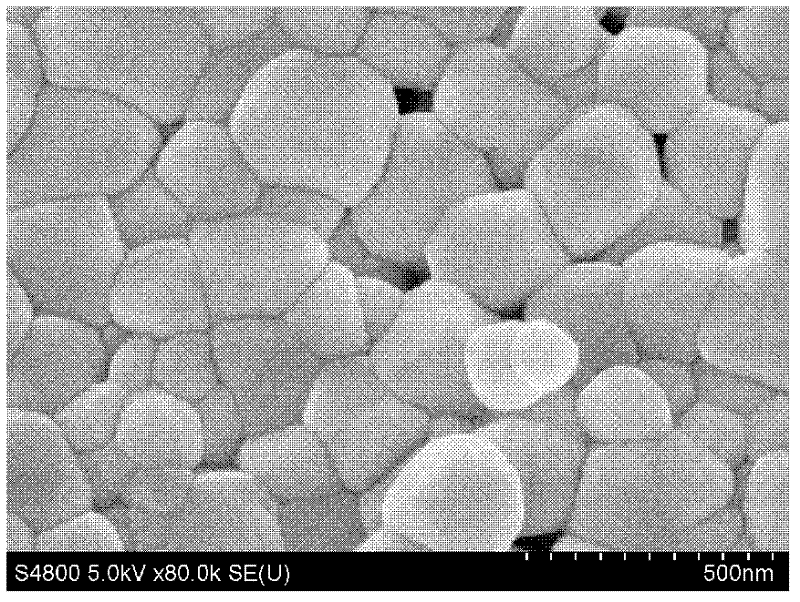

[0022] After testing, the obtained BaTiO 3 The room temperature resistivity of conductive ceramic powder is 2.98×10 -2 Ω·m, the average particle size is 200nm. The XRD diffraction pattern of the product is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com