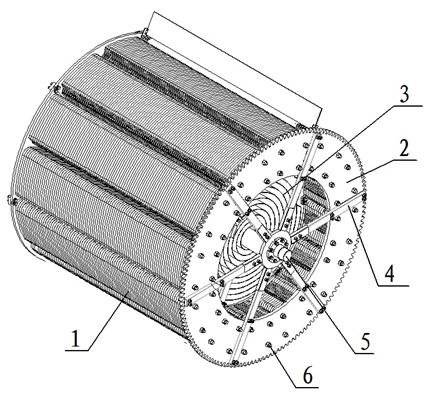

Self-aerated biofilm reactor and sewage treatment system applying same

A sewage treatment system and biological aeration technology, which can be applied in biological water/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc. The effect of saving resources and high processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

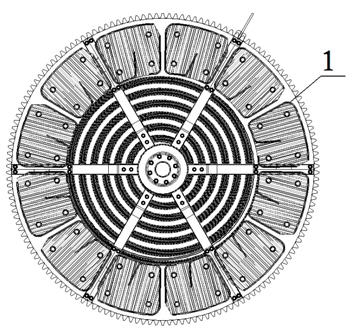

Method used

Image

Examples

Embodiment approach

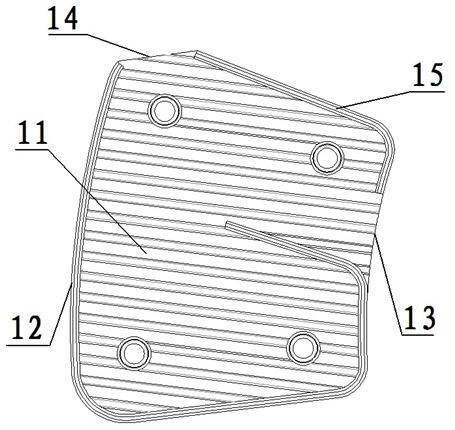

[0035] refer to image 3 , an embodiment of the disk unit, the disk is composed of a plurality of disk units 11 horizontally assembled together, the disk unit has a fan-shaped structure, the surface of the disk unit is concave-convex to form S-shaped corrugations, The edge is welded with a baffle 12 that is higher than the corrugation of the disc. The baffles located in the middle of the right side and the upper left corner of the disc respectively open to form an air outlet 13 and an air inlet 14. The baffle on the side of the air outlet faces the inside of the disc unit. Extending, the integral baffle forms a "G" shape on the surface of the disk unit, and a groove 15 is opened on the top of the baffle on one side of the disk unit.

[0036] The adsorption material is one of fiber bundle filler, fiber ball filler, paper laminated corrugated body filler, epoxy resin, unsaturated polyester resin glass fiber reinforced plastic, polypropylene and polyethylene.

[0037] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com