Mandril trolley cooling device for seamless steel tube puncher

A technology of ejector trolley and seamless steel pipe, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing manufacturing cost, reducing production efficiency, low production efficiency, etc., and reducing manufacturing cost and maintenance cost. The effect of reducing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

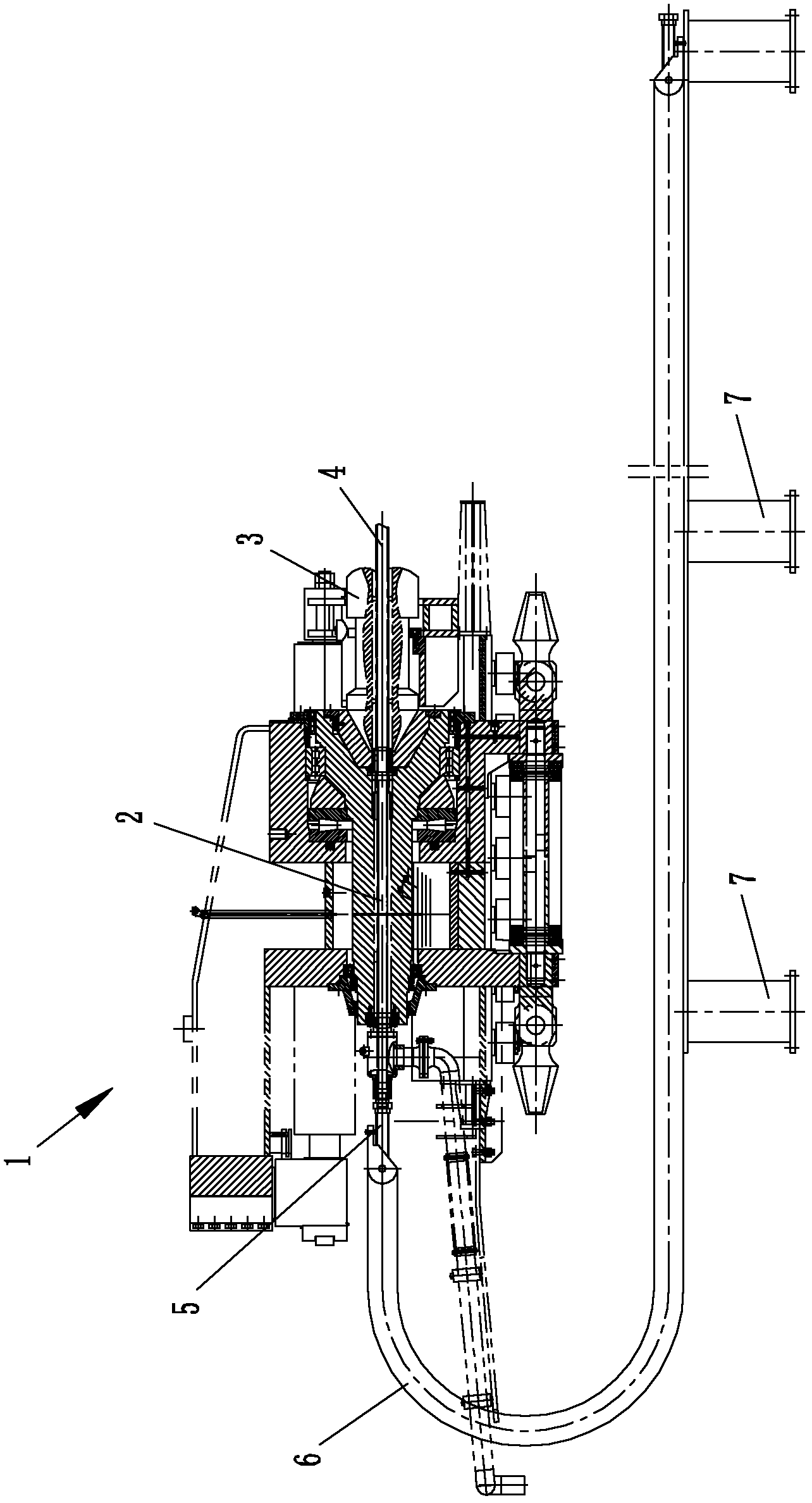

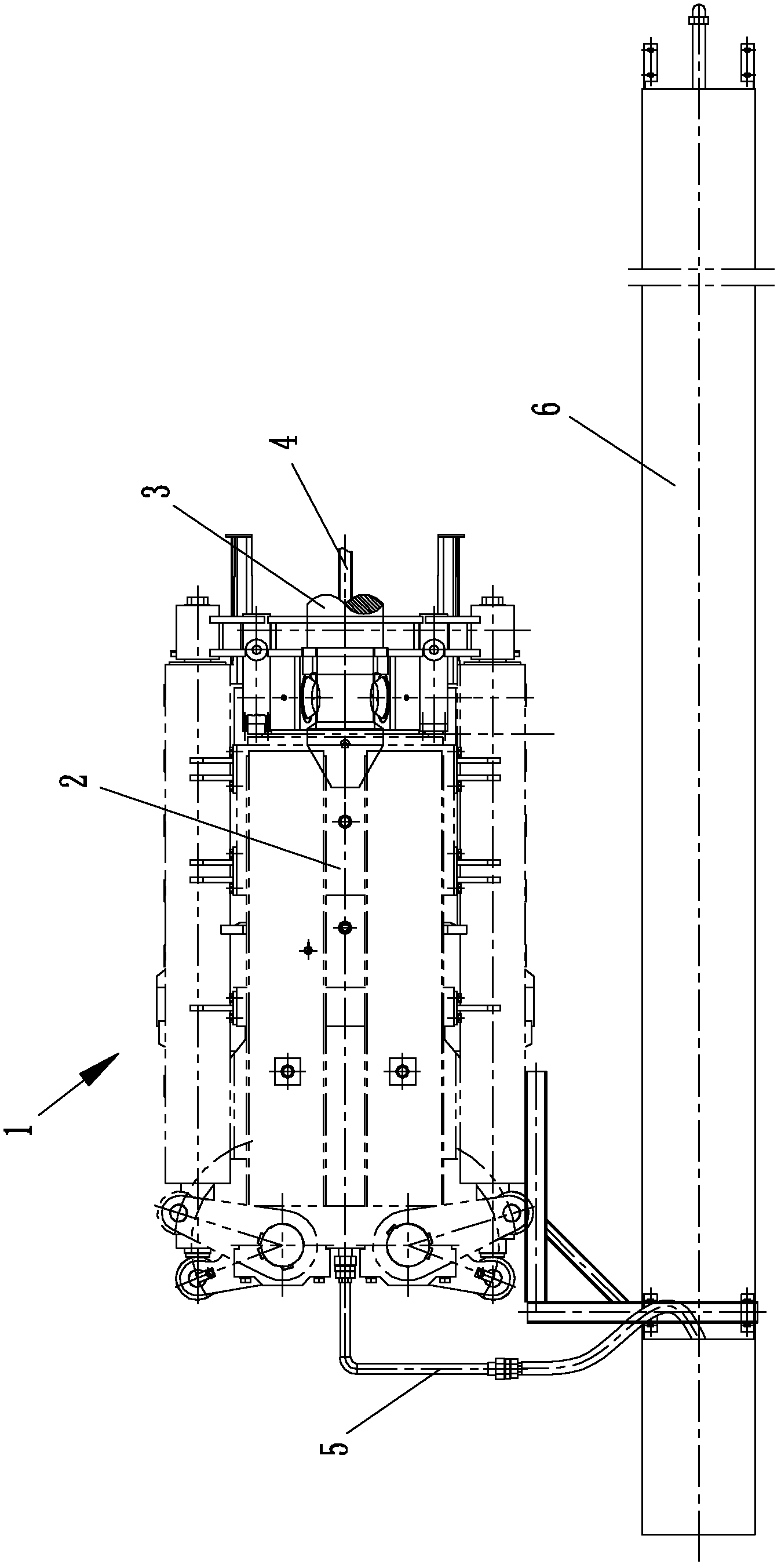

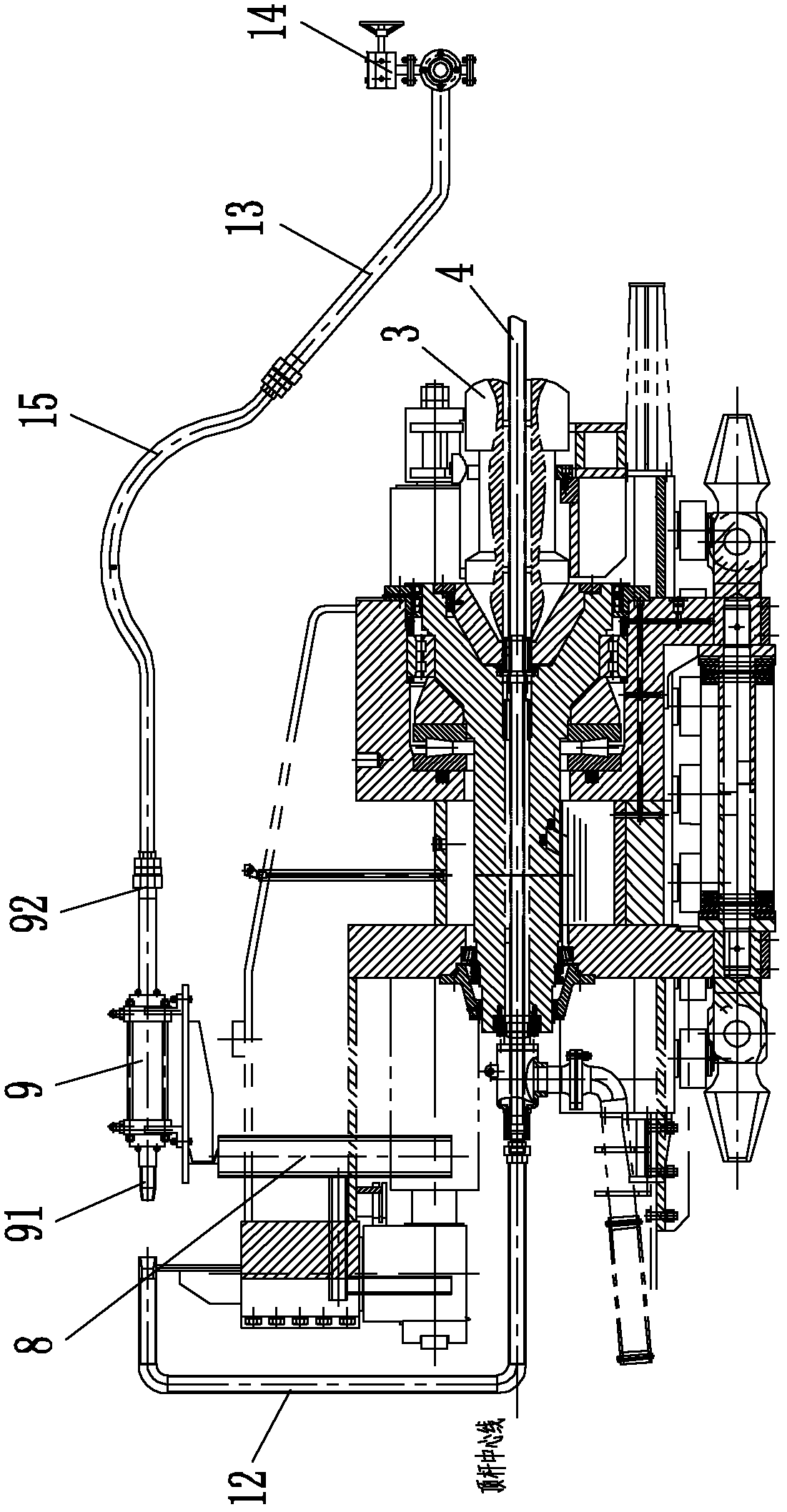

[0024] see Figure 3 to Figure 8 shown. The cooling device for the ejector trolley of the seamless steel pipe piercing machine of the present invention comprises the cooling water pipe 2 in the ejector trolley, the cooling water pipe 4 in the ejector rod, the connecting pipe 12, the cooling source water pipe 13, the cooling water hose 15, the cylinder bracket 8 and the cylinder 9.

[0025] The cooling water pipe 2 inside the ejector trolley is fixedly installed on the longitudinal centerline of the ejector trolley 1 , and the inner cooling water pipe 4 is arranged in the ejector rod 3 . The front end of the cooling water pipe 4 in the ejector rod extends forward to the position near the perforated head, and the tail end of the cooling water pipe 4 in the ejector rod is connected to the front end of the cooling water pipe 2 in the ejector trolley. Preferably, the cooling water pipe 2 in the ejector trolley and The cooling water pipes 4 in the mandrel are located on the same c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com